Question: Subject: Human Resource Management This is a case study : Now solve this : Considering the job descriptions provided in the case (Exhibit 2), identify

Subject: Human Resource Management

This is a case study :

Now solve this :

Considering the job descriptions provided in the case (Exhibit 2), identify the compensable factors (for any two jobs among the given 3 job descriptions) for a Point-system based job evaluation plan. Provide justification to use those compensable factors along with their weights

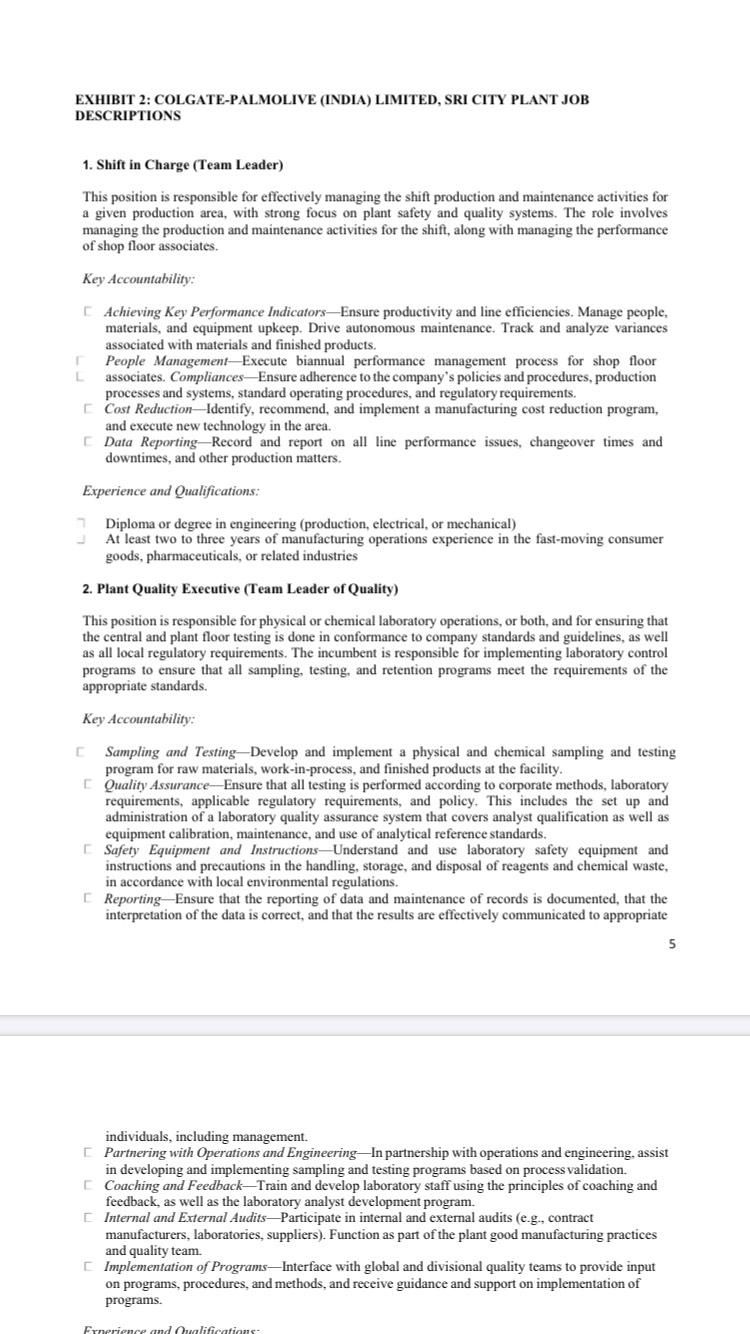

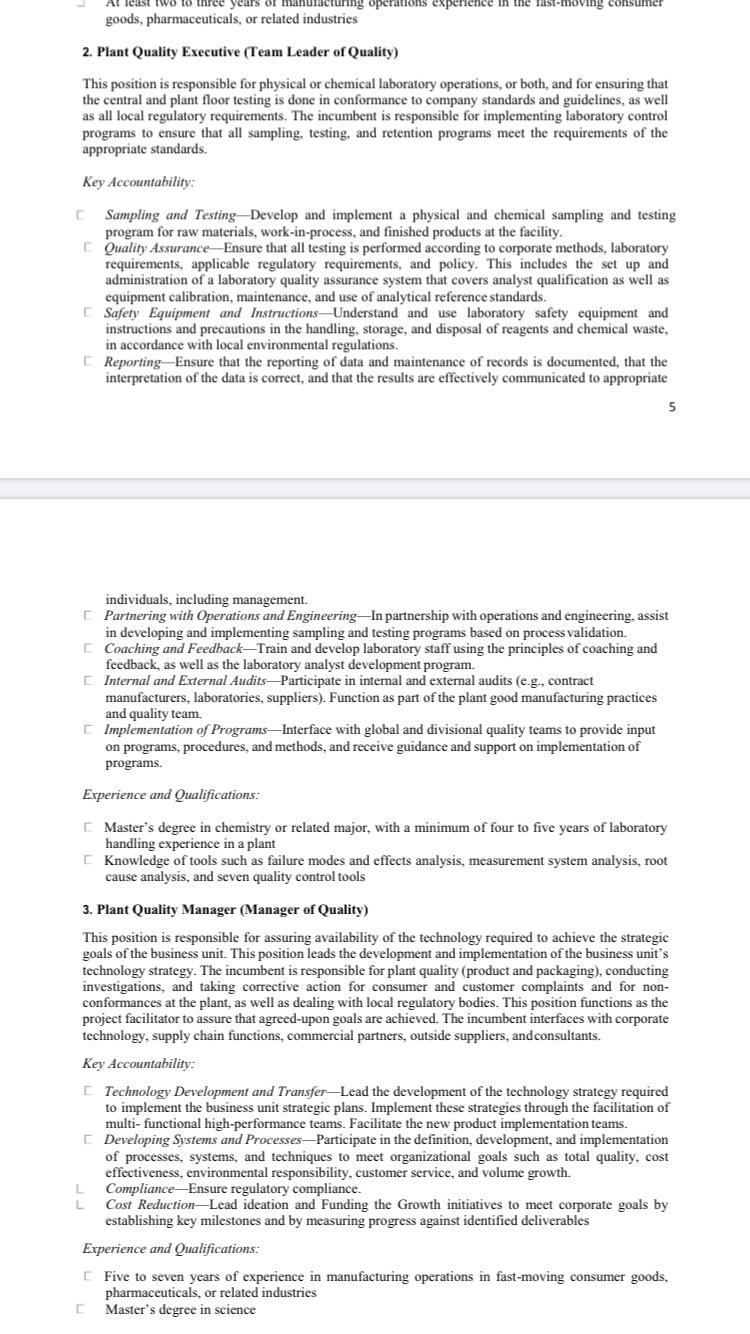

EXHIBIT 2: COLGATE-PALMOLIVE (INDIA) LIMITED, SRI CITY PLANT JOB DESCRIPTIONS 1. Shift in Charge (Team Leader) This position is responsible for effectively managing the shift production and maintenance activities for a given production area, with strong focus on plant safety and quality systems. The role involves managing the production and maintenance activities for the shift, along with managing the performance of shop floor associates. Key Accountability: Achieving Key Performance Indicators-Ensure productivity and line efficiencies. Manage people, materials, and equipment upkeep. Drive autonomous maintenance. Track and analyze variances associated with materials and finished products. People Management Execute biannual performance management process for shop floor associates. Compliances Ensure adherence to the company's policies and procedures, production processes and systems, standard operating procedures, and regulatory requirements. Cost Reduction Identify, recommend, and implement a manufacturing cost reduction program, and execute new technology in the area. Data Reporting-Record and report on all line performance issues, changeover times and downtimes, and other production matters. Experience and Qualifications: Diploma or degree in engineering (production, electrical, or mechanical) At least two to three years of manufacturing operations experience in the fast- moving consumer goods, pharmaceuticals, or related industries 2. Plant Quality Executive (Team Leader of Quality) This position is responsible for physical or chemical laboratory operations, or both, and for ensuring that the central and plant floor testing is done in conformance to company standards and guidelines, as well as all local regulatory requirements. The incumbent is responsible for implementing laboratory control programs to ensure that all sampling, testing, and retention programs meet the requirements of the appropriate standards Key Accountability: Sampling and Testing-Develop and implement a physical and chemical sampling and testing program for raw materials, work-in-process, and finished products at the facility. Quality Assurance. Ensure that all testing is performed according to corporate methods, laboratory requirements, nts, applicable regulatory requirements, and policy. This includes the set up and administration of a laboratory quality assurance system that covers analyst qualification as well as equipment calibration, maintenance, and use of analytical reference standards, Safety Equipment and Instructions Understand and use laboratory safety equipment and instructions and precautions in the handling, storage, and disposal of reagents and chemical waste, in accordance with local environmental regulations. Reporting --Ensure that the reporting of data and maintenance of records is documented, that the interpretation of the data is correct, and that the results are effectively communicated to appropriate 5 individuals, including management. [ Partnering with Operations and EngineeringIn partnership with operations and engineering, assist in developing and implementing sampling and testing programs based on process validation Coaching and Feedback-Train and develop laboratory staff using the principles of coaching and feedback, as well as the laboratory analyst development program. Internal and External Audits - Participate in internal and external audits (e.g., contract manufacturers, laboratories, suppliers). Function as part of the plant good manufacturing practices and quality team. Implementation of Programs Interface with global and divisional quality teams to provide input on programs, procedures, and methods, and receive guidance and support on implementation of programs. Fenerience and qualifications to three years anulacturing operations experience goods, pharmaceuticals, or related industries the last-moving consumer 2. Plant Quality Executive (Team Leader of Quality) This position is responsible for physical or chemical laboratory operations, or both, and for ensuring that the central and plant floor testing is done in conformance to company standards and guidelines, as well as all local regulatory requirements. The incumbent is responsible for implementing laboratory control programs to ensure that all sampling, testing, and retention programs meet the requirements of the appropriate standards. Key Accountability: Sampling and Testing - Develop and implement a physical and chemical sampling and testing program for raw materials, work-in-process, and finished products at the facility. Quality Assurance-Ensure that all testing is performed according to corporate methods, laboratory requirements, applicable regulatory requirements, and policy. This includes the set up and administration of a laboratory quality assurance system that covers analyst qualification as well as equipment ment calibration, maintenance, and use of analytical reference standards. Safety Equipment and Instructions-Understand and use laboratory safety equipment and instructions and precautions in the handling, storage, and disposal of reagents and chemical waste, in accordance with local environmental regulations. Reporting-Ensure that the reporting of data and maintenance of records is documented, that the interpretation of the data is correct, and