Question: Texas Instruments is preparing to introduce two new calculators: one for the business market called the Financial Manager and one for the engineering market called

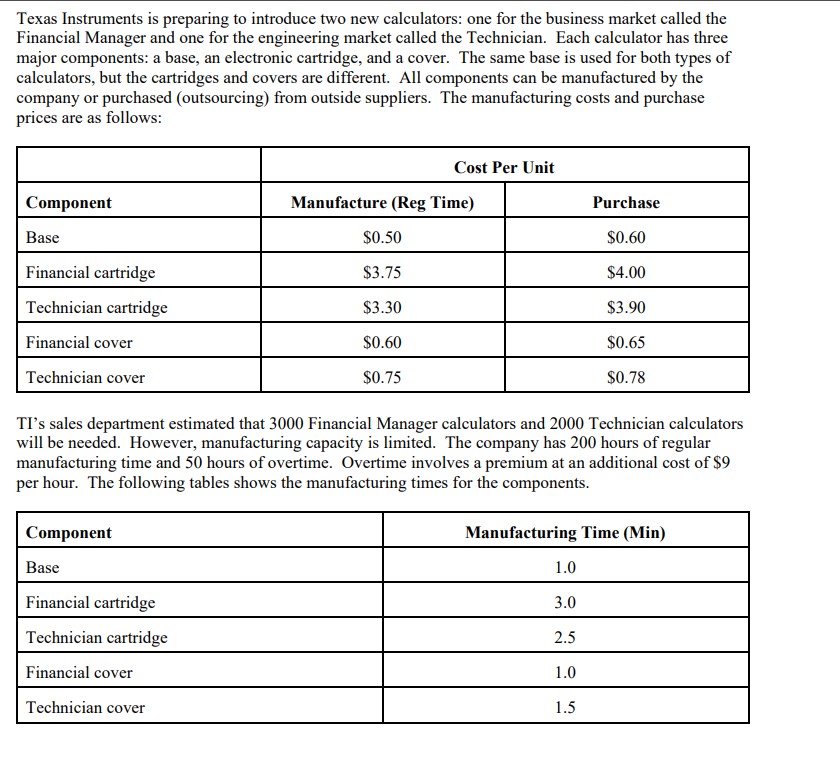

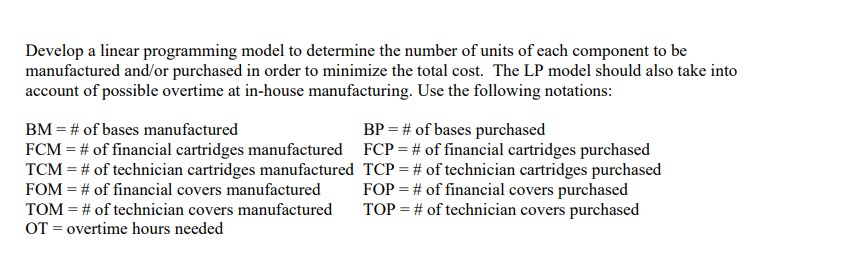

Texas Instruments is preparing to introduce two new calculators: one for the business market called the Financial Manager and one for the engineering market called the Technician. Each calculator has three major components: a base, an electronic cartridge, and a cover. The same base is used for both types of calculators, but the cartridges and covers are different. All components can be manufactured by the company or purchased (outsourcing) from outside suppliers. The manufacturing costs and purchase prices are as follows: TI's sales department estimated that 3000 Financial Manager calculators and 2000 Technician calculators will be needed. However, manufacturing capacity is limited. The company has 200 hours of regular manufacturing time and 50 hours of overtime. Overtime involves a premium at an additional cost of $9 per hour. The following tables shows the manufacturing times for the components. Develop a linear programming model to determine the number of units of each component to be manufactured and/or purchased in order to minimize the total cost. The LP model should also take into account of possible overtime at in-house manufacturing. Use the following notations: BM=#ofbasesmanufacturedFCM=#offinancialcartridgesmanufacturedTCM=#oftechniciancartridgesmanufacturedFOM=#offinancialcoversmanufacturedTOM=#oftechniciancoversmanufacturedOT=overtimehoursneededBP=#ofbasespurchasedFCP=#offinancialcartridgespurchasedTCP=#oftechniciancartridgespurchasedFOP=#offinancialcoverspurchasedTOP=#oftechniciancoverspurchased

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts