Question: The question is based off of E301 for streams 13 and 24. please answer the question based off of those streams not E303 or anything

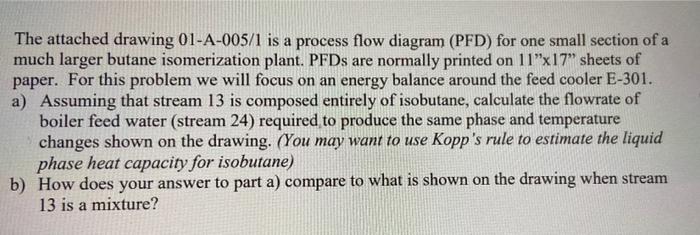

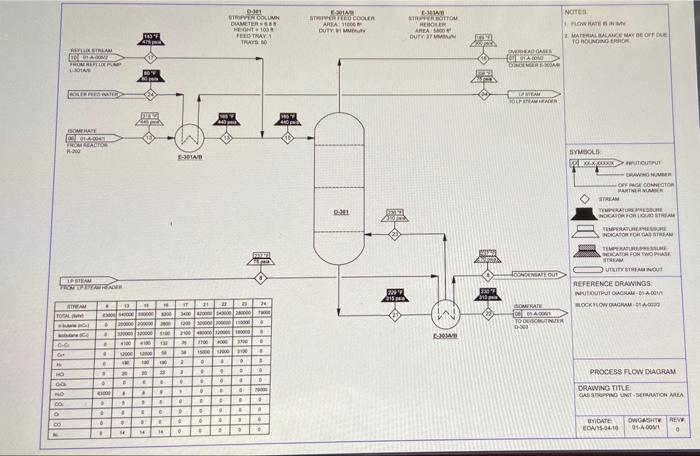

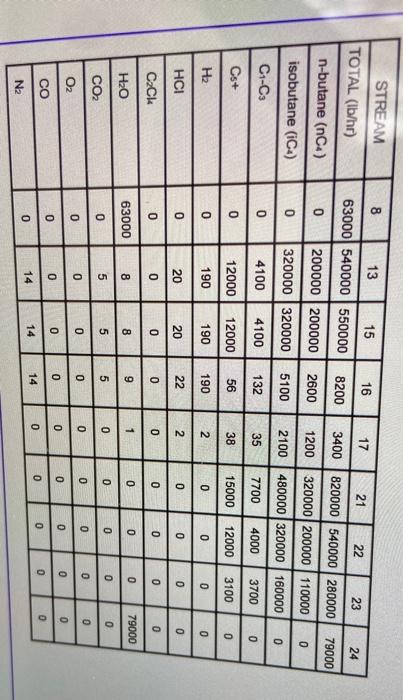

The attached drawing 01-A-005/1 is a process flow diagram (PFD) for one small section of a much larger butane isomerization plant. PFDs are normally printed on 11"x17" sheets of paper. For this problem we will focus on an energy balance around the feed cooler E-301. a) Assuming that stream 13 is composed entirely of isobutane, calculate the flowrate of boiler feed water (stream 24) required to produce the same phase and temperature changes shown on the drawing. (You may want to use Kopp's rule to estimate the liquid phase heat capacity for isobutane) b) How does your answer to part a) compare to what is shown on the drawing when stream 13 is a mixture? PER COLUMN DIAMETER HH t ln FEED THAY TRATAM ES STAGED COOLER AREA: 1100 DUTY STROOITOU REOLER AREA DUTTI NOTE POWER MATERIAL BALANCE MADE OF OVE TO ROUND ERROR 1457 REFLISTRIAN TAG PRETO MARS UICE RA 0 FOR ORT COS TRACT RO -AB SYMBOLS XX TOUSUT NER OFM CONTOR PARTNER STREAM TERATURE STREAM TEMPERATURE NOICATOR FORGARSTRAN TEMPERATURA BARCH FOR TWO PE URITYSRAU NOUT GONNALOUS LETE TEFALTA REFERENCE DRAWINGS OUTPUT AGAMA OKROWDAGRAM A1 + AM 34 TOTAL M 11 23 000 000000 120000 1000000 BOMERATE ODNA TO DOMINU 0-30 . 3 C-C . . . . 1 PROCESS FLOW DIAGRAM . . GO HO 100 . . . . . . . . . . . . . . . . DRAWING TITLE GAS SHOPPING UNTILATION MEA . . GO . . . . IDATE EONI 0410 OWGHT REVE 914.00 STREAM 8 13 15 16 17 TOTAL (Ib/hr) 21 22 23 63000 540000 550000 24 8200 3400 820000 540000 280000 n-butane (nCA) 79000 0 200000 200000 2600 1200 320000 200000 110000 0 isobutane (iC) 0 320000 320000 5100 2100 480000 320000160000 0 C1-Cs 0 4100 4100 132 35 7700 4000 3700 0 Cs+ 0 12000 12000 56 38 15000 12000 3100 0 Hz 0 190 190 190 2 O 0 0 oo HCI 0 20 20 22 2 0 0 0 | 0 0 Cock O 0 0 0 0 0 0 63000 8 8 9 1 79000 0 H2O 0 0 0 5 5 ololo 0 0 0 0 CO2 o ololo 0 0 0 Oon 0 0 O2 O 0 0 0 0 0 0 01 CO 0 0 0 0 14 0 14 14 0 N2 STRIPPER COLUMN DIAMETER-581 HEIGHT 103 FEED TRAY 1 TRAYS 50 E-3148 STRIPPER FEED COOLER AREA: 11000 DUTY: 91 MB 143 "F 475 E-3034 STRIPPER BOTTOM REBOILER AREA DUTY 27 NOTES POWROTESNO 2. MATERIAL BALANCE TORCUNONGOR REFLUX STREAM 10 054-002 FROM REFLUX PUMP L-301AE OD DANS 607 80 pais OLER FEED WATER LOTEAM TOUW 315 180 T 140 1657 440 MATE 01 A 00473 OM REACTOR 202 SYMBOLS E-301A/B BERDE D-301 NOONG FILES REFERENCE DAWINGS The attached drawing 01-A-005/1 is a process flow diagram (PFD) for one small section of a much larger butane isomerization plant. PFDs are normally printed on 11"x17" sheets of paper. For this problem we will focus on an energy balance around the feed cooler E-301. a) Assuming that stream 13 is composed entirely of isobutane, calculate the flowrate of boiler feed water (stream 24) required to produce the same phase and temperature changes shown on the drawing. (You may want to use Kopp's rule to estimate the liquid phase heat capacity for isobutane) b) How does your answer to part a) compare to what is shown on the drawing when stream 13 is a mixture? PER COLUMN DIAMETER HH t ln FEED THAY TRATAM ES STAGED COOLER AREA: 1100 DUTY STROOITOU REOLER AREA DUTTI NOTE POWER MATERIAL BALANCE MADE OF OVE TO ROUND ERROR 1457 REFLISTRIAN TAG PRETO MARS UICE RA 0 FOR ORT COS TRACT RO -AB SYMBOLS XX TOUSUT NER OFM CONTOR PARTNER STREAM TERATURE STREAM TEMPERATURE NOICATOR FORGARSTRAN TEMPERATURA BARCH FOR TWO PE URITYSRAU NOUT GONNALOUS LETE TEFALTA REFERENCE DRAWINGS OUTPUT AGAMA OKROWDAGRAM A1 + AM 34 TOTAL M 11 23 000 000000 120000 1000000 BOMERATE ODNA TO DOMINU 0-30 . 3 C-C . . . . 1 PROCESS FLOW DIAGRAM . . GO HO 100 . . . . . . . . . . . . . . . . DRAWING TITLE GAS SHOPPING UNTILATION MEA . . GO . . . . IDATE EONI 0410 OWGHT REVE 914.00 STREAM 8 13 15 16 17 TOTAL (Ib/hr) 21 22 23 63000 540000 550000 24 8200 3400 820000 540000 280000 n-butane (nCA) 79000 0 200000 200000 2600 1200 320000 200000 110000 0 isobutane (iC) 0 320000 320000 5100 2100 480000 320000160000 0 C1-Cs 0 4100 4100 132 35 7700 4000 3700 0 Cs+ 0 12000 12000 56 38 15000 12000 3100 0 Hz 0 190 190 190 2 O 0 0 oo HCI 0 20 20 22 2 0 0 0 | 0 0 Cock O 0 0 0 0 0 0 63000 8 8 9 1 79000 0 H2O 0 0 0 5 5 ololo 0 0 0 0 CO2 o ololo 0 0 0 Oon 0 0 O2 O 0 0 0 0 0 0 01 CO 0 0 0 0 14 0 14 14 0 N2 STRIPPER COLUMN DIAMETER-581 HEIGHT 103 FEED TRAY 1 TRAYS 50 E-3148 STRIPPER FEED COOLER AREA: 11000 DUTY: 91 MB 143 "F 475 E-3034 STRIPPER BOTTOM REBOILER AREA DUTY 27 NOTES POWROTESNO 2. MATERIAL BALANCE TORCUNONGOR REFLUX STREAM 10 054-002 FROM REFLUX PUMP L-301AE OD DANS 607 80 pais OLER FEED WATER LOTEAM TOUW 315 180 T 140 1657 440 MATE 01 A 00473 OM REACTOR 202 SYMBOLS E-301A/B BERDE D-301 NOONG FILES REFERENCE DAWINGS

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts