Question: Task: You manage the production process in the high - tech facility of Dale Computers Inc. The facility consists of three different assembly lines (

Task:

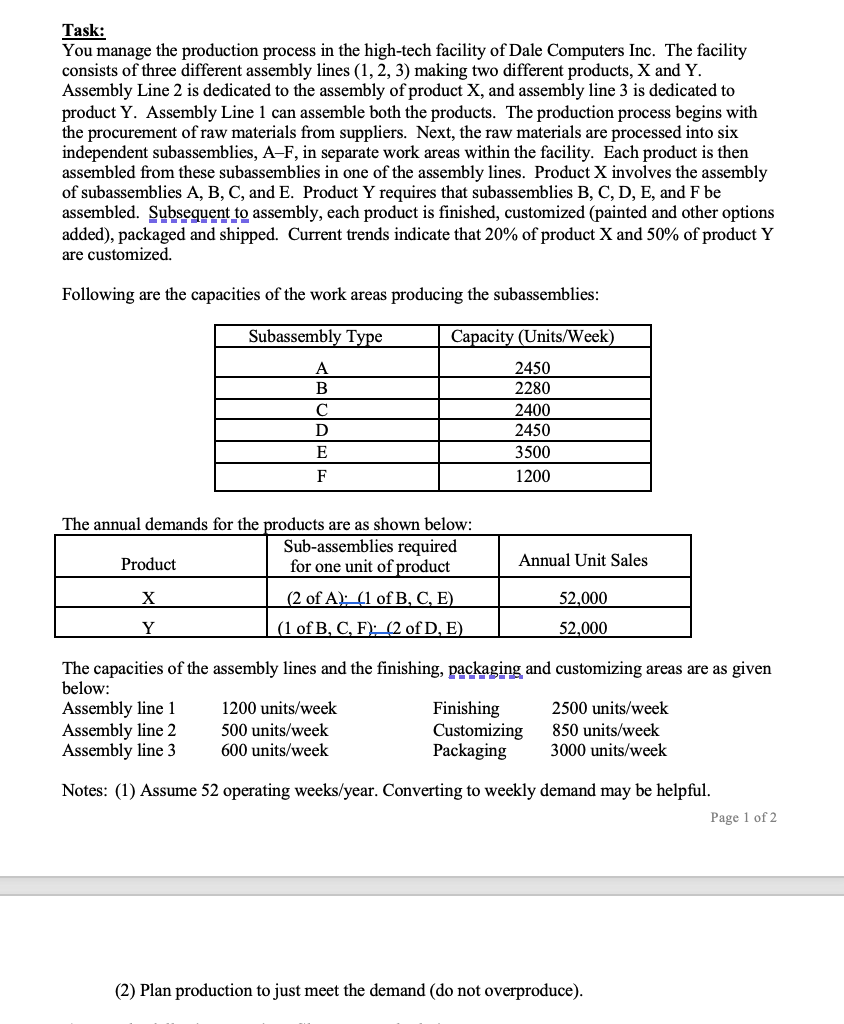

You manage the production process in the hightech facility of Dale Computers Inc. The facility consists of three different assembly lines making two different products, X and Y Assembly Line is dedicated to the assembly of product X and assembly line is dedicated to product Y Assembly Line can assemble both the products. The production process begins with the procurement of raw materials from suppliers. Next, the raw materials are processed into six independent subassemblies, AF in separate work areas within the facility. Each product is then assembled from these subassemblies in one of the assembly lines. Product X involves the assembly of subassemblies A B C and E Product Y requires that subassemblies B C D E and F be assembled. Subsequent to assembly, each product is finished, customized painted and other options added packaged and shipped. Current trends indicate that of product X and of product Y are customized.

Following are the capacities of the work areas producing the subassemblies:

Subassembly Type Capacity UnitsWeek

A

B

C

D

E

F

The annual demands for the products are as shown below:

Product Subassemblies required for one unit of product Annual Unit Sales

X of A; of B C E

Y of B C F; of D E

The capacities of the assembly lines and the finishing, packaging and customizing areas are as given below:

Assembly line unitsweek Finishing unitsweek

Assembly line unitsweek Customizing unitsweek

Assembly line unitsweek Packaging unitsweek

Notes: Assume operating weeksyear Converting to weekly demand may be helpful.

Plan production to just meet the demand do not overproduce

Answer the following questions Show your calculations.

From the point of view of capacity management, what is the key business issue for Dale Computers, given that demand forecast is available? Note: Answer this in concept, before you do Part below

With the current weekly demands of for each product X and Y what is the current bottleneck resource? Show your calculations. Note: Dont change demand yet

Management must deal with changing demand and resource constraint, by analyzing alternative business scenarios. If the weekly demand for X and Y increased proportionately by same percentage identify the top three resources that are bottleneck candidates. Show your calculations. Note: Take Assembly Lines together as a single resource

Now, if demands for X and Y change disproportionately by different percentage in the above situation, what does your analysis tell you about its effect on bottleneck shift, especially in product mix situation of a multiple product plant? Defend your answer with necessary whatif examples. Note: this part will assess your critical thinking

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock