Question: Summary: Lean Systems 1 3 . Anguilla Manufacturing is interested in using the data collected during value stream mapping to evaluate the current state performance

Summary: Lean Systems

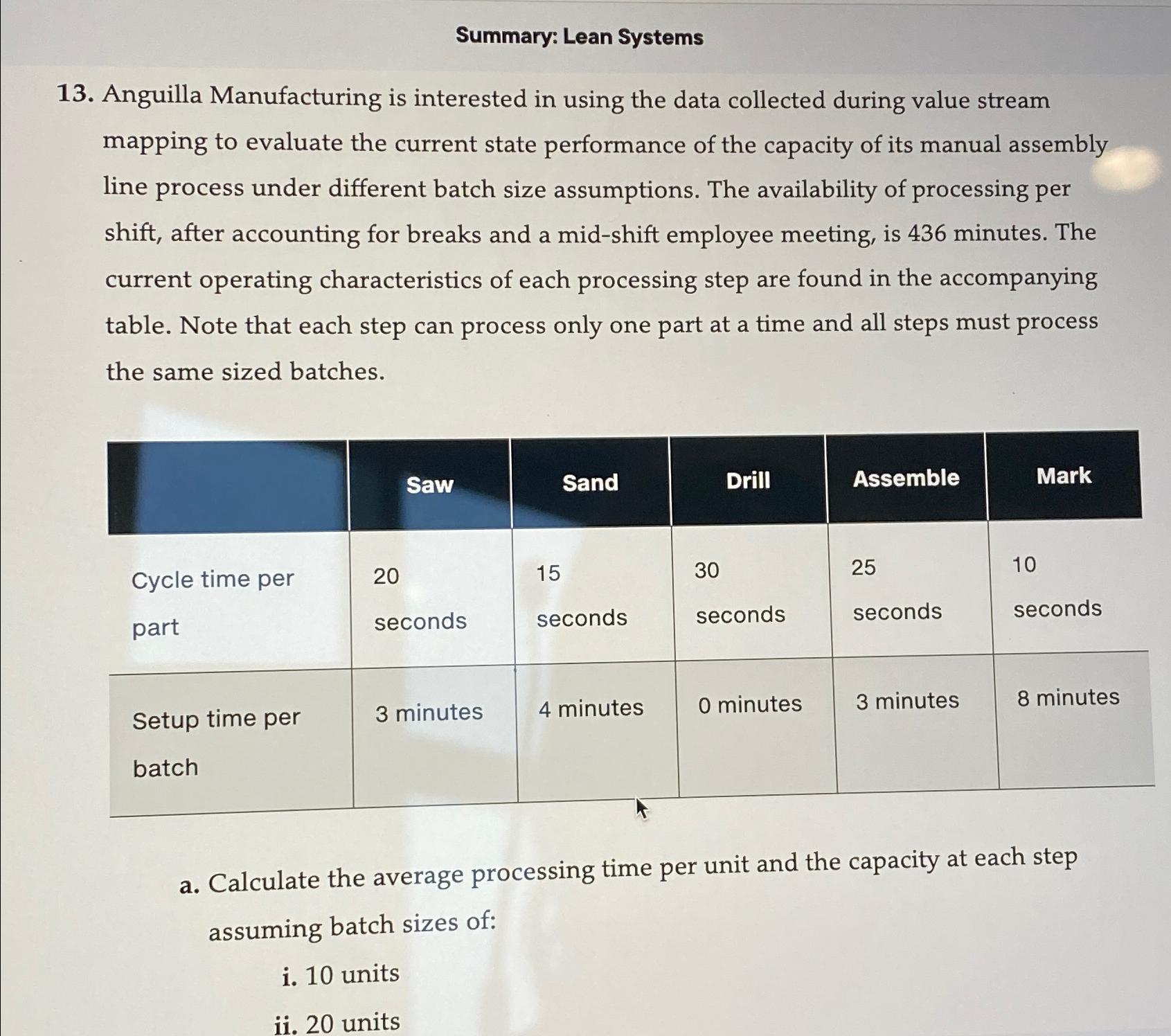

Anguilla Manufacturing is interested in using the data collected during value stream mapping to evaluate the current state performance of the capacity of its manual assembly line process under different batch size assumptions. The availability of processing per shift, after accounting for breaks and a midshift employee meeting, is minutes. The current operating characteristics of each processing step are found in the accompanying table. Note that each step can process only one part at a time and all steps must process the same sized batches.

tableSaw,Sand,Drill,Assemble,MarktableCycle time perparttablesecondstablesecondstablesecondstablesecondstablesecondstableSetup time perbatch minutes, minutes, minutes, minutes, minutes

a Calculate the average processing time per unit and the capacity at each step assuming batch sizes of:

i units

ii units

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock