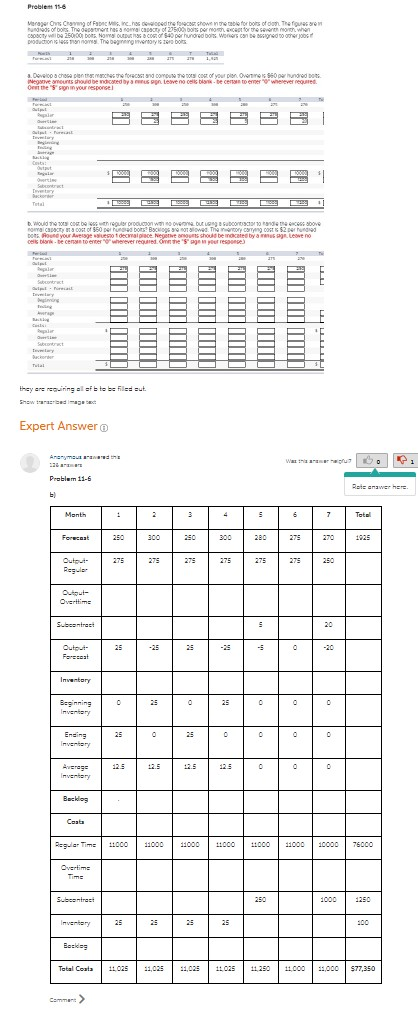

Question: the expert answer is missing output overtime, subcontract, inventory, backlog, costs overtime, subcontract, and backlog. I am not suppossed to have any blanks. can you

the expert answer is missing output overtime, subcontract, inventory, backlog, costs overtime, subcontract, and backlog. I am not suppossed to have any blanks. can you help me correct the expert answer?

the expert answer is missing output overtime, subcontract, inventory, backlog, costs overtime, subcontract, and backlog. I am not suppossed to have any blanks. can you help me correct the expert answer?

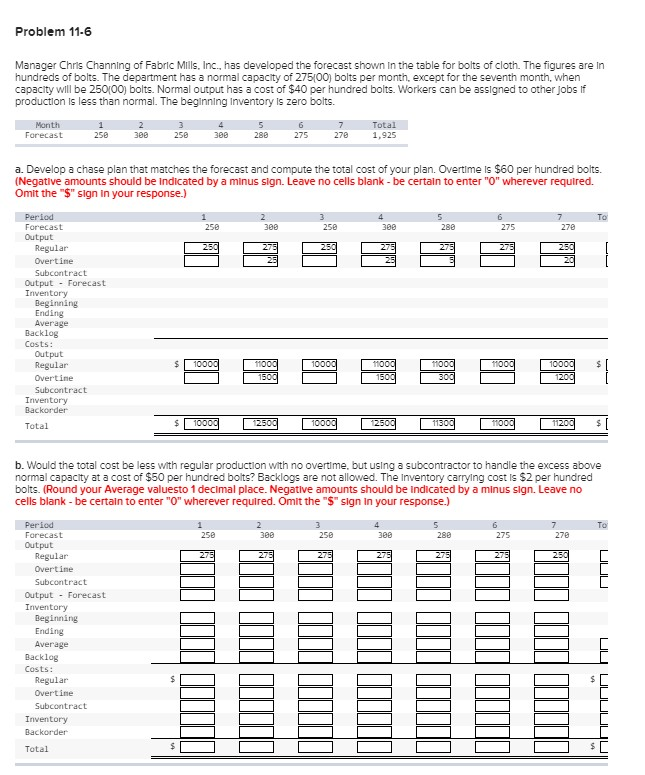

Problem 11-6 Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown In the table for bolts of cloth. The figures are In hundreds of bolts. The department has a normal capacity of 275 00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be asslgned to other Jobs If production is less than normal. The beginning Inventory is zero bolts. Forecast 308 308 275 270 1,925 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. Negative amounts should be Indicated by a minus sign. Leave no cells blank be certain to enter "O" wherever required. Omit the "$" sign in your response.) Forecast 300 300 278 Subcontract Output Forecast Deginning Ending Average Backlog Costs: Inventory Backorder Total b. Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above normal capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The Inventory carryling cost Is $2 per hundred bolts. (Round your Average valuesto 1 decimal place. Negative amounts should be Indicated by a minus sign. Leave no cells blank - be certaln to enter "O" wherever required. Omit the "$" sign in your response.) Forecast 258 300 258 308 288 270 Output Forecast Deginning Ending Average Backlog Costs: Backorder Total Problem 11-6 Manager Chris Channing of Fabric Mills, Inc., has developed the forecast shown In the table for bolts of cloth. The figures are In hundreds of bolts. The department has a normal capacity of 275 00) bolts per month, except for the seventh month, when capacity will be 250(00) bolts. Normal output has a cost of $40 per hundred bolts. Workers can be asslgned to other Jobs If production is less than normal. The beginning Inventory is zero bolts. Forecast 308 308 275 270 1,925 a. Develop a chase plan that matches the forecast and compute the total cost of your plan. Overtime is $60 per hundred bolts. Negative amounts should be Indicated by a minus sign. Leave no cells blank be certain to enter "O" wherever required. Omit the "$" sign in your response.) Forecast 300 300 278 Subcontract Output Forecast Deginning Ending Average Backlog Costs: Inventory Backorder Total b. Would the total cost be less with regular production with no overtime, but using a subcontractor to handle the excess above normal capacity at a cost of $50 per hundred bolts? Backlogs are not allowed. The Inventory carryling cost Is $2 per hundred bolts. (Round your Average valuesto 1 decimal place. Negative amounts should be Indicated by a minus sign. Leave no cells blank - be certaln to enter "O" wherever required. Omit the "$" sign in your response.) Forecast 258 300 258 308 288 270 Output Forecast Deginning Ending Average Backlog Costs: Backorder Total

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts