Question: This case study involves the Grainger Inc. company on page 4 4 9 - 4 5 1 in the textbook. This exercise involves analyzing /

This case study involves the Grainger Inc. company on page in the textbook. This exercise involves analyzingcalculating the cost of changingreengineering the distribution center location in the company's supply chain. Your job is to calculate the total costs of the old system and the total costs of the new system. After calculating these costs, you should be able to answer the questions mentioned in the case.

To solve this problem you have to assume that you are working for the company, and your bosssupervisor is asking you to look at the current system and if a new system would be worthwhile to consider. Since this is an MBA level course, I expect everyone to be able to do this.

I expect everyone of you to do this case on your own without any help from me or the instructional coach Dr katie Lopez You're welcome to use the bulletin board to ask any questions or to get help from others in the class. And, if you can figure out the answers, you are welcome to help others too. But, please try to answer the questions in away that it will help them to think, instead of giving all the answers to copy.

You should use MS excel to calculate all the costs involved. Please copy all your excel work to a MS Word document. I need to see the individual cost and the total costs for the old system and the new system.

Hints:

You need to calculate the following costs first:

Port processing fee for both ports, LA and Seattle.

The transportationrail costs from these two ports to Kansas City.

Unloading and quality check costs at Kansas City.

Calculate the total cost for transporting the goods by trucks from Kansas City distribution center to all nine cities.

Total costs for current system will be the total of and

Calculate the total cost for the new system

Port processing fee for both ports, LA and Seattle

Transportationrail cost from Seattle port to LA

Unloading and quality check cost at LA

LA Distribution Operating costs

Transportation costs by rail for of the goods to Kansas City

Calculate the total cost for transporting the goods by trucks from Kansas City to the other cities.

Total costs for the new system will be the total of and

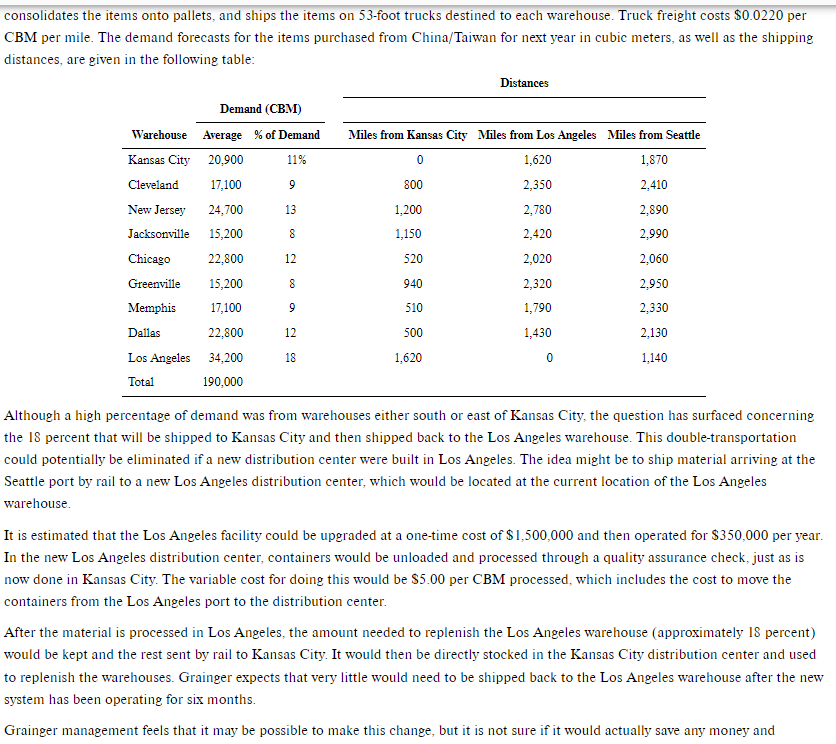

Answer question to on page Submit your MS Word document here.consolidates the items onto pallets, and ships the items on foot trucks destined to each warehouse. Truck freight costs $ per

CBM per mile. The demand forecasts for the items purchased from ChinaTaiwan for next year in cubic meters, as well as the shipping

distances, are given in the following table:

Distances

Although a high percentage of demand was from warehouses either south or east of Kansas City, the question has surfaced concerning

the percent that will be shipped to Kansas City and then shipped back to the Los Angeles warehouse. This doubletransportation

could potentially be eliminated if a new distribution center were built in Los Angeles. The idea might be to ship material arriving at the

Seattle port by rail to a new Los Angeles distribution center, which would be located at the current location of the Los Angeles

warehouse.

It is estimated that the Los Angeles facility could be upgraded at a onetime cost of $ and then operated for $ per year.

In the new Los Angeles distribution center, containers would be unloaded and processed through a quality assurance check, just as is

now done in Kansas City. The variable cost for doing this would be $ per CBM processed, which includes the cost to move the

containers from the Los Angeles port to the distribution center.

After the material is processed in Los Angeles, the amount needed to replenish the Los Angeles warehouse approximately percent

would be kept and the rest sent by rail to Kansas City. It would then be directly stocked in the Kansas City distribution center and used

to replenish the warehouses. Grainger expects that very little would need to be shipped back to the Los Angeles warehouse after the new

system has been operating for six months.

Grainger management feels that it may be possible to make this change, but it is not sure if it would actually save any money and

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock