Question: The activities are performed sequentially as listed. Every 30 work parts, the cutting tools in the machine must be changed. This irregular cycle takes 3.0

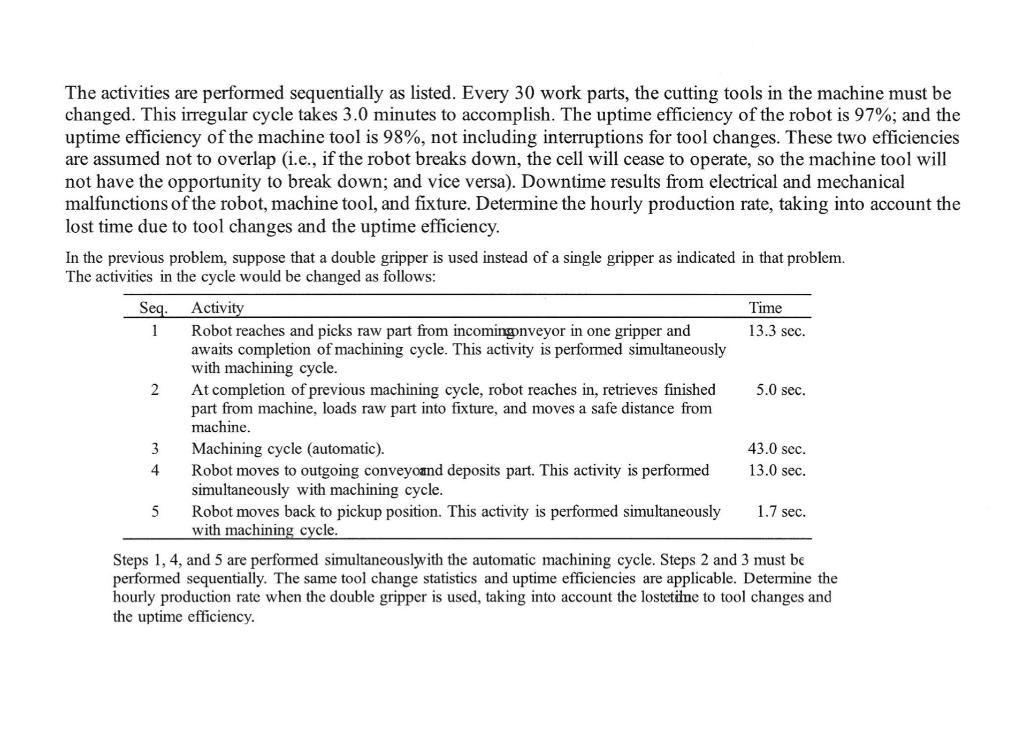

The activities are performed sequentially as listed. Every 30 work parts, the cutting tools in the machine must be changed. This irregular cycle takes 3.0 minutes to accomplish. The uptime efficiency of the robot is 97%; and the uptime efficiency of the machine tool is 98%, not including interruptions for tool changes. These two efficiencies are assumed not to overlap (i.e., if the robot breaks down, the cell will cease to operate, so the machine tool will not have the opportunity to break down; and vice versa). Downtime results from electrical and mechanical malfunctions of the robot, machine tool, and fixture. Determine the hourly production rate, taking into account the lost time due to tool changes and the uptime efficiency. In the previous problem, suppose that a double gripper is used instead of a single gripper as indicated in that problem. The activities in the cycle would be changed as follows: Steps 1,4 , and 5 are performed simultaneouslyith the automatic machining cycle. Steps 2 and 3 must be performed sequentially. The same tool change statistics and uptime efficiencies are applicable. Determine the hourly production rate when the double gripper is used, taking into account the lostetiine to tool changes and the uptime efficiency

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts