Question: Step by Step on how to create a sensitivity report for the following case study. Case Study: Optimization OPTIMAL FASHIONS From the CEO chair in

Step by Step on how to create a sensitivity report for the following case study.

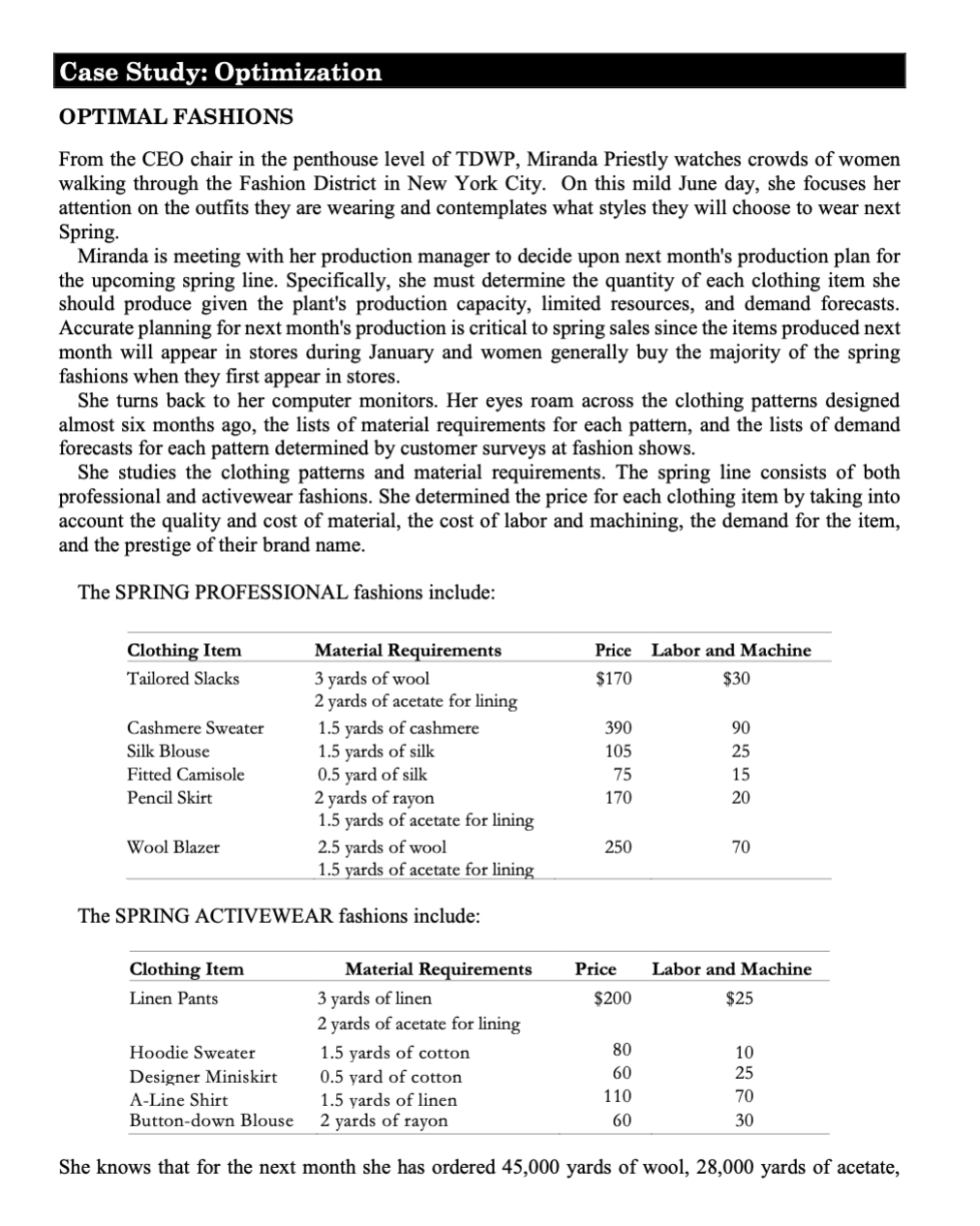

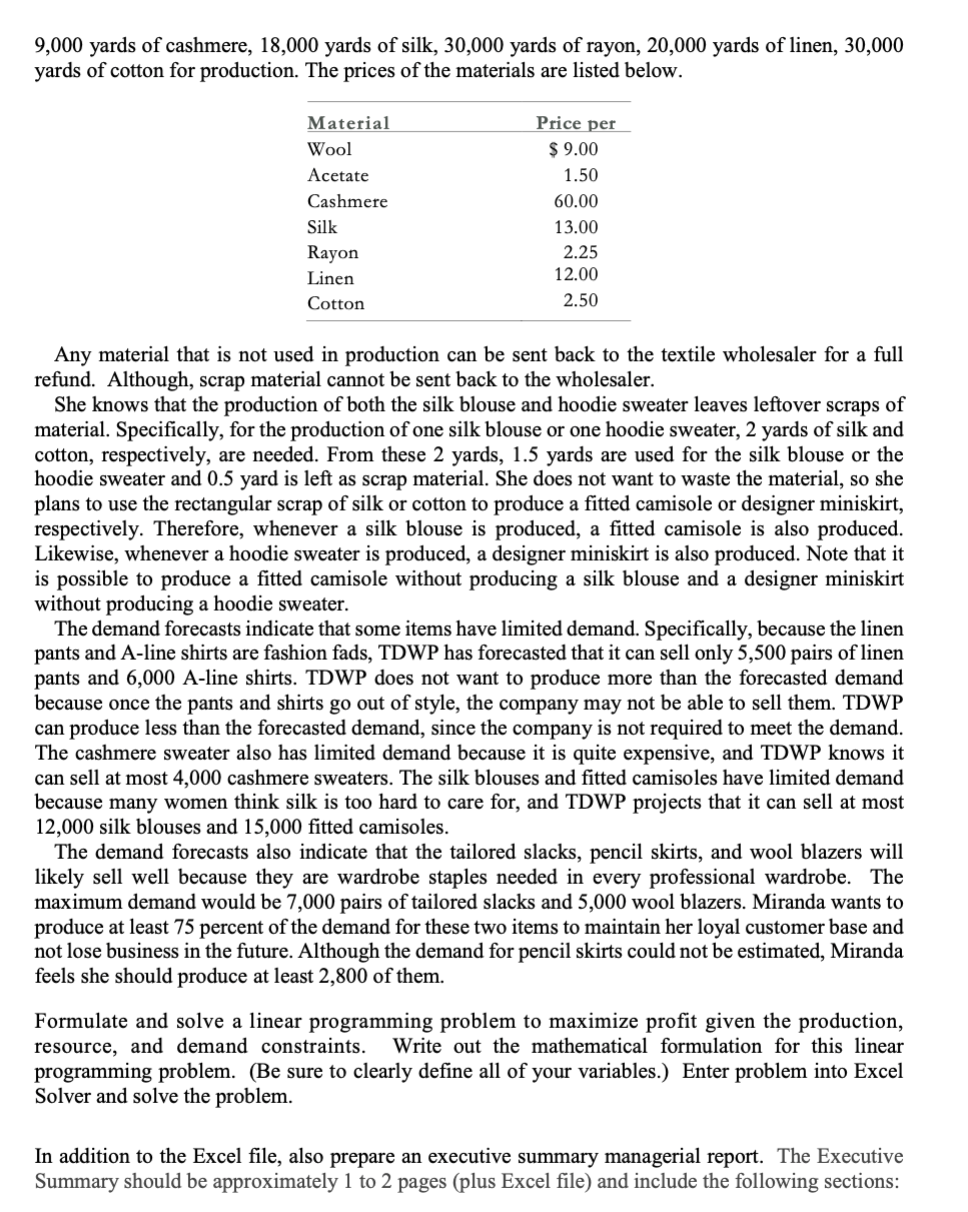

Case Study: Optimization OPTIMAL FASHIONS From the CEO chair in the penthouse level of TDWP, Miranda Priestly watches crowds of women walking through the Fashion District in New York City. On this mild June day, she focuses her attention on the outfits they are wearing and contemplates what styles they will choose to wear next Spring. Miranda is meeting with her production manager to decide upon next month's production plan for the upcoming spring line. Specifically, she must determine the quantity of each clothing item she should produce given the plant's production capacity, limited resources, and demand forecasts. Accurate planning for next month's production is critical to spring sales since the items produced next month will appear in stores during January and women generally buy the majority of the spring fashions when they first appear in stores. She turns back to her computer monitors. Her eyes roam across the clothing patterns designed almost six months ago, the lists of material requirements for each pattern, and the lists of demand forecasts for each pattern determined by customer surveys at fashion shows. She studies the clothing patterns and material requirements. The spring line consists of both professional and activewear fashions. She determined the price for each clothing item by taking into account the quality and cost of material, the cost of labor and machining, the demand for the item, and the prestige of their brand name. The SPRING PROFESSIONAL fashions include: The SPRING ACTIVEWEAR fashions include: She knows that for the next month she has ordered 45,000 yards of wool, 28,000 yards of acetate, 9,000 yards of cashmere, 18,000 yards of silk, 30,000 yards of rayon, 20,000 yards of linen, 30,000 yards of cotton for production. The prices of the materials are listed below. Any material that is not used in production can be sent back to the textile wholesaler for a full refund. Although, scrap material cannot be sent back to the wholesaler. She knows that the production of both the silk blouse and hoodie sweater leaves leftover scraps of material. Specifically, for the production of one silk blouse or one hoodie sweater, 2 yards of silk and cotton, respectively, are needed. From these 2 yards, 1.5 yards are used for the silk blouse or the hoodie sweater and 0.5 yard is left as scrap material. She does not want to waste the material, so she plans to use the rectangular scrap of silk or cotton to produce a fitted camisole or designer miniskirt, respectively. Therefore, whenever a silk blouse is produced, a fitted camisole is also produced. Likewise, whenever a hoodie sweater is produced, a designer miniskirt is also produced. Note that it is possible to produce a fitted camisole without producing a silk blouse and a designer miniskirt without producing a hoodie sweater. The demand forecasts indicate that some items have limited demand. Specifically, because the linen pants and A-line shirts are fashion fads, TDWP has forecasted that it can sell only 5,500 pairs of linen pants and 6,000 A-line shirts. TDWP does not want to produce more than the forecasted demand because once the pants and shirts go out of style, the company may not be able to sell them. TDWP can produce less than the forecasted demand, since the company is not required to meet the demand. The cashmere sweater also has limited demand because it is quite expensive, and TDWP knows it can sell at most 4,000 cashmere sweaters. The silk blouses and fitted camisoles have limited demand because many women think silk is too hard to care for, and TDWP projects that it can sell at most 12,000 silk blouses and 15,000 fitted camisoles. The demand forecasts also indicate that the tailored slacks, pencil skirts, and wool blazers will likely sell well because they are wardrobe staples needed in every professional wardrobe. The maximum demand would be 7,000 pairs of tailored slacks and 5,000 wool blazers. Miranda wants to produce at least 75 percent of the demand for these two items to maintain her loyal customer base and not lose business in the future. Although the demand for pencil skirts could not be estimated, Miranda feels she should produce at least 2,800 of them. Formulate and solve a linear programming problem to maximize profit given the production, resource, and demand constraints. Write out the mathematical formulation for this linear programming problem. (Be sure to clearly define all of your variables.) Enter problem into Excel Solver and solve the problem. In addition to the Excel file, also prepare an executive summary managerial report. The Executive Summary should be approximately 1 to 2 pages (plus Excel file) and include the following sections

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts