Question: Supply Chain Management S&OP Process problem Exercise for S&OP The Fruity Beverage Company produces a popular juice family known as Vitamin-packed. Its sales are somewhat

Supply Chain Management S&OP Process problem

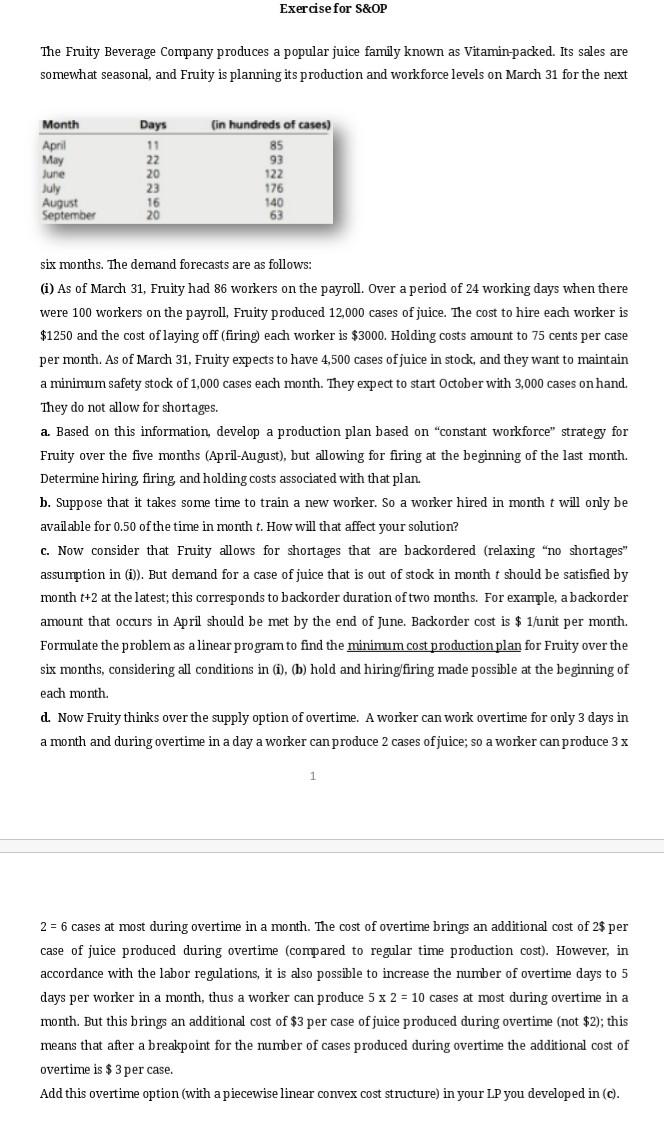

Exercise for S&OP The Fruity Beverage Company produces a popular juice family known as Vitamin-packed. Its sales are somewhat seasonal, and Fruity is planning its production and workforce levels on March 31 for the next Month Days (in hundreds of cases) April May June July August September 11 22 20 23 16 20 85 93 122 176 140 63 six months. The demand forecasts are as follows: (i) As of March 31, Fruity had 86 workers on the payroll. Over a period of 24 working days when there were 100 workers on the payroll, Fruity produced 12,000 cases of juice. The cost to hire each worker is $1250 and the cost of laying off (firing each worker is $3000. Holding costs amount to 75 cents per case per month. As of March 31, Fruity expects to have 4,500 cases of juice in stock, and they want to maintain a minimum safety stock of 1,000 cases each month. They expect to start October with 3,000 cases on hand. They do not allow for shortages. a. Based on this information, develop a production plan based on constant workforce" strategy for Fruity over the five months (April-August), but allowing for firing at the beginning of the last month. Determine hiring firing and holding costs associated with that plan. b. Suppose that it takes some time to train a new worker. So a worker hired in month t will only be available for 0.50 of the time in month t. How will that affect your solution? C. Now consider that Fruity allows for shortages that are backordered (relaxing "no shortages" assumption in (i)). But demand for a case of juice that is out of stock in month t should be satisfied by month t+2 at the latest; this corresponds to backorder duration of two months. For example, a backorder amount that occurs in April should be met by the end of June. Backorder cost is $ 1/unit per month. Formulate the problem as a linear program to find the minimum cost production plan for Fruity over the six months, considering all conditions in (i), (b) hold and hiring firing made possible at the beginning of each month. d. Now Fruity thinks over the supply option of overtime. A worker can work overtime for only 3 days in a month and during overtime in a day a worker can produce 2 cases of juice; so a worker can produce 3 x 2 - 6 cases at most during overtime in a month. The cost of overtime brings an additional cost of 2$ per case of juice produced during overtime (compared to regular time production cost). However, in accordance with the labor regulations, it is also possible to increase the number of overtime days to 5 days per worker in a month, thus worker can produce 5 x 2 = 10 cases at most during overtime in a month. But this brings an additional cost of $3 per case of juice produced during overtime (not $2); this means that after a breakpoint for the number of cases produced during overtime the additional cost of overtime is $ 3 per case. Add this overtime option (with a piecewise linear convex cost structure) in your LP you developed in (c)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock