Question: thank you! We have a process; the process is represented by the process flow map shown below. The process is used to make two products,

thank you!

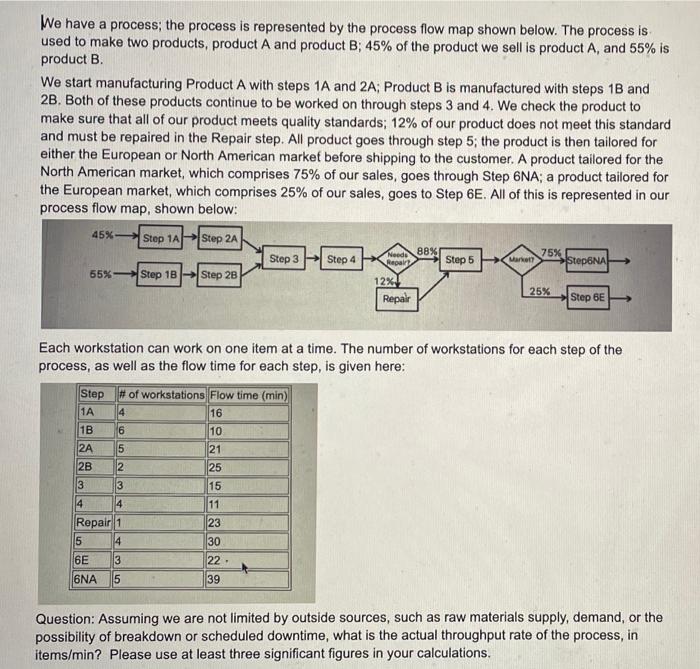

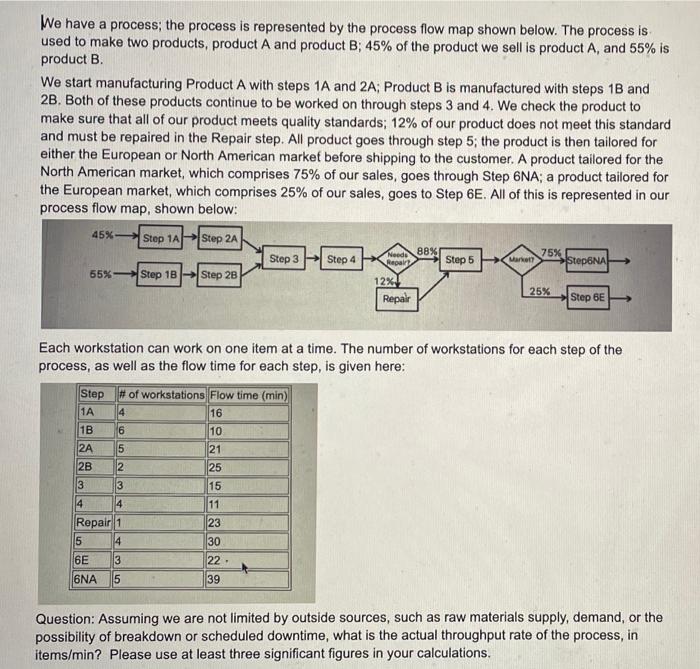

We have a process; the process is represented by the process flow map shown below. The process is used to make two products, product A and product B; 45% of the product we sell is product A, and 55% is product B. We start manufacturing Product A with steps 1A and 2A; Product B is manufactured with steps 1B and 2B. Both of these products continue to be worked on through steps 3 and 4. We check the product to make sure that all of our product meets quality standards; 12% of our product does not meet this standard and must be repaired in the Repair step. All product goes through step 5; the product is then tailored for either the European or North American market before shipping to the customer. A product tailored for the North American market, which comprises 75% of our sales, goes through Step 6NA; a product tailored for the European market, which comprises 25% of our sales, goes to Step 6E. All of this is represented in our process flow map, shown below: 45% Step 1A Step 2A 88% 75% Step 3 Step 4 Needs Repair Step 5 Market? Step6NA 55%-Step 1B-Step 28 12% Repair 25% Step 6E Each workstation can work on one item at a time. The number of workstations for each step of the process, as well as the flow time for each step, is given here: Step # of workstations Flow time (min) 1A 4 16 1B 6 10 2A 5 21 2B 2 25 3 15 11 23 30 6E 22- 6NA 139 Question: Assuming we are not limited by outside sources, such as raw materials supply, demand, or the possibility of breakdown or scheduled downtime, what is the actual throughput rate of the process, in items/min? Please use at least three significant figures in your calculations. 1234 4 Repair 1 4 R5 35

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock