Question: Tests on a small-scale tank, 0.3 m in diameter, fitted with a disc turbine of diameter 0.1 m have shown that a blending process between

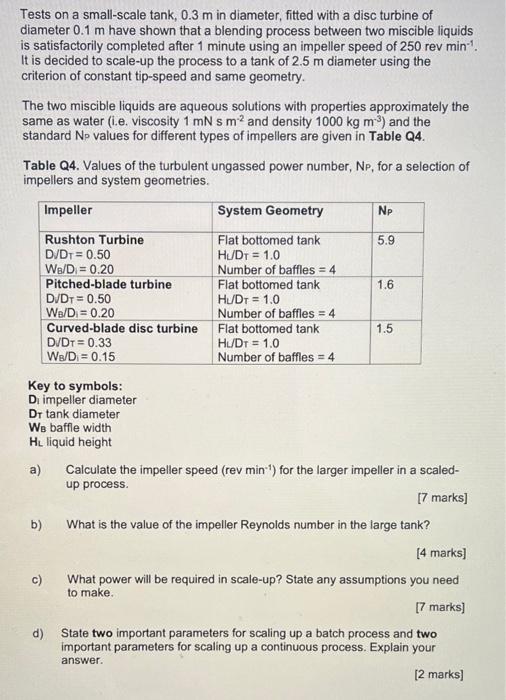

Tests on a small-scale tank, 0.3 m in diameter, fitted with a disc turbine of diameter 0.1 m have shown that a blending process between two miscible liquids is satisfactorily completed after 1 minute using an impeller speed of 250 rev min-1. It is decided to scale-up the process to a tank of 2.5 m diameter using the criterion of constant tip-speed and same geometry. The two miscible liquids are aqueous solutions with properties approximately the same as water (i.e. viscosity 1 mN s mand density 1000 kg m) and the standard NP values for different types of impellers are given in Table Q4. Table Q4. Values of the turbulent ungassed power number, Np, for a selection of impellers and system geometries. Impeller System Geometry NP 5.9 1.6 Rushton Turbine D/DT= 0.50 We/D = 0.20 Pitched-blade turbine D/DT = 0.50 We/D = 0.20 Curved-blade disc turbine D/DT= 0.33 We/D = 0.15 Flat bottomed tank HJDT = 1.0 Number of baffles = 4 Flat bottomed tank HU/D1 = 1.0 Number of baffles = 4 Flat bottomed tank H/DT = 1.0 Number of baffles = 4 1.5 Key to symbols: Di impeller diameter Dr tank diameter We baffle width HL liquid height a) Calculate the impeller speed (rev min-") for the larger impeller in a scaled- up process. [7 marks) b) What is the value of the impeller Reynolds number in the large tank? [4 marks] c) What power will be required in scale-up? State any assumptions you need to make [7 marks] d) State two important parameters for scaling up a batch process and two important parameters for scaling up a continuous process. Explain your [2 marks]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts