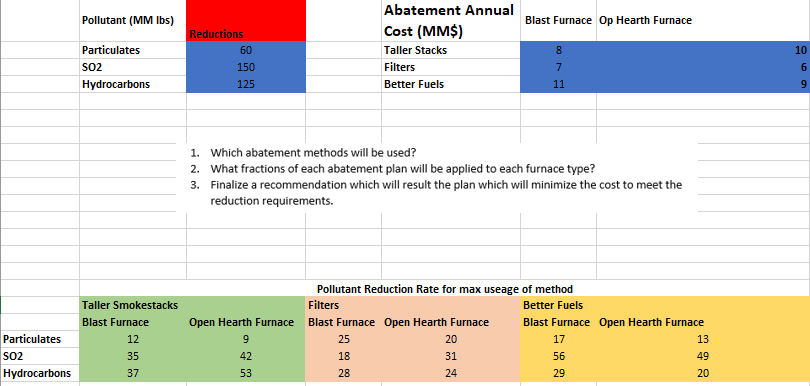

Question: The objective is to minimize our cost while implementing the bottom portion of abatement methods. One single method cannot be used and fractions of each

The objective is to minimize our cost while implementing the bottom portion of abatement methods. One single method cannot be used and fractions of each method applied to each of the two furnace types is required. I am currently struggling with setting up the constraints and flows.

Pollutant (MM lbs) Blast Furnace Op Hearth Furnace 8 Abatement Annual Cost (MMS) Taller Stacks Filters Better Fuels Particulates SO2 Hydrocarbons 10 Reductions 60 150 125 7 6 9 11 1. Which abatement methods will be used? 2. What fractions of each abatement plan will be applied to each furnace type? 3. Finalize a recommendation which will result the plan which will minimize the cost to meet the reduction requirements. Particulates SO2 Hydrocarbons Taller Smokestacks Blast Furnace 12 35 37 Pollutant Reduction Rate for max useage of method Filters Better Fuels Open Hearth Furnace Blast Furnace Open Hearth Furnace Blast Furnace Open Hearth Furnace 9 25 20 17 13 42 18 31 56 49 53 28 24 29 20 Pollutant (MM lbs) Blast Furnace Op Hearth Furnace 8 Abatement Annual Cost (MMS) Taller Stacks Filters Better Fuels Particulates SO2 Hydrocarbons 10 Reductions 60 150 125 7 6 9 11 1. Which abatement methods will be used? 2. What fractions of each abatement plan will be applied to each furnace type? 3. Finalize a recommendation which will result the plan which will minimize the cost to meet the reduction requirements. Particulates SO2 Hydrocarbons Taller Smokestacks Blast Furnace 12 35 37 Pollutant Reduction Rate for max useage of method Filters Better Fuels Open Hearth Furnace Blast Furnace Open Hearth Furnace Blast Furnace Open Hearth Furnace 9 25 20 17 13 42 18 31 56 49 53 28 24 29 20Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts