Question: This is a capital budgeting, make or buy problem with three mutually exclusive alternatives. You must apply what you learned in the previous make/buy section

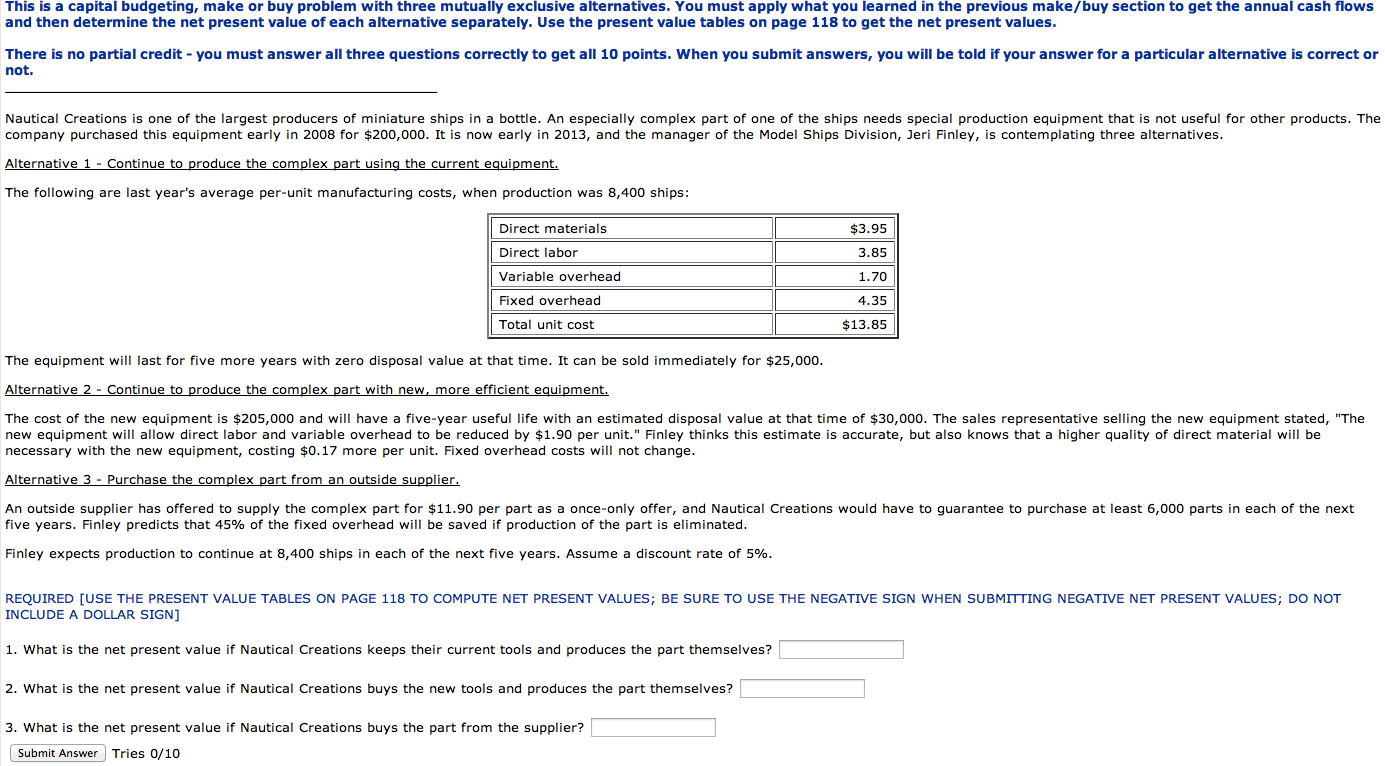

This is a capital budgeting, make or buy problem with three mutually exclusive alternatives. You must apply what you learned in the previous make/buy section to get the annual cash flows and then determine the net present value of each alternative separately. Use the present value tables on page 118 to getthe net present values. There is no partial credit you must answer all three questions correctly to get all 10 points. When you submit answers, you will be told if your answer for a particular alternative is correct or not Nautical Creations is one of the largest producers of miniature ships in a bottle. An especially complex part of one of the ships needs special production equipment that is not useful for other products. The company purchased this equipment early in 2008 for $200,000 It is now early in 2013, and the manager of the Model Ships Division, Jeri Finley, is contemplating three alternatives Alternative 1 Continue to produce the complex part using the current equipmen The following are last year's average per unit manufacturing costs, when production was 8,400 ships: $3.95 Direct materials Direct labor 3.85 Variable overhead 1.70 Fixed overhead 35 $13.85 Total unit cost The equipment will last for five more years with zero disposal value at that time. It can be sold immediately for $25,000. Alternative 2 Continue to produce the complex part with new more efficient equipmen The cost of the new equipment is $205,000 and will have a five-year useful life with an estimated disposal value at that time of $30,000. The sales representative selling the new equipment stated, "The new equipment will allow direct labor and variable overhead to be reduced by $1.90 per unit." Finley thinks this estimate is accurate, but also knows that a higher quality of direct material will be necessary with the new equipment, costing $0.17 more per unit. Fixed overhead costs will not change Alternative 3 Purchase the complex part from an outside supplier. An outside supplier has offered to supply the complex part for $11.90 per part as a once-only offer, and Nautical Creations would have to guarantee to purchase at least 6,000 parts in each of the next five years. Finley predicts that 45% of the fixed overhead will be saved if production of the part is eliminated Finley expects production to continue at 8,400 ships in each of the next five years. Assume a discount rate of 5% REQUIRED IUSE THE PRESENT VALUE BLES ON PAGE 118 TO COMPUTE NET PRESENT VALUES BE SURE TO USE THE NEGATIVE SIGN WHEN SUBMITTING NEGATIVE NET PRESENT VALUES: DO NOT INCLUDE A DOLLAR SIGN] 1. What is the net present value if Nautical Creations keeps their current tools and produces the part themselves? 2. What is the net present value if Nautical Creations buys the new tools and produces the part themselves? 3. What is the net present value if Nautical Creations buys the part from the supplier? Submit Ans Tries 0/10 This is a capital budgeting, make or buy problem with three mutually exclusive alternatives. You must apply what you learned in the previous make/buy section to get the annual cash flows and then determine the net present value of each alternative separately. Use the present value tables on page 118 to getthe net present values. There is no partial credit you must answer all three questions correctly to get all 10 points. When you submit answers, you will be told if your answer for a particular alternative is correct or not Nautical Creations is one of the largest producers of miniature ships in a bottle. An especially complex part of one of the ships needs special production equipment that is not useful for other products. The company purchased this equipment early in 2008 for $200,000 It is now early in 2013, and the manager of the Model Ships Division, Jeri Finley, is contemplating three alternatives Alternative 1 Continue to produce the complex part using the current equipmen The following are last year's average per unit manufacturing costs, when production was 8,400 ships: $3.95 Direct materials Direct labor 3.85 Variable overhead 1.70 Fixed overhead 35 $13.85 Total unit cost The equipment will last for five more years with zero disposal value at that time. It can be sold immediately for $25,000. Alternative 2 Continue to produce the complex part with new more efficient equipmen The cost of the new equipment is $205,000 and will have a five-year useful life with an estimated disposal value at that time of $30,000. The sales representative selling the new equipment stated, "The new equipment will allow direct labor and variable overhead to be reduced by $1.90 per unit." Finley thinks this estimate is accurate, but also knows that a higher quality of direct material will be necessary with the new equipment, costing $0.17 more per unit. Fixed overhead costs will not change Alternative 3 Purchase the complex part from an outside supplier. An outside supplier has offered to supply the complex part for $11.90 per part as a once-only offer, and Nautical Creations would have to guarantee to purchase at least 6,000 parts in each of the next five years. Finley predicts that 45% of the fixed overhead will be saved if production of the part is eliminated Finley expects production to continue at 8,400 ships in each of the next five years. Assume a discount rate of 5% REQUIRED IUSE THE PRESENT VALUE BLES ON PAGE 118 TO COMPUTE NET PRESENT VALUES BE SURE TO USE THE NEGATIVE SIGN WHEN SUBMITTING NEGATIVE NET PRESENT VALUES: DO NOT INCLUDE A DOLLAR SIGN] 1. What is the net present value if Nautical Creations keeps their current tools and produces the part themselves? 2. What is the net present value if Nautical Creations buys the new tools and produces the part themselves? 3. What is the net present value if Nautical Creations buys the part from the supplier? Submit Ans Tries 0/10

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts