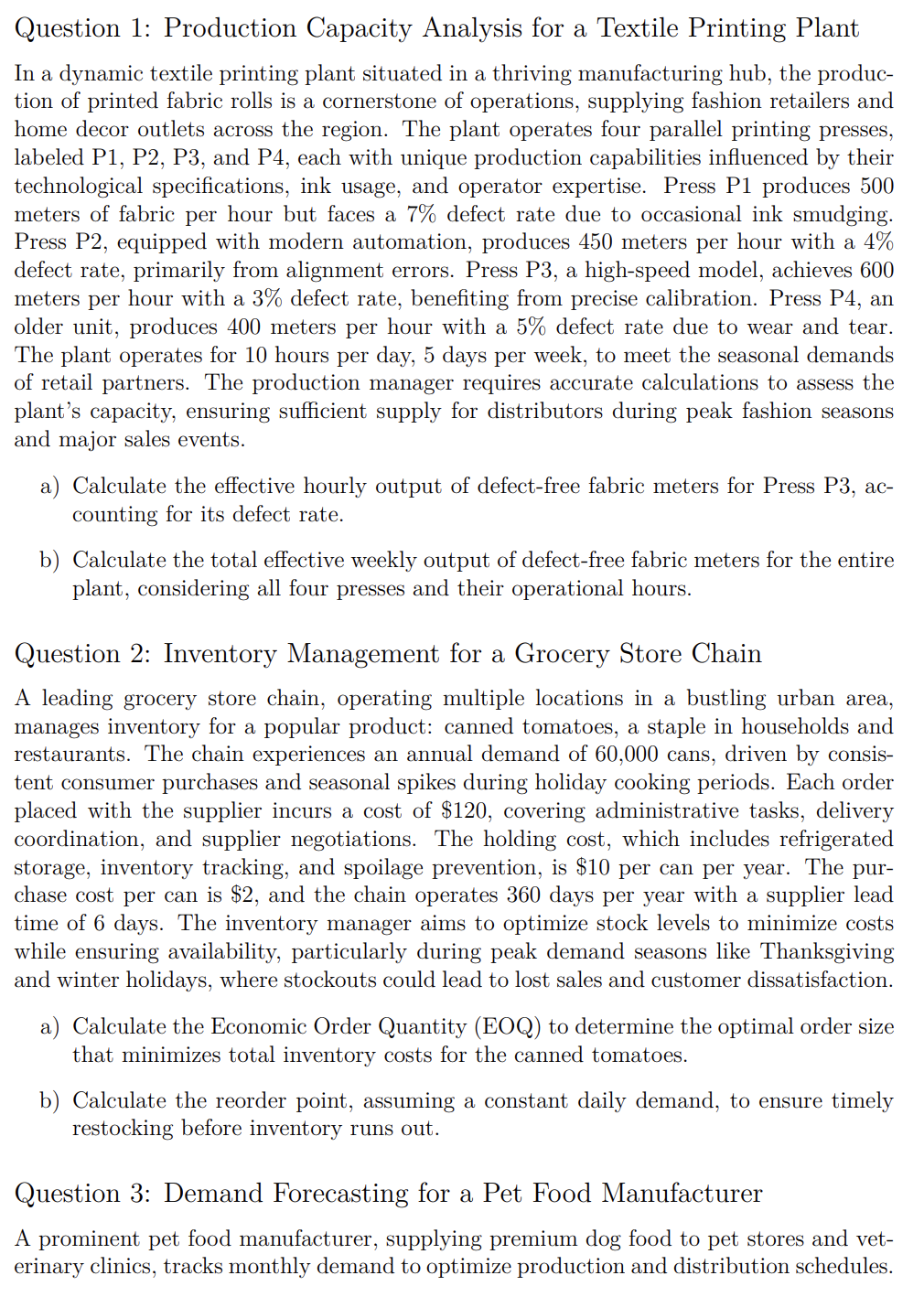

Question: The product's popularity is driven by its high - quality ingredients and targeted market - ing campaigns, attracting pet owners across urban and suburban markets.

The product's popularity is driven by its highquality ingredients and targeted market

ing campaigns, attracting pet owners across urban and suburban markets. The demand

data for the past six months, carefully recorded to reflect seasonal trends, promotional

discounts, and pet adoption events, is presented in the table below. Accurate forecasting

is critical for the manufacturer to manage raw material procurement, schedule produc

tion runs, and coordinate logistics with distributors, ensuring pet stores are wellstocked

without excess inventory that could increase storage costs.

Table : Monthly Demand Data for Premium Dog Food

a Using a month simple moving average, calculate the forecasted demand for month

to guide the manufacturer's production planning.

b Using exponential smoothing with a smoothing constant of and an initial fore

cast for month of bags, calculate the forecasted demand for month

Question : Production Scheduling for a Furniture Assembly Workshop

A specialized furniture assembly workshop produces two types of wooden chairs, Model

X and Model Y on a single assembly line to supply home furnishing retailers. The

workshop operates in a competitive market, requiring precise scheduling to meet delivery

deadlines and maintain customer satisfaction. Producing Model X chairs takes hours

per unit due to detailed craftsmanship, while Model Y chairs require hours per unit

because of additional finishing processes. Switching the assembly line from Model X to

Model Y requires a setup time of hours to reconfigure tools and adjust workstations,

while switching from Model Y to Model X takes hours. The workshop must produce

units of Model X and units of Model Y in a week to fulfill a major order, with

the assembly line available for hours per week. The production manager needs to

calculate key scheduling metrics to optimize the production sequence, prioritizing the

sequence that minimizes setup time to maximize efficiency and meet deadlines.

a Calculate the total production time required for units of Model X and units

of Model Y excluding setup times.

b Calculate the total time production setup required to produce the required

units, using the sequence that minimizes setup time.

Question : Process Flowchart for Furniture Assembly

Based on the production process described in Question draw a detailed flowchart to

illustrate the sequence of steps for producing Model X and Model Y chairs in the furniture

assembly workshop. The flowchart should include the following steps: receiving raw ma

terials wood and hardware for both chair models setting up the assembly line for Model

X producing Model X chairs, setting up the assembly line for Model Y producing Model

Y chairs, inspecting finished chairs, and packaging for delivery. Incorporate decision

points for selecting which chair model to produce first, handling defective units assume

a defect rate for both models and looping to process additional uits. Clearly

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock