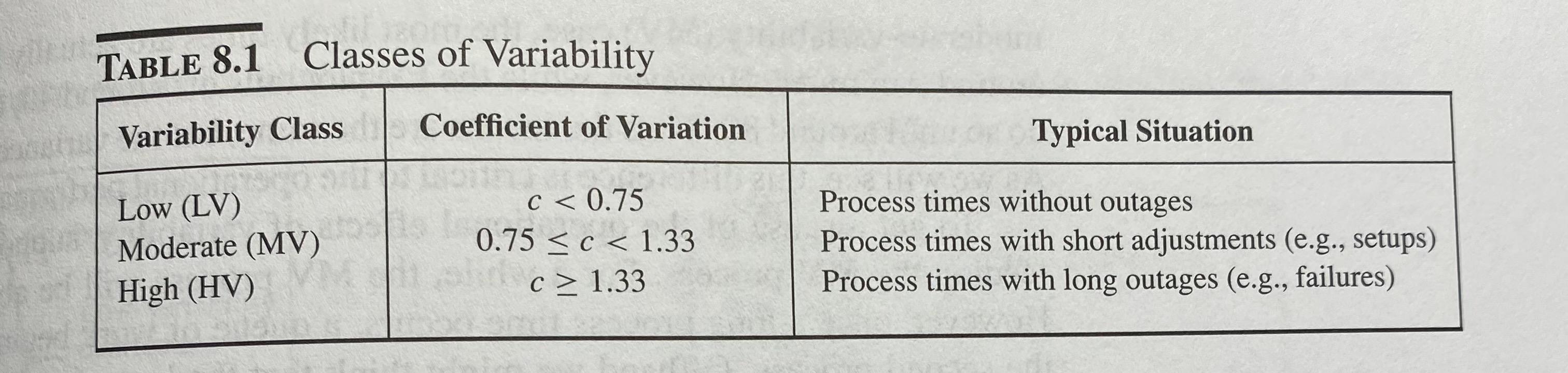

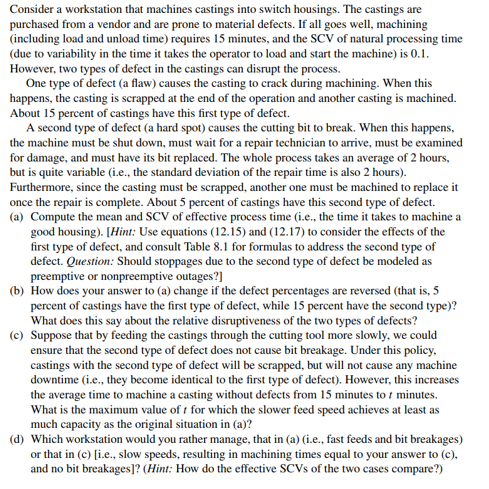

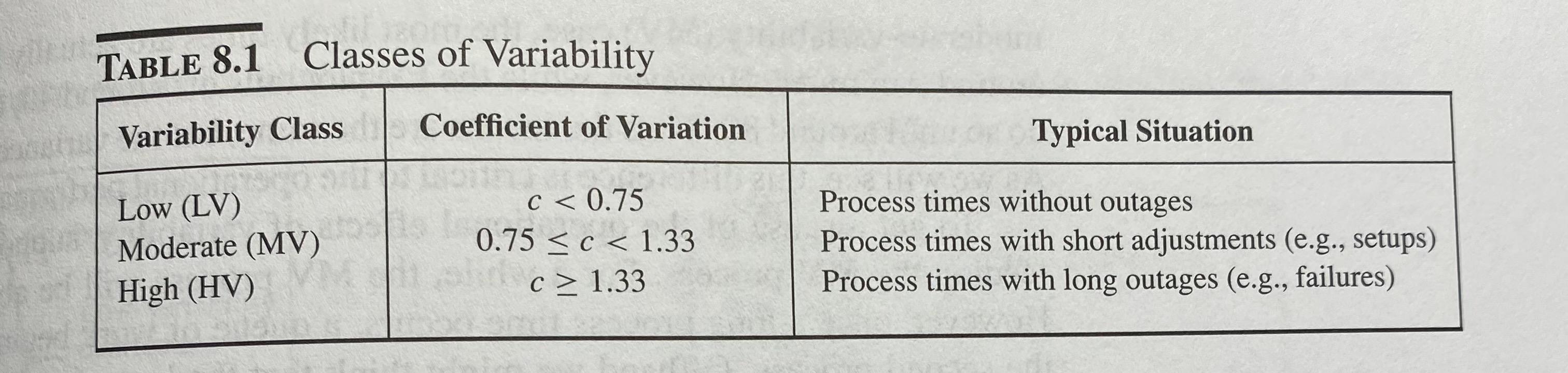

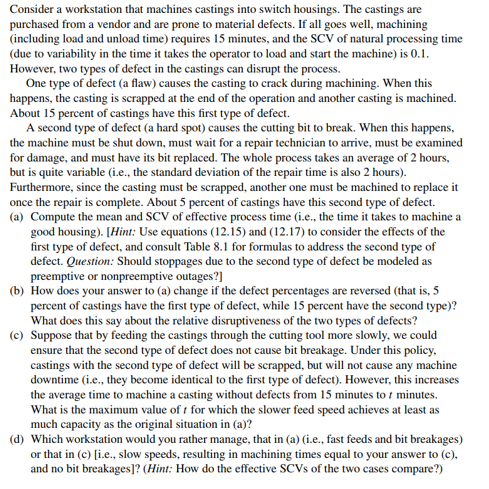

Question: TABLE 8.1 Classes of Variability Variability Class Coefficient of Variation Typical Situation Low (LV) Moderate (MV) High (HV) C 1.33 Process times without outages Process

TABLE 8.1 Classes of Variability Variability Class Coefficient of Variation Typical Situation Low (LV) Moderate (MV) High (HV) C 1.33 Process times without outages Process times with short adjustments (e.g., setups) Process times with long outages (e.g., failures) Consider a workstation that machines castings into switch housings. The castings are purchased from a vendor and are prone to material defects. If all goes well, machining (including load and unload time) requires 15 minutes, and the SCV of natural processing time (due to variability in the time it takes the operator to load and start the machine) is 0.1. However, two types of defect in the castings can disrupt the process. One type of defect (a flaw) causes the casting to crack during machining. When this happens, the casting is scrapped at the end of the operation and another casting is machined. About 15 percent of castings have this first type of defect. A second type of defect (a hard spot) causes the cutting bit to break. When this happens, the machine must be shut down, must wait for a repair technician to arrive, must be examined for damage, and must have its bit replaced. The whole process takes an average of 2 hours, but is quite variable (i.e., the standard deviation of the repair time is also 2 hours). Furthermore, since the casting must be scrapped, another one must be machined to replace it once the repair is complete. About 5 percent of castings have this second type of defect. (a) Compute the mean and SCV of effective process time (i.e., the time it takes to machine a good housing). [Hint: Use equations (12.15) and (12.17) to consider the effects of the first type of defect, and consult Table 8.1 for formulas to address the second type of defect. Question: Should stoppages due to the second type of defect be modeled as preemptive or nonpreemptive outages?) (b) How does your answer to (a) change if the defect percentages are reversed (that is, 5 percent of castings have the first type of defect, while 15 percent have the second type)? What does this say about the relative disruptiveness of the two types of defects? (C) Suppose that by feeding the castings through the cutting tool more slowly, we could ensure that the second type of defect does not cause bit breakage. Under this policy, castings with the second type of defect will be scrapped, but will not cause any machine downtime (i.e., they become identical to the first type of defect). However, this increases the average time to machine a casting without defects from 15 minutes to minutes. What is the maximum value of t for which the slower feed speed achieves at least as much capacity as the original situation in (a)? (d) Which workstation would you rather manage, that in (a) (i.e., fast feeds and bit breakages) or that in (c) [i.e., slow speeds, resulting in machining times equal to your answer to (c), and no bit breakages)? (Hint: How do the effective SCVs of the two cases compare?) TABLE 8.1 Classes of Variability Variability Class Coefficient of Variation Typical Situation Low (LV) Moderate (MV) High (HV) C 1.33 Process times without outages Process times with short adjustments (e.g., setups) Process times with long outages (e.g., failures) Consider a workstation that machines castings into switch housings. The castings are purchased from a vendor and are prone to material defects. If all goes well, machining (including load and unload time) requires 15 minutes, and the SCV of natural processing time (due to variability in the time it takes the operator to load and start the machine) is 0.1. However, two types of defect in the castings can disrupt the process. One type of defect (a flaw) causes the casting to crack during machining. When this happens, the casting is scrapped at the end of the operation and another casting is machined. About 15 percent of castings have this first type of defect. A second type of defect (a hard spot) causes the cutting bit to break. When this happens, the machine must be shut down, must wait for a repair technician to arrive, must be examined for damage, and must have its bit replaced. The whole process takes an average of 2 hours, but is quite variable (i.e., the standard deviation of the repair time is also 2 hours). Furthermore, since the casting must be scrapped, another one must be machined to replace it once the repair is complete. About 5 percent of castings have this second type of defect. (a) Compute the mean and SCV of effective process time (i.e., the time it takes to machine a good housing). [Hint: Use equations (12.15) and (12.17) to consider the effects of the first type of defect, and consult Table 8.1 for formulas to address the second type of defect. Question: Should stoppages due to the second type of defect be modeled as preemptive or nonpreemptive outages?) (b) How does your answer to (a) change if the defect percentages are reversed (that is, 5 percent of castings have the first type of defect, while 15 percent have the second type)? What does this say about the relative disruptiveness of the two types of defects? (C) Suppose that by feeding the castings through the cutting tool more slowly, we could ensure that the second type of defect does not cause bit breakage. Under this policy, castings with the second type of defect will be scrapped, but will not cause any machine downtime (i.e., they become identical to the first type of defect). However, this increases the average time to machine a casting without defects from 15 minutes to minutes. What is the maximum value of t for which the slower feed speed achieves at least as much capacity as the original situation in (a)? (d) Which workstation would you rather manage, that in (a) (i.e., fast feeds and bit breakages) or that in (c) [i.e., slow speeds, resulting in machining times equal to your answer to (c), and no bit breakages)? (Hint: How do the effective SCVs of the two cases compare?)