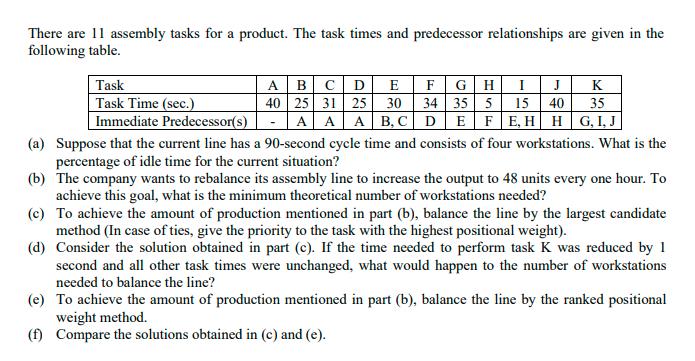

Question: There are 11 assembly tasks for a product. The task times and predecessor relationships are given in the following table. Task Task Time (sec.)

There are 11 assembly tasks for a product. The task times and predecessor relationships are given in the following table. Task Task Time (sec.) A | B C D E F GH I J K 40 25 31 25 30 34 35 5 15 40 35 AAAB, C D E FE, H HG, I, J Immediate Predecessor(s) (a) Suppose that the current line has a 90-second cycle time and consists of four workstations. What is the percentage of idle time for the current situation? (b) The company wants to rebalance its assembly line to increase the output to 48 units every one hour. To achieve this goal, what is the minimum theoretical number of workstations needed? (c) To achieve the amount of production mentioned in part (b), balance the line by the largest candidate method (In case of ties, give the priority to the task with the highest positional weight). (d) Consider the solution obtained in part (c). If the time needed to perform task K was reduced by 1 second and all other task times were unchanged, what would happen to the number of workstations needed to balance the line? (e) To achieve the amount of production mentioned in part (b), balance the line by the ranked positional weight method. (f) Compare the solutions obtained in (c) and (e).

Step by Step Solution

3.46 Rating (159 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts