Question: The process below is a simple process for a bakery to make cookies. It consists of mixing the ingredients, letting the dough chill, shaping the

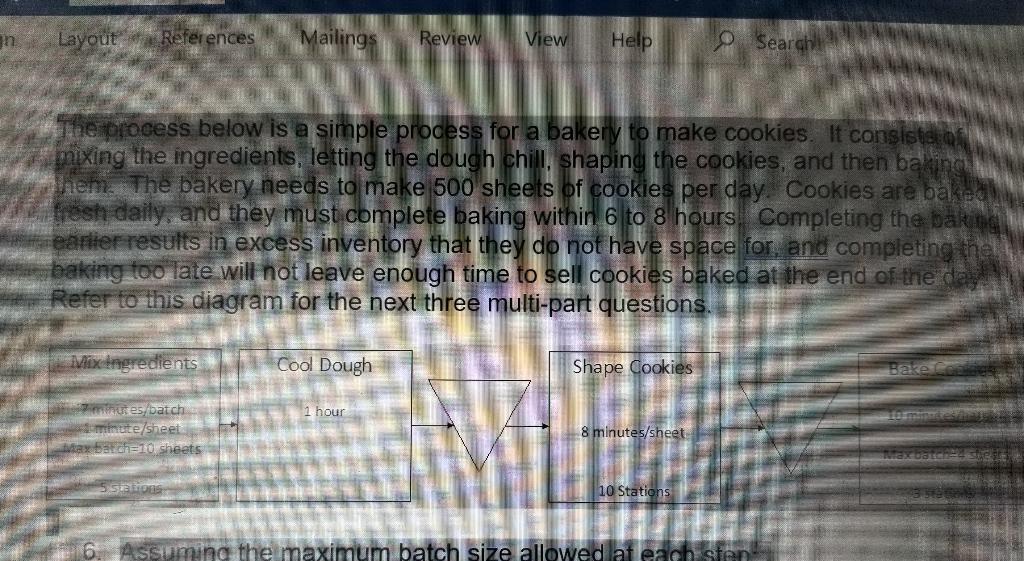

The process below is a simple process for a bakery to make cookies. It consists of mixing the ingredients, letting the dough chill, shaping the cookies, and then baking them. The bakery needs to make 500 sheets of cookies per day. Cookies are baked fresh daily, and they must complete baking within 6 to 8 hours. Completing the baking earlier results in excess inventory that they do not have space for, and completing the baking too late will not leave enough time to sell cookies baked at the end of the day. Refer to this diagram for the next three multi-part questions. 6. Assuming the maximum batch size allowed at each step: a. What is the capacity at each step? b. How long does it take to complete the first sheet of cookies if the dough is made fresh each morning? 1 hr and 18 min c. If the cookie dough is made the day before, does the process produce 500 sheets within 6-8 hours? 7. If the bakery wants to expand to allow 700 sheets of cookies per day, what changes, if any, are needed at each step in the process? Assume cookie dough is made the day before. 8. Instead, if the bakery is most interested in balancing the flow of the production process: a. What changes would you make to have the capacity of each step within 0.1 sheets/min of the other steps? Your changes must still support the demand for 500 sheets/day. b. What are the benefits of balanced flow and your recommended changes?

The process below is a simple process for a bakery to make cookies. It consists of mixing the ingredients, letting the dough chill, shaping the cookies, and then baking them. The bakery needs to make 500 sheets of cookies per day. Cookies are baked fresh daily, and they must complete baking within 6 to 8 hours. Completing the baking earlier results in excess inventory that they do not have space for, and completing the baking too late will not leave enough time to sell cookies baked at the end of the day. Refer to this diagram for the next three multi-part questions. 6. Assuming the maximum batch size allowed at each step: a. What is the capacity at each step? b. How long does it take to complete the first sheet of cookies if the dough is made fresh each morning? 1 hr and 18 min c. If the cookie dough is made the day before, does the process produce 500 sheets within 6-8 hours? 7. If the bakery wants to expand to allow 700 sheets of cookies per day, what changes, if any, are needed at each step in the process? Assume cookie dough is made the day before. 8. Instead, if the bakery is most interested in balancing the flow of the production process: a. What changes would you make to have the capacity of each step within 0.1 sheets/min of the other steps? Your changes must still support the demand for 500 sheets/day. b. What are the benefits of balanced flow and your recommended changes?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts