Question: Spare part management: maximizing the supply availability In this assignment, we will consider the supply availability of the real-time tactical reconnaissance system (Reccelite). The Reccelite

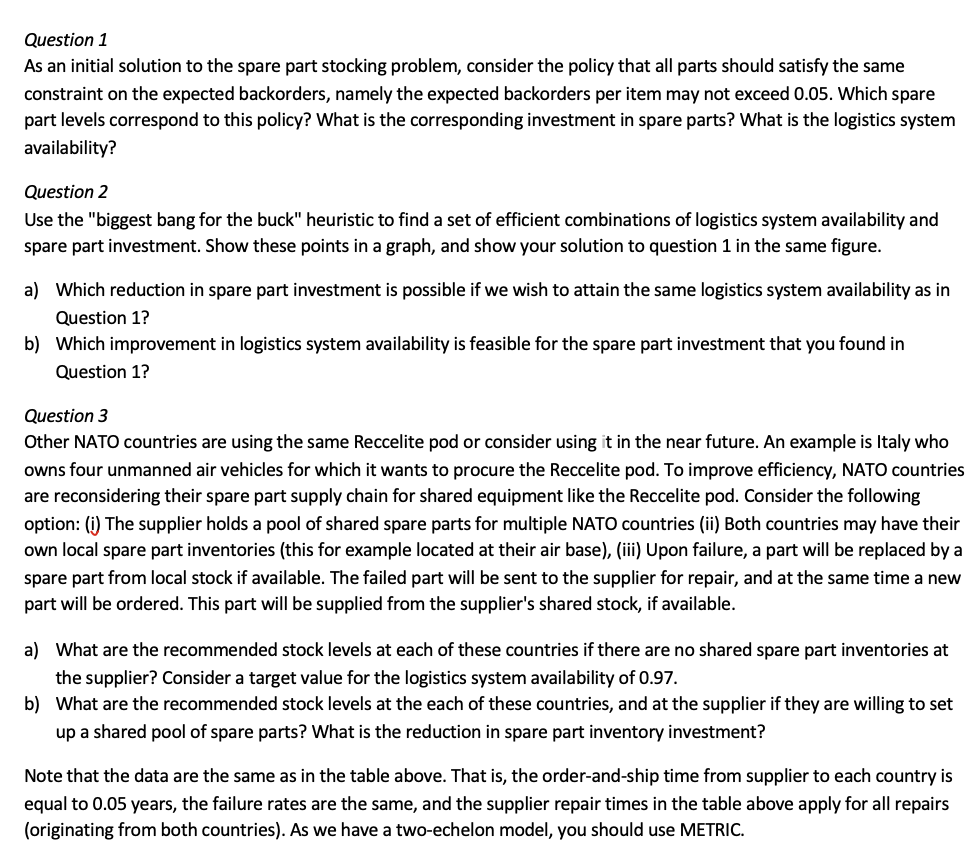

Spare part management: maximizing the supply availability In this assignment, we will consider the supply availability of the real-time tactical reconnaissance system (Reccelite). The Reccelite is an electro-optical (Infra-Red+CCD-TV) tactical reconnaissance pod designed to operate 24 hours a day in adverse weather conditions, see separate leaflet for detailed system characteristics. The Ministry of Defense of NATO country on behalf of its Royal Air Force signed a $40 million contract for Reccelite reconnaissance pods few years ago. This equipment was installed at military aircraft for surveillance purposes. The Royal Airforce owns and uses 6 pods. All pods are maintained at a single location, namely in the Air Force base. Five critical parts of the Reccelite pod are maintained by replacement upon failure. Each pod contains exactly one piece of each critical part. Failed parts are repaired at the supplier, and the repair lead times tend to be long. Currently, the Airforce does not have its own facilities to perform repairs on the Reccelite pod. The table below gives the key part characteristics. Note that the supplier repair lead time is defined as the time between failure at the base and the completion of the repair of the supplier. So, the repair lead time covers (i) the time to ship the failed parts from the base to the supplier, and (ii) the repair throughput time at the supplier. The order-and-ship time is the time needed to send an as-good-asnew part from the supplier to the base. Question 1 As an initial solution to the spare part stocking problem, consider the policy that all parts should satisfy the same constraint on the expected backorders, namely the expected backorders per item may not exceed 0.05 . Which spare part levels correspond to this policy? What is the corresponding investment in spare parts? What is the logistics system availability? Question 2 Use the "biggest bang for the buck" heuristic to find a set of efficient combinations of logistics system availability and spare part investment. Show these points in a graph, and show your solution to question 1 in the same figure. a) Which reduction in spare part investment is possible if we wish to attain the same logistics system availability as in Question 1? b) Which improvement in logistics system availability is feasible for the spare part investment that you found in Question 1? Question 3 Other NATO countries are using the same Reccelite pod or consider using it in the near future. An example is Italy who owns four unmanned air vehicles for which it wants to procure the Reccelite pod. To improve efficiency, NATO countries are reconsidering their spare part supply chain for shared equipment like the Reccelite pod. Consider the following option: (i) The supplier holds a pool of shared spare parts for multiple NATO countries (ii) Both countries may have their own local spare part inventories (this for example located at their air base), (iii) Upon failure, a part will be replaced by a spare part from local stock if available. The failed part will be sent to the supplier for repair, and at the same time a new part will be ordered. This part will be supplied from the supplier's shared stock, if available. a) What are the recommended stock levels at each of these countries if there are no shared spare part inventories at the supplier? Consider a target value for the logistics system availability of 0.97 . b) What are the recommended stock levels at the each of these countries, and at the supplier if they are willing to set up a shared pool of spare parts? What is the reduction in spare part inventory investment? Note that the data are the same as in the table above. That is, the order-and-ship time from supplier to each country is equal to 0.05 years, the failure rates are the same, and the supplier repair times in the table above apply for all repairs (originating from both countries). As we have a two-echelon model, you should use METRIC

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts