Question: Special Problem 2: This problem is a continuation of the process described in Example 4.3 described on pages 83-84 of the textbook. You need to

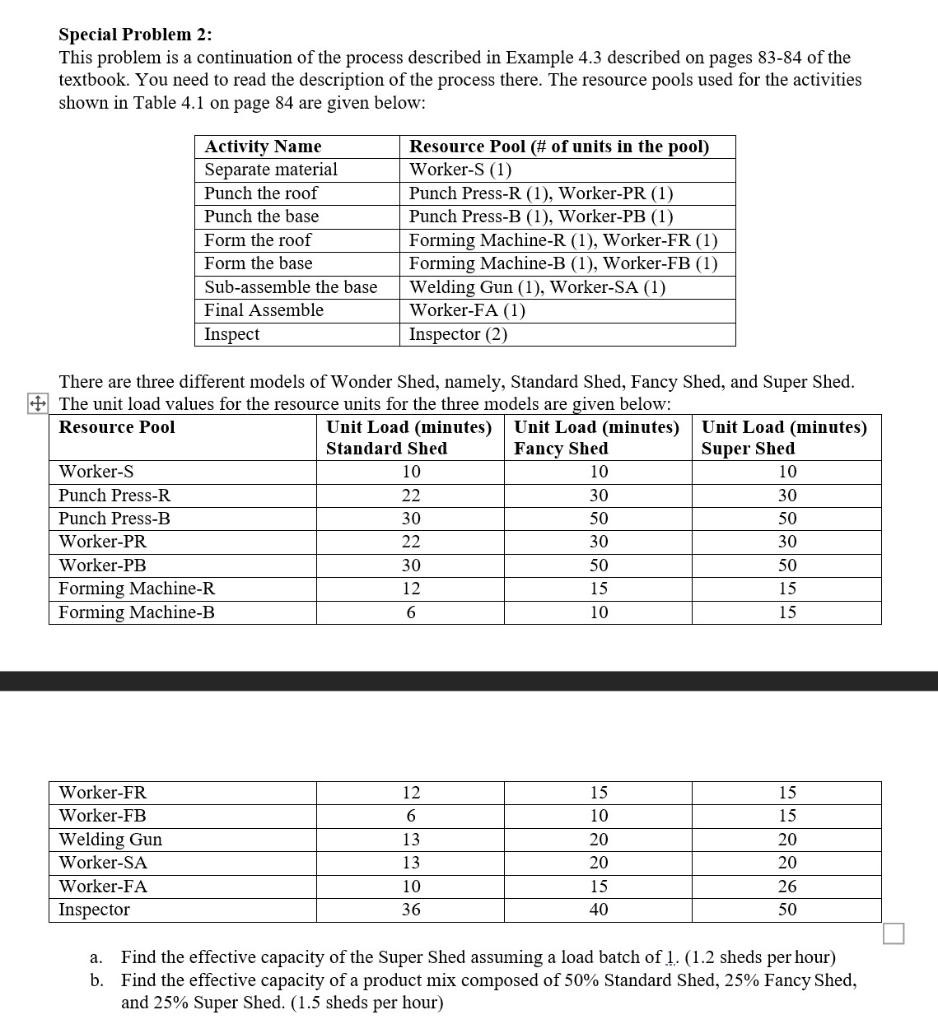

Special Problem 2: This problem is a continuation of the process described in Example 4.3 described on pages 83-84 of the textbook. You need to read the description of the process there. The resource pools used for the activities shown in Table 4.1 on page 84 are given below: Activity Name Separate material Punch the roof Punch the base Form the roof Form the base Sub-assemble the base Final Assemble Inspect Resource Pool (# of units in the pool) Worker-S (1) Punch Press-R (1), Worker-PR (1) Punch Press-B (1), Worker-PB (1) Forming Machine-R (1), Worker-FR (1) Forming Machine-B (1), Worker-FB (1) Welding Gun (1), Worker-SA (1) Worker-FA (1) Inspector (2) There are three different models of Wonder Shed, namely, Standard Shed, Fancy Shed, and Super Shed. + The unit load values for the resource units for the three models are given below: Resource Pool Unit Load (minutes) Unit Load (minutes) Unit Load (minutes) Standard Shed Fancy Shed Super Shed Worker-S 10 10 10 Punch Press-R 22 30 30 Punch Press-B 30 50 50 Worker-PR 22 30 30 Worker-PB 30 50 50 Forming Machine-R 12 15 15 Forming Machine-B 6 10 15 12 15 6 Worker-FR Worker-FB Welding Gun Worker-SA Worker-FA Inspector 13 13 10 20 20 15 15 20 20 26 50 10 15 36 40 a. Find the effective capacity of the Super Shed assuming a load batch of 1. (1.2 sheds per hour) b. Find the effective capacity of a product mix composed of 50% Standard Shed, 25% Fancy Shed, and 25% Super Shed. (1.5 sheds per hour) EXAMPLE 4.3 To illustrate the function of a simple process flowchart, consider the manufacturing process at Wonder Shed Inc., a manufacturer of storage sheds. The manufacturing process involves the procurement of sheets of steel that will be used to form both the roof and the base of each shed. The first step involves separating the material needed for the roof from that needed for the base. Then the roof and the base can be fabricated in parallel, or simulta- neously. Roof fabrication involves first punching then forming the roof to shape. Base fabrication entails the punching-and-forming process plus a subassembly operation. Fabricated roofs and bases are then assembled into finished sheds that are subsequently inspected for quality assurance. A list of activities needed to fabricate a roof, fabricate a base, and assemble a shed is given in Table 4.1. A flowchart of the process is shown in Figure 4:1. Special Problem 2: This problem is a continuation of the process described in Example 4.3 described on pages 83-84 of the textbook. You need to read the description of the process there. The resource pools used for the activities shown in Table 4.1 on page 84 are given below: Activity Name Separate material Punch the roof Punch the base Form the roof Form the base Sub-assemble the base Final Assemble Inspect Resource Pool (# of units in the pool) Worker-S (1) Punch Press-R (1), Worker-PR (1) Punch Press-B (1), Worker-PB (1) Forming Machine-R (1), Worker-FR (1) Forming Machine-B (1), Worker-FB (1) Welding Gun (1), Worker-SA (1) Worker-FA (1) Inspector (2) There are three different models of Wonder Shed, namely, Standard Shed, Fancy Shed, and Super Shed. + The unit load values for the resource units for the three models are given below: Resource Pool Unit Load (minutes) Unit Load (minutes) Unit Load (minutes) Standard Shed Fancy Shed Super Shed Worker-S 10 10 10 Punch Press-R 22 30 30 Punch Press-B 30 50 50 Worker-PR 22 30 30 Worker-PB 30 50 50 Forming Machine-R 12 15 15 Forming Machine-B 6 10 15 12 15 6 Worker-FR Worker-FB Welding Gun Worker-SA Worker-FA Inspector 13 13 10 20 20 15 15 20 20 26 50 10 15 36 40 a. Find the effective capacity of the Super Shed assuming a load batch of 1. (1.2 sheds per hour) b. Find the effective capacity of a product mix composed of 50% Standard Shed, 25% Fancy Shed, and 25% Super Shed. (1.5 sheds per hour) EXAMPLE 4.3 To illustrate the function of a simple process flowchart, consider the manufacturing process at Wonder Shed Inc., a manufacturer of storage sheds. The manufacturing process involves the procurement of sheets of steel that will be used to form both the roof and the base of each shed. The first step involves separating the material needed for the roof from that needed for the base. Then the roof and the base can be fabricated in parallel, or simulta- neously. Roof fabrication involves first punching then forming the roof to shape. Base fabrication entails the punching-and-forming process plus a subassembly operation. Fabricated roofs and bases are then assembled into finished sheds that are subsequently inspected for quality assurance. A list of activities needed to fabricate a roof, fabricate a base, and assemble a shed is given in Table 4.1. A flowchart of the process is shown in Figure 4:1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts