Question: Student Name: Student Number: Section Number: Question Maximum Mark Mark Obtained 1 4 2 4 3 4 4 4 5 4 4 6 7 4

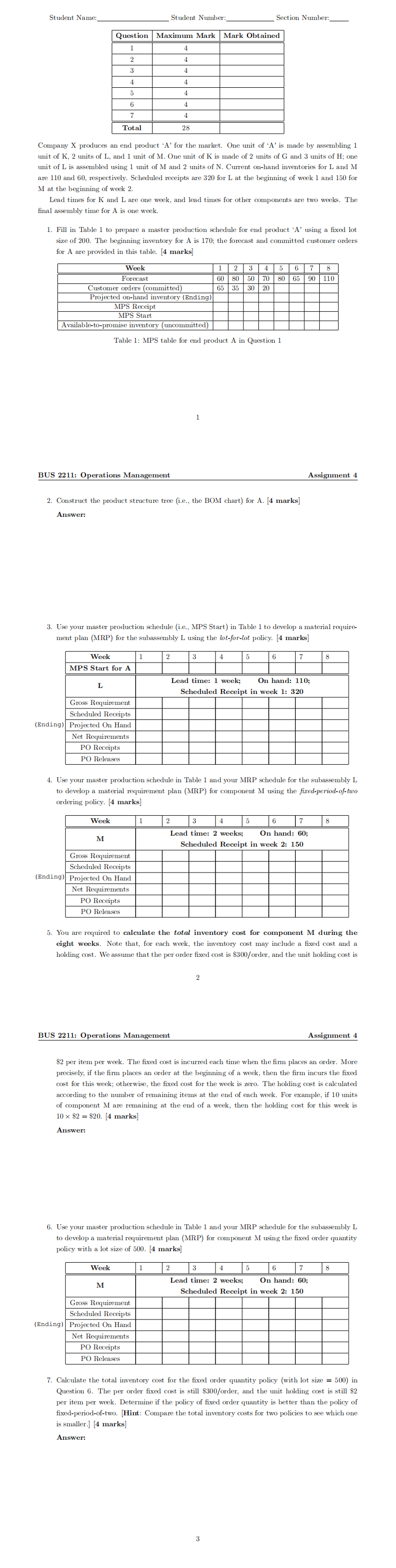

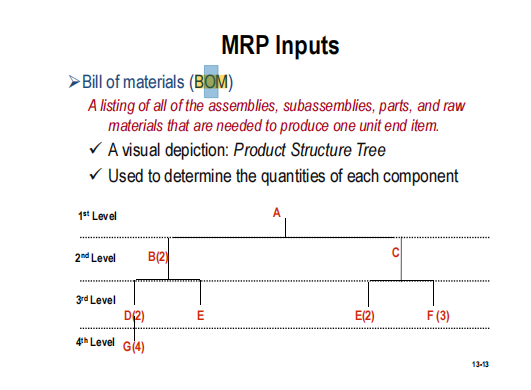

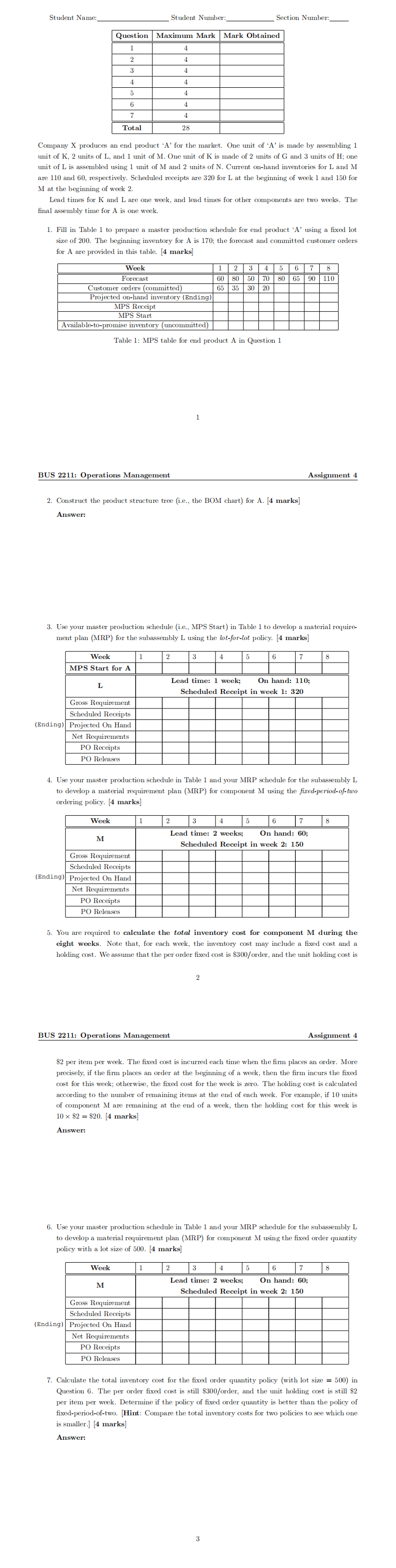

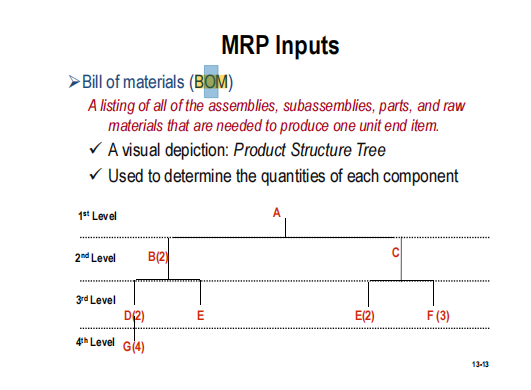

Student Name: Student Number: Section Number: Question Maximum Mark Mark Obtained 1 4 2 4 3 4 4 4 5 4 4 6 7 4 Total 28 Company X produces an end product 'A' for the market. One unit of 'A' is made by assembling 1 unit of K, 2 units of L, and 1 unit of M. One unit of K is made of 2 units of G and 3 units of H; one unit of L is assembled using 1 unit of M and 2 units of N. Current on-hand inventories for L and M are 110 and 60, respectively. Scheduled receipts are 320 for L at the beginning of week 1 and 150 for M at the beginning of week 2. Lead times for K and L are one week, and lead times for other components are two weeks. The final assembly time for A is one week. 1. Fill in Table 1 to prepare a master production schedule for end product 'A' using a fixed lot size of 200. The beginning inventory for A is 170; the forecast and committed customer orders for A are provided in this table. [4 marks) 2 4 6 7 8 65 90 110 Week 1 3 5 Forecast 60 80 50 70 80 Customer orders (committed) 65 35 30 20 Projected on-hand inventory (Ending) MPS Receipt MPS Start Available-to-promise inventory (uncommitted) Table 1: MPS table for end product A in Question 1 1 BUS 2211: Operations Management Assignment 4 2. Construct the product structure tree (i.e., the BOM chart) for A. (4 marks] Answer: 3. Use your master production schedule (i.e., MPS Start) in Table 1 to develop a material require- ment plan (MRP) for the subassembly L using the lot-for-lot policy. (4 marks] 1 2 3 4 5 6 7 8 Week MPS Start for A L Lead time: 1 week; On hand: 110; Scheduled Receipt in week 1: 320 Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 4. Use your master production schedule in Table 1 and your MRP schedule for the subassembly L to develop a material requirement plan (MRP) for component M using the fixed-period-of-two ordering policy. (4 marks) Week 1 8 2 3 4 5 6 7 Lead time: 2 weeks; On hand: 60; Scheduled Receipt in week 2: 150 M Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 5. You are required to calculate the total inventory cost for component M during the eight weeks. Note that, for each week, the inventory cost may include a fixed cost and a holding cost. We assume that the per order fixed cost is $300/order, and the unit holding cost is 2 BUS 2211: Operations Management Assignment 4 $2 per item per week. The fixed cost is incurred each time when the firm places an order. More precisely, if the firm places an order at the beginning of a week, then the firm incurs the fixed cost for this week; otherwise, the fixed cost for the week is zero. The holding cost is calculated according to the number of remaining items at the end of each week. For example, if 10 units of component M are remaining at the end of a week, then the holding cost for this week is 10 x $2 = $20. (4 marks] Answer: 6. Use your master production schedule in Table 1 and your MRP schedule for the subassembly L to develop a material requirement plan (MRP) for component M using the fixed order quantity policy with a lot size of 500. (4 marks] Week 1 8 2 3 4 5 6 7 Lead time: 2 weeks; On hand: 60; Scheduled Receipt in week 2: 150 M Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 7. Calculate the total inventory cost for the fixed order quantity policy (with lot size = 500) in Question 6. The per order fixed cost is still $300/order, and the unit holding cost is still $2 per item per week. Determine if the policy of fixed order quantity is better than the policy of fixed-period-of-two. (Hint: Compare the total inventory costs for two policies to see which one is smaller.) (4 marks) Answer: 3 MRP Inputs > Bill of materials (BOM) A listing of all of the assemblies, subassemblies, parts, and raw materials that are needed to produce one unit end item. A visual depiction: Product Structure Tree Used to determine the quantities of each component 1st Level 2nd Level B(2) 3rd Level D(2) E E) E(2) F(3) 4th Level G|4) 13-13 Student Name: Student Number: Section Number: Question Maximum Mark Mark Obtained 1 4 2 4 3 4 4 4 5 4 4 6 7 4 Total 28 Company X produces an end product 'A' for the market. One unit of 'A' is made by assembling 1 unit of K, 2 units of L, and 1 unit of M. One unit of K is made of 2 units of G and 3 units of H; one unit of L is assembled using 1 unit of M and 2 units of N. Current on-hand inventories for L and M are 110 and 60, respectively. Scheduled receipts are 320 for L at the beginning of week 1 and 150 for M at the beginning of week 2. Lead times for K and L are one week, and lead times for other components are two weeks. The final assembly time for A is one week. 1. Fill in Table 1 to prepare a master production schedule for end product 'A' using a fixed lot size of 200. The beginning inventory for A is 170; the forecast and committed customer orders for A are provided in this table. [4 marks) 2 4 6 7 8 65 90 110 Week 1 3 5 Forecast 60 80 50 70 80 Customer orders (committed) 65 35 30 20 Projected on-hand inventory (Ending) MPS Receipt MPS Start Available-to-promise inventory (uncommitted) Table 1: MPS table for end product A in Question 1 1 BUS 2211: Operations Management Assignment 4 2. Construct the product structure tree (i.e., the BOM chart) for A. (4 marks] Answer: 3. Use your master production schedule (i.e., MPS Start) in Table 1 to develop a material require- ment plan (MRP) for the subassembly L using the lot-for-lot policy. (4 marks] 1 2 3 4 5 6 7 8 Week MPS Start for A L Lead time: 1 week; On hand: 110; Scheduled Receipt in week 1: 320 Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 4. Use your master production schedule in Table 1 and your MRP schedule for the subassembly L to develop a material requirement plan (MRP) for component M using the fixed-period-of-two ordering policy. (4 marks) Week 1 8 2 3 4 5 6 7 Lead time: 2 weeks; On hand: 60; Scheduled Receipt in week 2: 150 M Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 5. You are required to calculate the total inventory cost for component M during the eight weeks. Note that, for each week, the inventory cost may include a fixed cost and a holding cost. We assume that the per order fixed cost is $300/order, and the unit holding cost is 2 BUS 2211: Operations Management Assignment 4 $2 per item per week. The fixed cost is incurred each time when the firm places an order. More precisely, if the firm places an order at the beginning of a week, then the firm incurs the fixed cost for this week; otherwise, the fixed cost for the week is zero. The holding cost is calculated according to the number of remaining items at the end of each week. For example, if 10 units of component M are remaining at the end of a week, then the holding cost for this week is 10 x $2 = $20. (4 marks] Answer: 6. Use your master production schedule in Table 1 and your MRP schedule for the subassembly L to develop a material requirement plan (MRP) for component M using the fixed order quantity policy with a lot size of 500. (4 marks] Week 1 8 2 3 4 5 6 7 Lead time: 2 weeks; On hand: 60; Scheduled Receipt in week 2: 150 M Gross Requirement Scheduled Receipts (Ending) Projected On Hand Net Requirements PO Receipts PO Releases 7. Calculate the total inventory cost for the fixed order quantity policy (with lot size = 500) in Question 6. The per order fixed cost is still $300/order, and the unit holding cost is still $2 per item per week. Determine if the policy of fixed order quantity is better than the policy of fixed-period-of-two. (Hint: Compare the total inventory costs for two policies to see which one is smaller.) (4 marks) Answer: 3 MRP Inputs > Bill of materials (BOM) A listing of all of the assemblies, subassemblies, parts, and raw materials that are needed to produce one unit end item. A visual depiction: Product Structure Tree Used to determine the quantities of each component 1st Level 2nd Level B(2) 3rd Level D(2) E E) E(2) F(3) 4th Level G|4) 13-13