that the results are effectively communicated to appropriate 5 individuals, including management. [Partnering with Operations and Engineering-In partnership with operations and engineering, assist in developing and implementing sampling and testing programs based on process validation. Coaching and Feedback-Train and develop laboratory staff using the principles of coaching and feedback, as well as the laboratory analyst development program. Internal and External Audits Participate in internal and external audits (e.g., contract manufacturers, laboratories, suppliers). Function as part of the plant good manufacturing practices and quality team. Implementation of Programs Interface with global and divisional quality teams to provide input on programs, procedures, and methods, and receive guidance and support on implementation of programs. Experience and Qualifications: Master's degree in chemistry or related major, with a minimum of four to five years of laboratory handling experience in a plant Knowledge of tools such as failure modes and effects analysis, measurement system analysis, root cause analysis, and seven quality control tools 3. Plant Quality Manager (Manager of Quality) This position is responsible for assuring availability of the technology required to achieve the strategic goals of the business unit. This position leads the development and implementation of the business unit's technology strategy. The incumbent is responsible for plant quality product and packaging), conducting investigations, and taking corrective action for consumer and customer complaints and for non- conformances at the plant, as well as dealing with local regulatory bodies. This position functions as the project facilitator to assure that agreed-upon goals are achieved. The incumbent interfaces with corporate technology, supply chain functions, commercial partners, outside suppliers, and consultants. Key Accountability: Technology Development and Transfer-Lead the development of the technology strategy required to implement the business unit strategic plans. Implement these strategies through the facilitation of multi-functional high-performance teams. Facilitate the new product implementation teams. Developing Systems and Processes - Participate in the definition, development, and implementation of processes, systems, and techniques to meet organizational goals such as total quality, cost effectiveness, environmental responsibility, customer service, and volume growth. ComplianceEnsure regulatory compliance. Cost Reduction Lead ideation and Funding the Growth initiatives to meet corporate goals by establishing key milestones and by measuring progress against identified deliverables Experience and Qualifications: Five to seven years of experience in manufacturing operations in fast-moving consumer goods, pharmaceuticals, or related industries Master's degree in scienceStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts