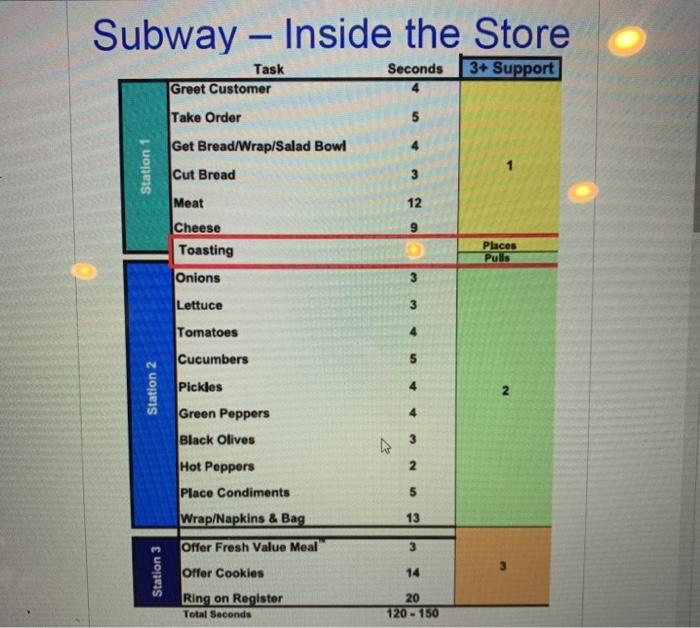

Question: Subway - Inside the Store Seconds 3+ Support Task Greet Customer Take Order 5 Get Bread/Wrap/Salad Bowl Station 1 Cut Bread 3 Meat 12 9

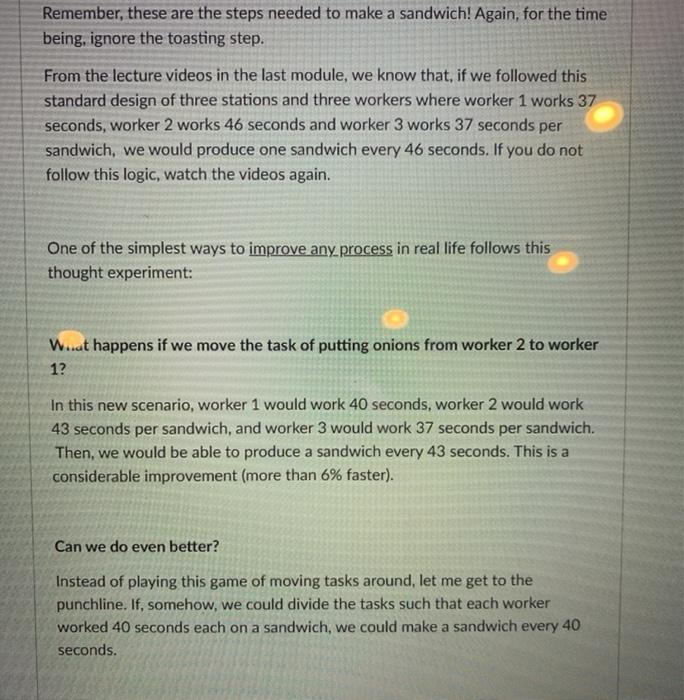

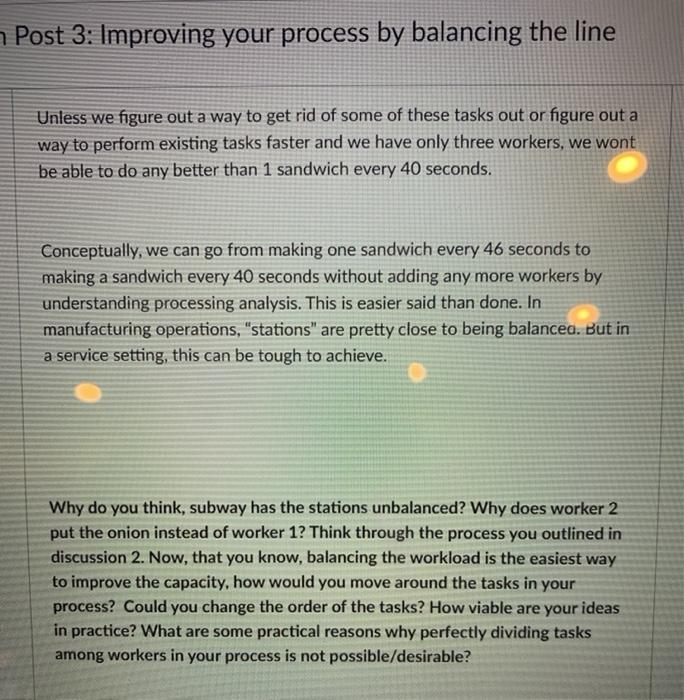

Subway - Inside the Store Seconds 3+ Support Task Greet Customer Take Order 5 Get Bread/Wrap/Salad Bowl Station 1 Cut Bread 3 Meat 12 9 Cheese Toasting Onions Places Pulls 3 Lettuce 3 Tomatoes 4 Cucumbers 5 Station 2 Pickles 4 N 4 3 Green Peppers Black Olives Hot Peppers Place Condiments Wrap/Napkins & Bag 2 5 13 Offer Fresh Value Meal 3 Station 3 14 Offer Cookies Ring on Register Total Seconds 20 120 - 150 Remember, these are the steps needed to make a sandwich! Again, for the time being, ignore the toasting step. From the lecture videos in the last module, we know that, if we followed this standard design of three stations and three workers where worker 1 works 37 seconds, worker 2 works 46 seconds and worker 3 works 37 seconds per sandwich, we would produce one sandwich every 46 seconds. If you do not follow this logic, watch the videos again. One of the simplest ways to improve any process in real life follows this thought experiment: W..at happens if we move the task of putting onions from worker 2 to worker 1? In this new scenario, worker 1 would work 40 seconds, worker 2 would work 43 seconds per sandwich, and worker 3 would work 37 seconds per sandwich. Then, we would be able to produce a sandwich every 43 seconds. This is a considerable improvement (more than 6% faster) Can we do even better? Instead of playing this game of moving tasks around, let me get to the punchline. If, somehow, we could divide the tasks such that each worker worked 40 seconds each on a sandwich, we could make a sandwich every 40 seconds. Post 3: Improving your process by balancing the line Unless we figure out a way to get rid of some of these tasks out or figure out a way to perform existing tasks faster and we have only three workers, we wont be able to do any better than 1 sandwich every 40 seconds. Conceptually, we can go from making one sandwich every 46 seconds to making a sandwich every 40 seconds without adding any more workers by understanding processing analysis. This is easier said than done. In manufacturing operations, "stations" are pretty close to being balanced. But in a service setting, this can be tough to achieve. Why do you think, subway has the stations unbalanced? Why does worker 2 put the onion instead of worker 1? Think through the process you outlined in discussion 2. Now, that you know, balancing the workload is the easiest way to improve the capacity, how would you move around the tasks in your process? Could you change the order of the tasks? How viable are your ideas in practice? What are some practical reasons why perfectly dividing tasks among workers in your process is not possible/desirable? Subway - Inside the Store Seconds 3+ Support Task Greet Customer Take Order 5 Get Bread/Wrap/Salad Bowl Station 1 Cut Bread 3 Meat 12 9 Cheese Toasting Onions Places Pulls 3 Lettuce 3 Tomatoes 4 Cucumbers 5 Station 2 Pickles 4 N 4 3 Green Peppers Black Olives Hot Peppers Place Condiments Wrap/Napkins & Bag 2 5 13 Offer Fresh Value Meal 3 Station 3 14 Offer Cookies Ring on Register Total Seconds 20 120 - 150 Remember, these are the steps needed to make a sandwich! Again, for the time being, ignore the toasting step. From the lecture videos in the last module, we know that, if we followed this standard design of three stations and three workers where worker 1 works 37 seconds, worker 2 works 46 seconds and worker 3 works 37 seconds per sandwich, we would produce one sandwich every 46 seconds. If you do not follow this logic, watch the videos again. One of the simplest ways to improve any process in real life follows this thought experiment: W..at happens if we move the task of putting onions from worker 2 to worker 1? In this new scenario, worker 1 would work 40 seconds, worker 2 would work 43 seconds per sandwich, and worker 3 would work 37 seconds per sandwich. Then, we would be able to produce a sandwich every 43 seconds. This is a considerable improvement (more than 6% faster) Can we do even better? Instead of playing this game of moving tasks around, let me get to the punchline. If, somehow, we could divide the tasks such that each worker worked 40 seconds each on a sandwich, we could make a sandwich every 40 seconds. Post 3: Improving your process by balancing the line Unless we figure out a way to get rid of some of these tasks out or figure out a way to perform existing tasks faster and we have only three workers, we wont be able to do any better than 1 sandwich every 40 seconds. Conceptually, we can go from making one sandwich every 46 seconds to making a sandwich every 40 seconds without adding any more workers by understanding processing analysis. This is easier said than done. In manufacturing operations, "stations" are pretty close to being balanced. But in a service setting, this can be tough to achieve. Why do you think, subway has the stations unbalanced? Why does worker 2 put the onion instead of worker 1? Think through the process you outlined in discussion 2. Now, that you know, balancing the workload is the easiest way to improve the capacity, how would you move around the tasks in your process? Could you change the order of the tasks? How viable are your ideas in practice? What are some practical reasons why perfectly dividing tasks among workers in your process is not possible/desirable