Question: table q2a: table 5 table q2b: table 6 table q2c: table 7 a) Gasing Sdn Bhd manufacturer of sandals has developed a monthly forecast for

table q2a: table 5 table q2b: table 6 table q2c: table 7

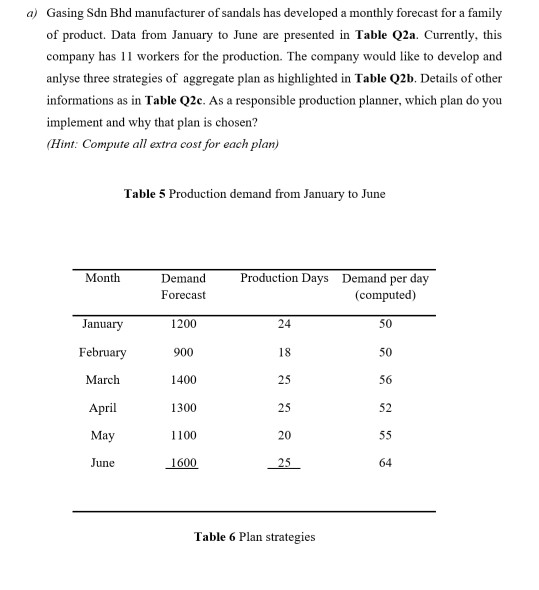

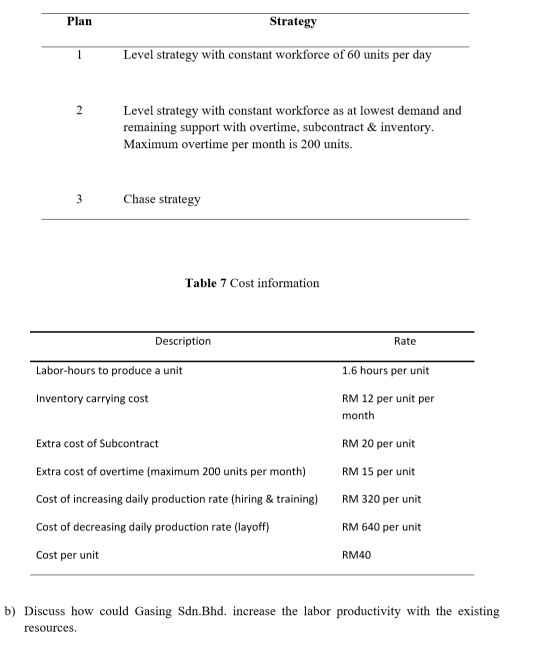

a) Gasing Sdn Bhd manufacturer of sandals has developed a monthly forecast for a family of product. Data from January to June are presented in Table Q2a. Currently, this company has 11 workers for the production. The company would like to develop and anlyse three strategies of aggregate plan as highlighted in Table Q2b. Details of other informations as in Table Q2c. As a responsible production planner, which plan do you implement and why that plan is chosen? (Hint: Compute all extra cost for each plan) Table 5 Production demand from January to June Month Demand Forecast Production Days Demand per day (computed) January 1200 24 50 February 900 18 50 March 1400 25 56 April 1300 25 52 May 1100 20 55 June 1600 25 64 Table 6 Plan strategies Plan Strategy 1 Level strategy with constant workforce of 60 units per day 2 Level strategy with constant workforce as at lowest demand and remaining support with overtime, subcontract & inventory. Maximum overtime per month is 200 units. 3 Chase strategy Table 7 Cost information Description Rate Labor-hours to produce a unit Inventory carrying cost Extra cost of Subcontract Extra cost of overtime (maximum 200 units per month) Cost of increasing daily production rate (hiring & training) Cost of decreasing daily production rate (layoff) Cost per unit 1.6 hours per unit RM 12 per unit per month RM 20 per unit RM 15 per unit RM 320 per unit RM 640 per unit RM40 b) Discuss how could Gasing Sdn.Bhd. increase the labor productivity with the existing resources, a) Gasing Sdn Bhd manufacturer of sandals has developed a monthly forecast for a family of product. Data from January to June are presented in Table Q2a. Currently, this company has 11 workers for the production. The company would like to develop and anlyse three strategies of aggregate plan as highlighted in Table Q2b. Details of other informations as in Table Q2c. As a responsible production planner, which plan do you implement and why that plan is chosen? (Hint: Compute all extra cost for each plan) Table 5 Production demand from January to June Month Demand Forecast Production Days Demand per day (computed) January 1200 24 50 February 900 18 50 March 1400 25 56 April 1300 25 52 May 1100 20 55 June 1600 25 64 Table 6 Plan strategies Plan Strategy 1 Level strategy with constant workforce of 60 units per day 2 Level strategy with constant workforce as at lowest demand and remaining support with overtime, subcontract & inventory. Maximum overtime per month is 200 units. 3 Chase strategy Table 7 Cost information Description Rate Labor-hours to produce a unit Inventory carrying cost Extra cost of Subcontract Extra cost of overtime (maximum 200 units per month) Cost of increasing daily production rate (hiring & training) Cost of decreasing daily production rate (layoff) Cost per unit 1.6 hours per unit RM 12 per unit per month RM 20 per unit RM 15 per unit RM 320 per unit RM 640 per unit RM40 b) Discuss how could Gasing Sdn.Bhd. increase the labor productivity with the existing resourcesStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock