Question: This is a Reaction/Chemical Reactor Engineering question. Please provide full, clear working for the answer with legible handwriting and explanation, if needed. Thank you so

This is a Reaction/Chemical Reactor Engineering question. Please provide full, clear working for the answer with legible handwriting and explanation, if needed.

Thank you so much.

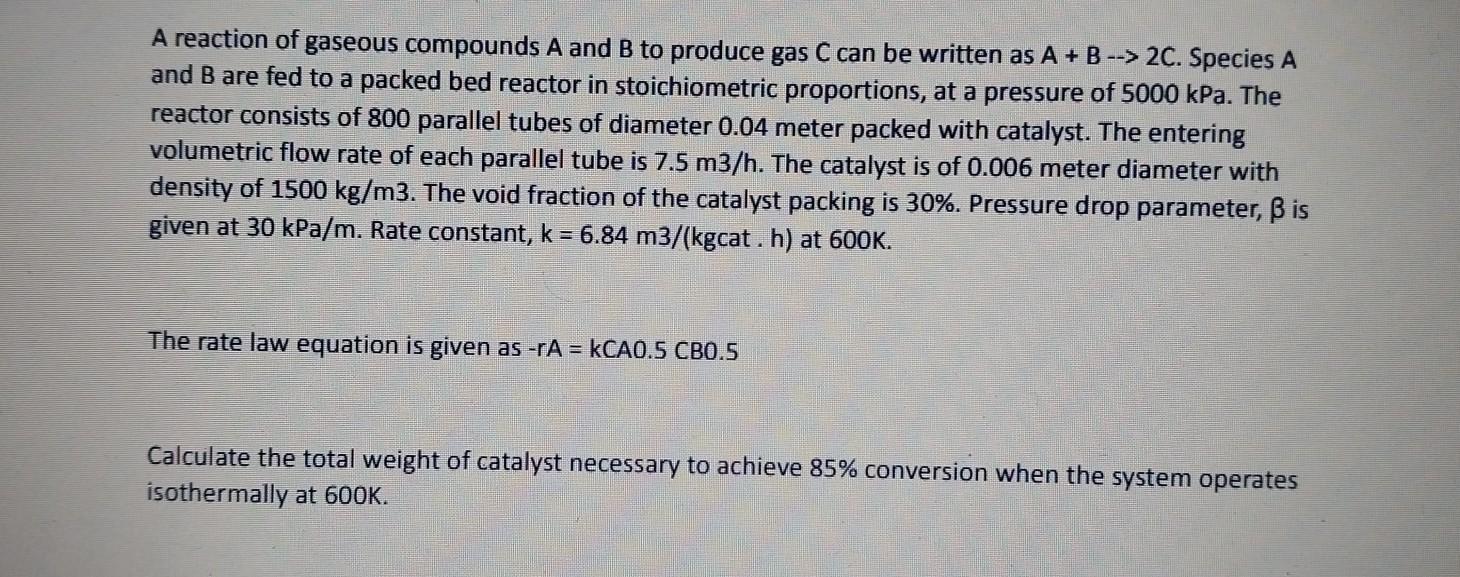

A reaction of gaseous compounds A and B to produce gas C can be written as A+B2C. Species A and B are fed to a packed bed reactor in stoichiometric proportions, at a pressure of 5000kPa. The reactor consists of 800 parallel tubes of diameter 0.04 meter packed with catalyst. The entering volumetric flow rate of each parallel tube is 7.5m3/h. The catalyst is of 0.006 meter diameter with density of 1500kg/m3. The void fraction of the catalyst packing is 30%. Pressure drop parameter, is given at 30kPa/m. Rate constant, k=6.84m3/( kgcat. h) at 600K. The rate law equation is given as rA=kCAO.5CBO.5 Calculate the total weight of catalyst necessary to achieve 85% conversion when the system operates isothermally at 600K. A reaction of gaseous compounds A and B to produce gas C can be written as A+B2C. Species A and B are fed to a packed bed reactor in stoichiometric proportions, at a pressure of 5000kPa. The reactor consists of 800 parallel tubes of diameter 0.04 meter packed with catalyst. The entering volumetric flow rate of each parallel tube is 7.5m3/h. The catalyst is of 0.006 meter diameter with density of 1500kg/m3. The void fraction of the catalyst packing is 30%. Pressure drop parameter, is given at 30kPa/m. Rate constant, k=6.84m3/( kgcat. h) at 600K. The rate law equation is given as rA=kCAO.5CBO.5 Calculate the total weight of catalyst necessary to achieve 85% conversion when the system operates isothermally at 600K

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts