Question: this is all one question, please answer all parts Assume we have a two-layer supply chain with two manufacturing companies of A and B that

this is all one question, please answer all parts

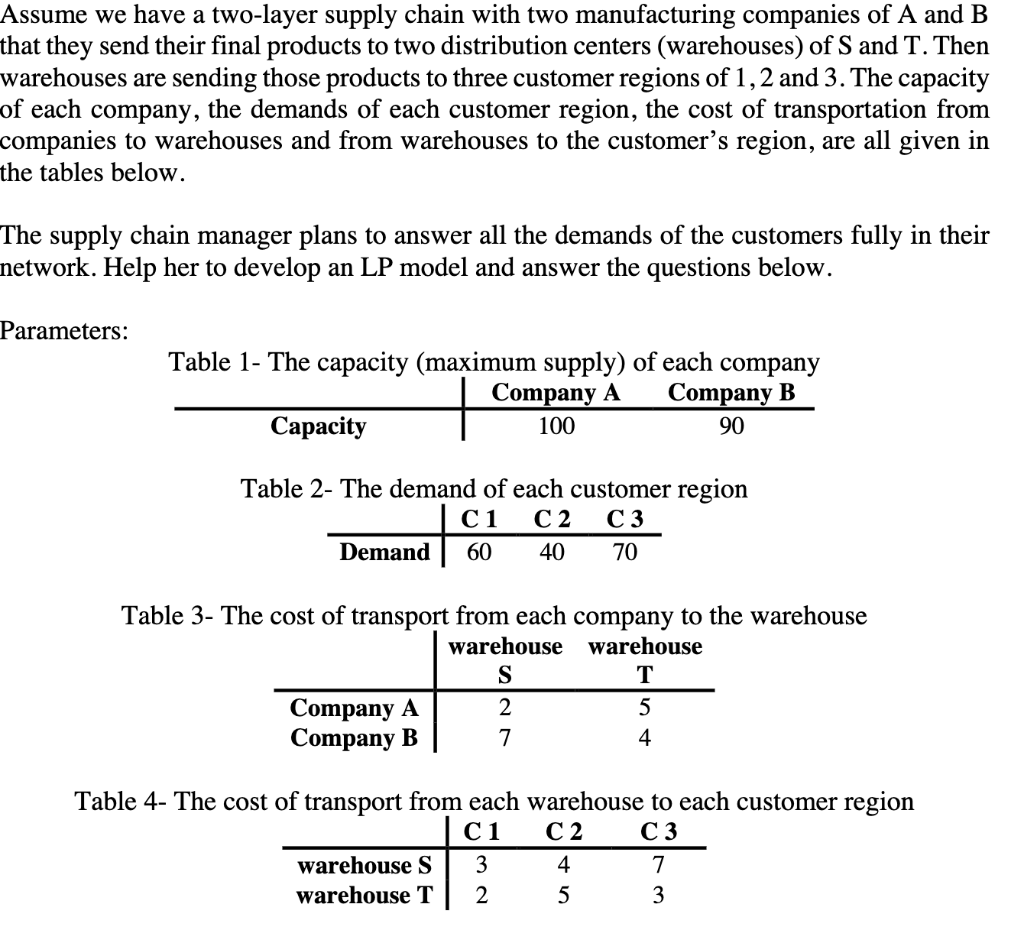

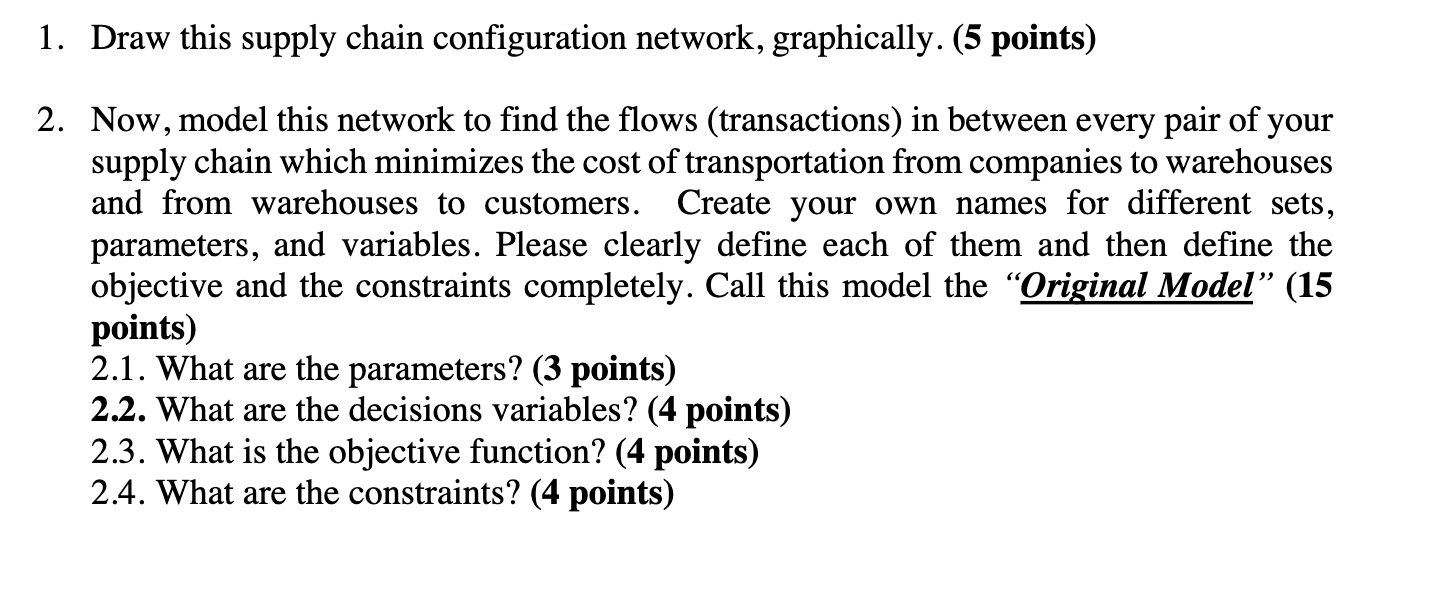

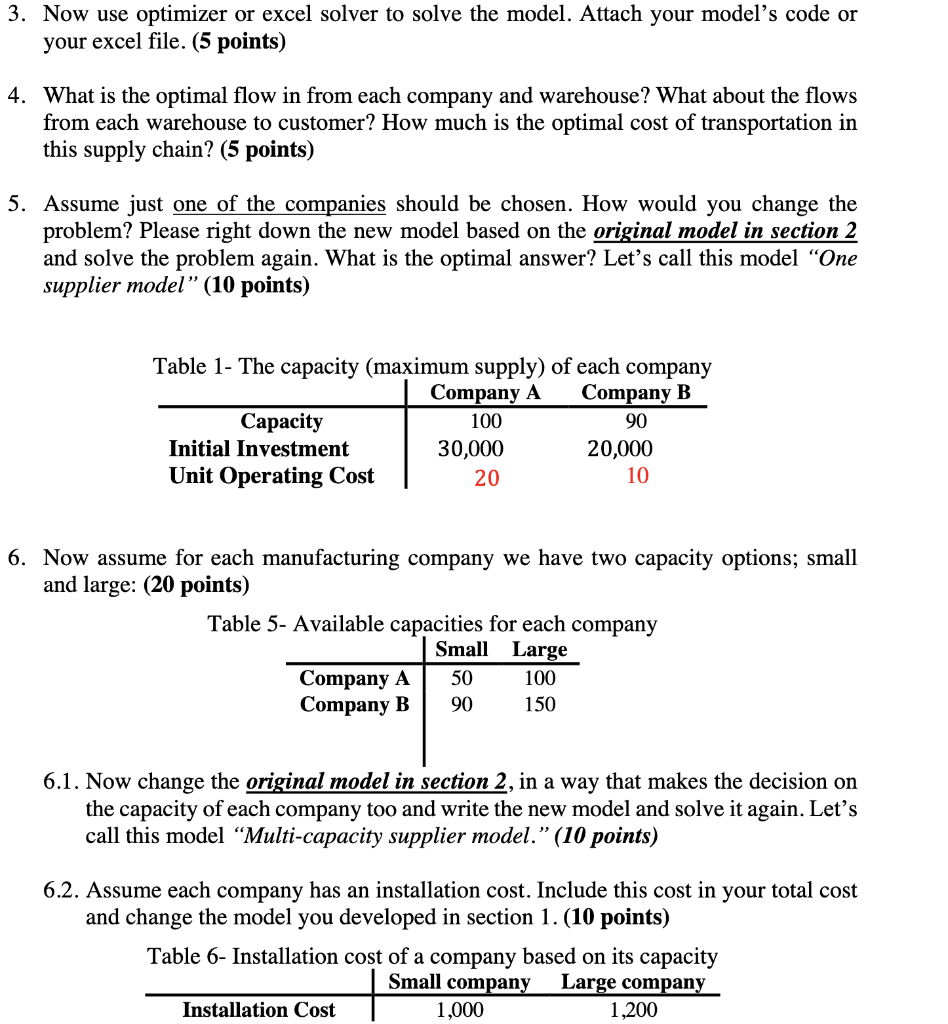

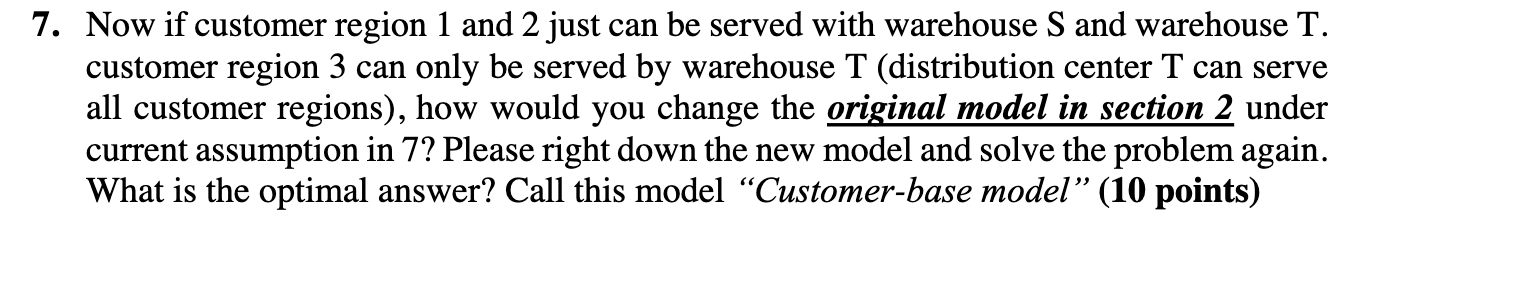

Assume we have a two-layer supply chain with two manufacturing companies of A and B that they send their final products to two distribution centers (warehouses) of S and T. Then warehouses are sending those products to three customer regions of 1, 2 and 3. The capacity of each company, the demands of each customer region, the cost of transportation from companies to warehouses and from warehouses to the customer's region, are all given in the tables below. The supply chain manager plans to answer all the demands of the customers fully in their network. Help her to develop an LP model and answer the questions below. Parameters: Table 1- The capacity (maximum supply) of each company Company A Company B Capacity 100 90 Table 2- The demand of each customer region C1 C2 C3 Demand 60 40 70 Table 3- The cost of transport from each company to the warehouse warehouse warehouse S T Company A 2 5 Company B 7 4 Table 4- The cost of transport from each warehouse to each customer region C1 C2 3 warehouse S 3 4 7 warehouse T 2 5 3 1. Draw this supply chain configuration network, graphically. (5 points) 2. Now, model this network to find the flows (transactions) in between every pair of your supply chain which minimizes the cost of transportation from companies to warehouses and from warehouses to customers. Create your own names for different sets, parameters, and variables. Please clearly define each of them and then define the objective and the constraints completely. Call this model the Original Model (15 points) 2.1. What are the parameters? (3 points) 2.2. What are the decisions variables? (4 points) 2.3. What is the objective function? (4 points) 2.4. What are the constraints? (4 points) 3. Now use optimizer or excel solver to solve the model. Attach your model's code or your excel file. (5 points) 4. What is the optimal flow in from each company and warehouse? What about the flows from each warehouse to customer? How much is the optimal cost of transportation in this supply chain? (5 points) 5. Assume just one of the companies should be chosen. How would you change the problem? Please right down the new model based on the original model in section 2 and solve the problem again. What is the optimal answer? Let's call this model "One supplier model (10 points) Table 1- The capacity (maximum supply) of each company Company A Company B Capacity 100 90 Initial Investment 30,000 20,000 Unit Operating Cost 20 10 6. Now assume for each manufacturing company we have two capacity options; small and large: (20 points) Table 5- Available capacities for each company Small Large Company A 100 Company B 90 150 6.1. Now change the original model in section 2, in a way that makes the decision on the capacity of each company too and write the new model and solve it again. Let's call this model Multi-capacity supplier model. (10 points) 6.2. Assume each company has an installation cost. Include this cost in your total cost and change the model you developed in section 1. (10 points) Table 6- Installation cost of a company based on its capacity Small company Large company Installation Cost 1,000 1,200 7. Now if customer region 1 and 2 just can be served with warehouse S and warehouse T. customer region 3 can only be served by warehouse T (distribution center T can serve all customer regions), how would you change the original model in section 2 under current assumption in 7? Please right down the new model and solve the problem again. What is the optimal answer? Call this model Customer-base model (10 points)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock