Question: systems simulation class Help please show what i need to use please A proposed production system consists of five serial automatic workstations. The processing times

systems simulation class

Help please

show what i need to use please

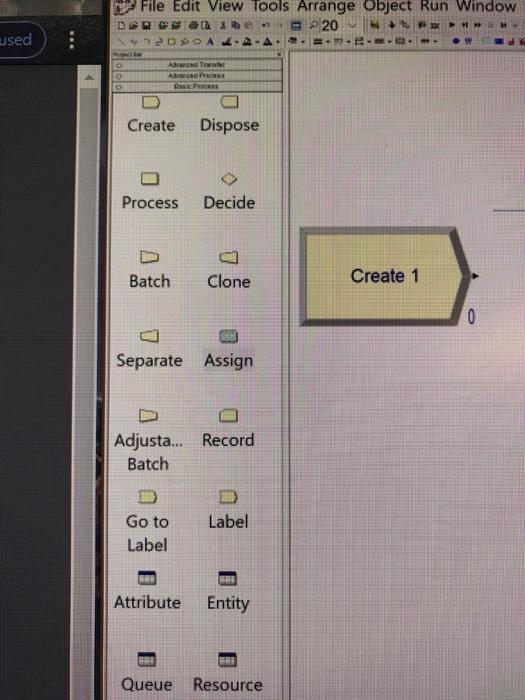

A proposed production system consists of five serial automatic workstations. The processing times at workstations are constant: 11, 10, 11, 11, and 12 (all times given in this problem are in minutes). The part interatrial times are UNIF(13,15). There is an unlimited buffer in front of all workstations, and we will assume that all transfer times are negligible or zero. The unique aspect of this system is that at workstations 2 through 5 there is a chance that the part will need to be reprocessed by the workstations that precedes it. For example, after completion at workstation 2, the part can be sent back to the queue in front of workstation 1. The probability of revisiting a workstation is independent in that the same part could be sent back many times with no change in the probability. At present, it is estimated that this probability, the same for all four workstations, will be between 5 % and 10 %. Develop the simulation model and make six runs of 10,000 minutes each for probabilities of 5,6,7,8,9, and 10%. Consider first 500 minutes as warm-up period. Using excel, construct a plot of the average cycle time (system time) against the probability of a revisit. Also include the maximum cycle time for each run on your plot. Run the model for 5 replications and compare the results. BAJA_RULES_202 ingy File Edit View Tools Arrange Object Run Window DORCE 22 20 HXH DOA- - used Add to AGA Create Dispose Process Decide Batch Clone Create 1 0 Separate Assign D Adjusta. Record Batch Label Go to Label Attribute Entity Queue Resource Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock