Question: The CXO process for making shirts starts with a batch cutting machine, where the shirt material arranged in layers by an operator, is cut into

The CXO process for making shirts starts with a batch cutting machine, where the shirt material arranged in layers by an operator, is cut into different pieces (collars, sleeves, etc.). Each layer corresponds to one shirt, and 45 layers are cut at a time, by a computer controlled machine. The fixed time is 20 minutes, and each layer takes 2 minutes to arrange before starting the cutting machine.

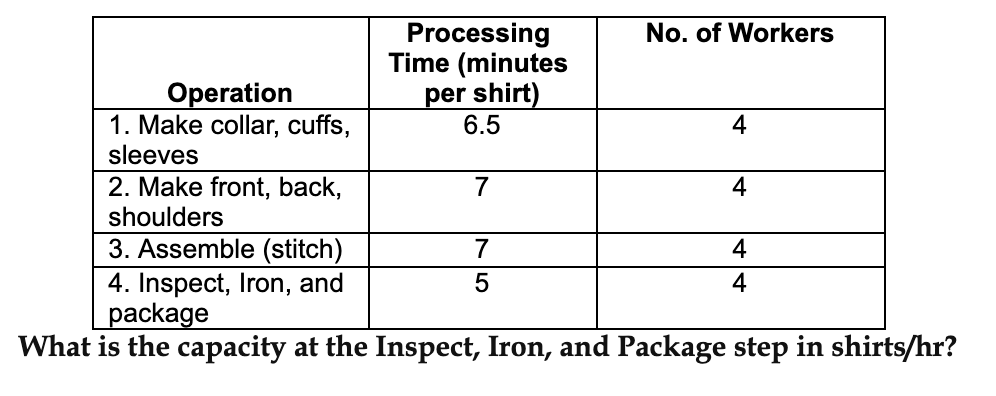

After cutting, the shirts go through several sewing steps, one at a time. The data for each of the steps is given below, along with the number of workers working on each step. Determine the bottleneck operation (including the cutting step).

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts