Question: The question below is similar to this solution on CHEGG: https://www.chegg.com/homework-help/Supply-Chain-Management-6th-edition-chapter-9-problem-1E-solution-9780133800203 (I am asking this question again because the last chegg expert did not do

The question below is similar to this solution on CHEGG: https://www.chegg.com/homework-help/Supply-Chain-Management-6th-edition-chapter-9-problem-1E-solution-9780133800203

(I am asking this question again because the last chegg expert did not do it correctly)

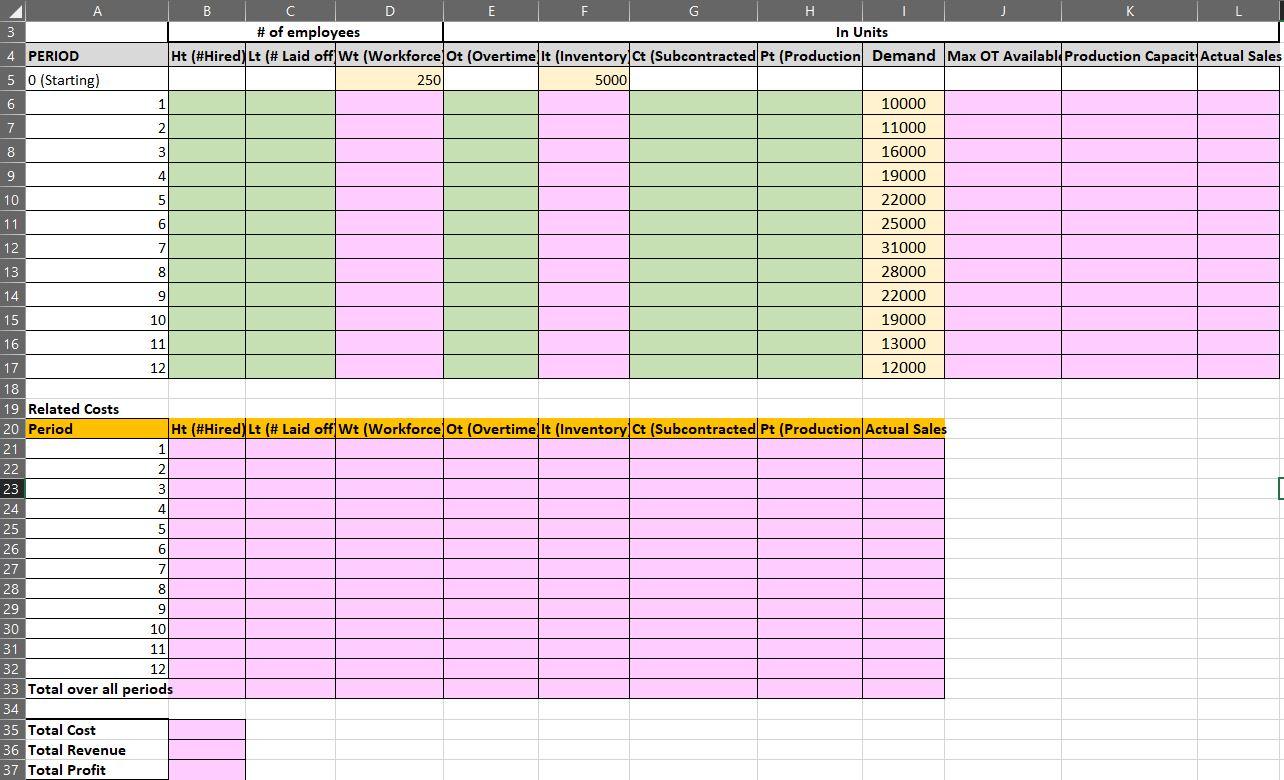

Please use the info. below and EXCEL SOLVER, to come up with the most optimal aggregate Production plan via EXCEL.

you may need to set up constraints. Please see the Excel screenshot below that shows you how to setup your template

| Costs | |

| Regular Time Labour | 15 |

| Overtime Labour | 22 |

| Subcontracting cost (per unit) | 74 |

| Inventory carrying cost (per unit per month) | 3 |

| Material cost (per unit) | 40 |

| Selling Price (per unit) | 125 |

| Hiring Cost (per new employee) | 1000 |

| Lay-off cost (per laid off employee) | 2000 |

| Starting Inventory | 5000 |

| Desired Ending Inventory | 5000 |

| Overtime Limit (number of units produced per employee) | 10 |

| Production Capacity (per employee per month) | 80 units |

| Starting Workforce | 250 workers |

| Labour hours per unit | 2 |

| MAX overtime per month per employee, HOURS | 20 |

| # of working days per month | 20 |

| # of hours per day | 8 |

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock