Question: Can anyone help me on this question pls. Menara Sdn Bhd manufacturer of shoes has developed a monthly forecast for a family product. Data from

Can anyone help me on this question pls.

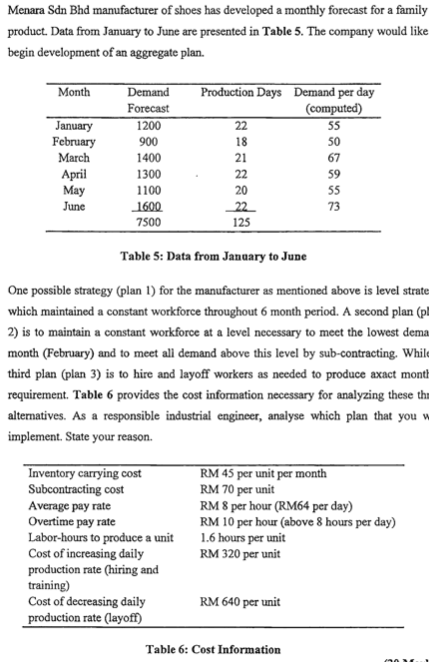

Menara Sdn Bhd manufacturer of shoes has developed a monthly forecast for a family product. Data from January to June are presented in Table 5. The company would like begin development of an aggregate plan. Month January February March April May June Demand Forecast 1200 900 1400 1300 1100 1600 7500 Production Days Demand per day (computed) 22 55 18 50 21 67 22 59 20 S5 22 73 125 Table 5: Data from January to June One possible strategy (plan 1) for the manufacturer as mentioned above is level strate which maintained a constant workforce throughout 6 month period. A second plan (p 2) is to maintain a constant workforce at a level necessary to meet the lowest dema month (February) and to meet all demand above this level by sub-contracting. While third plan (plan 3) is to hire and layoff workers as needed to produce axact month requirement. Table 6 provides the cost information necessary for analyzing these thi alternatives. As a responsible industrial engineer, analyse which plan that you implement. State your reason. Inventory carrying cost Subcontracting cost Average pay rate Overtime pay rate Labor-hours to produce a unit Cost of increasing daily production rate (hiring and training) Cost of decreasing daily production rate (layoff) RM 45 per unit per month RM 70 per unit RM 8 per hour (RM64 per day) RM 10 per hour (above 8 hours per day) 1.6 hours per unit RM 320 per unit RM 640 per unit Table 6: Cost Information Menara Sdn Bhd manufacturer of shoes has developed a monthly forecast for a family product. Data from January to June are presented in Table 5. The company would like begin development of an aggregate plan. Month January February March April May June Demand Forecast 1200 900 1400 1300 1100 1600 7500 Production Days Demand per day (computed) 22 55 18 50 21 67 22 59 20 S5 22 73 125 Table 5: Data from January to June One possible strategy (plan 1) for the manufacturer as mentioned above is level strate which maintained a constant workforce throughout 6 month period. A second plan (p 2) is to maintain a constant workforce at a level necessary to meet the lowest dema month (February) and to meet all demand above this level by sub-contracting. While third plan (plan 3) is to hire and layoff workers as needed to produce axact month requirement. Table 6 provides the cost information necessary for analyzing these thi alternatives. As a responsible industrial engineer, analyse which plan that you implement. State your reason. Inventory carrying cost Subcontracting cost Average pay rate Overtime pay rate Labor-hours to produce a unit Cost of increasing daily production rate (hiring and training) Cost of decreasing daily production rate (layoff) RM 45 per unit per month RM 70 per unit RM 8 per hour (RM64 per day) RM 10 per hour (above 8 hours per day) 1.6 hours per unit RM 320 per unit RM 640 per unit Table 6: Cost InformationStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock