Question: Supply chain management 1. David has its engine assembly plant in Seoul and its motorcycle assembly plant in Busan. Engines are transported between the two

Supply chain management

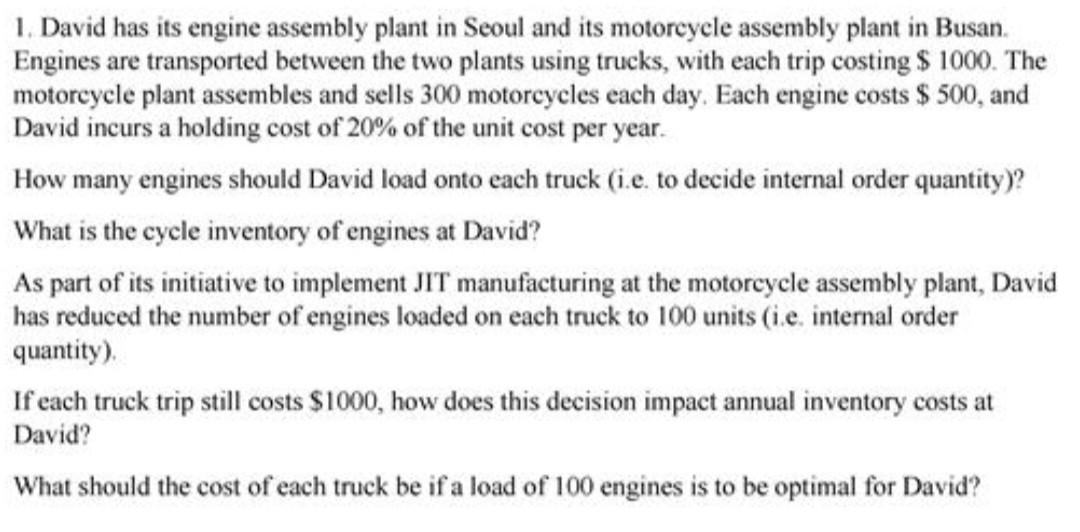

1. David has its engine assembly plant in Seoul and its motorcycle assembly plant in Busan. Engines are transported between the two plants using trucks, with each trip costing $1000. The motorcycle plant assembles and sells 300 motorcycles each day. Each engine costs $500, and David incurs a holding cost of 20% of the unit cost per year. How many engines should David load onto each truck (i.e. to decide internal order quantity)? What is the cycle inventory of engines at David? As part of its initiative to implement JIT manufacturing at the motorcycle assembly plant, David has reduced the number of engines loaded on each truck to 100 units (i.e. internal order quantity). If each truck trip still costs $1000, how does this decision impact annual inventory costs at David? What should the cost of each truck be if a load of 100 engines is to be optimal for DavidStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock