Question: this is all one question yes it is please zoom in because someone else just tried it but gave me all wrong answers. zoom in

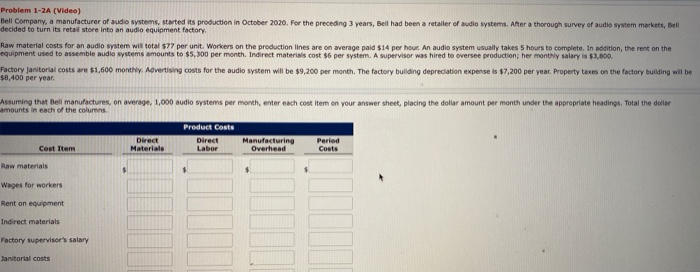

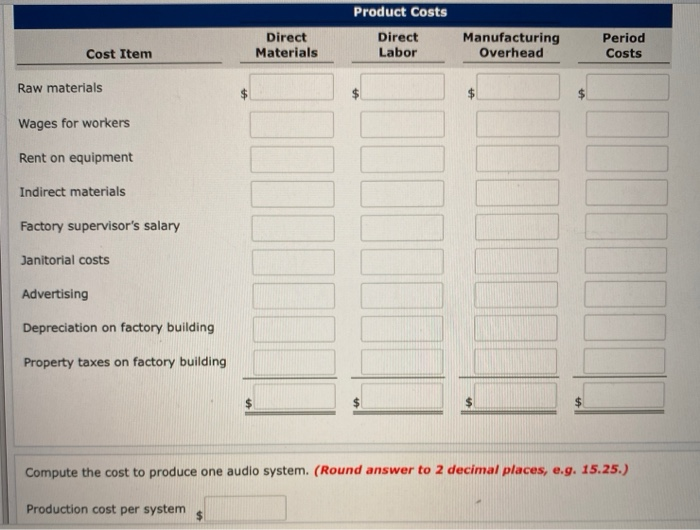

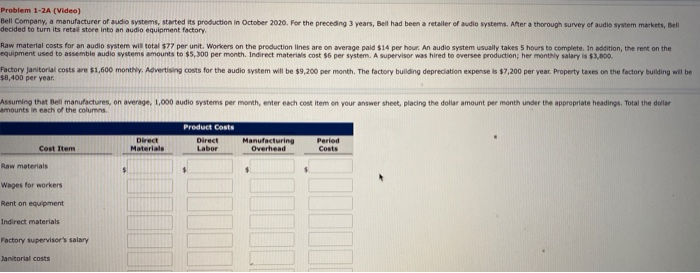

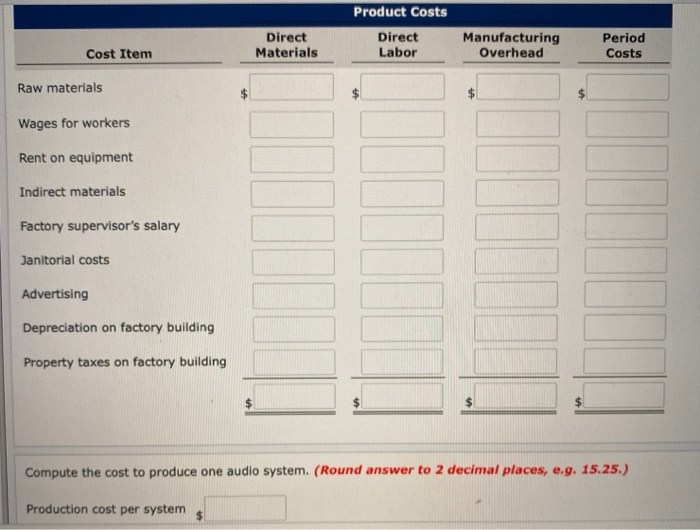

Problem 1-2A (Video) Bell Company, a manufacturer of audio systems, started its production in October 2020. For the preceding 3 years, Bell had been a retailer of audio systems. After a thorough survey of audio system markets, Bell decided to turn its retail store into an audio equipment factory Raw material costs for an audio system wil total 577 per unit. Workers on the production lines are on average paid $14 per hour. An audio system usually takes 5 hours to complete. In addition, the rent on the equipment used to assemble audio systems amounts to $5,300 per month. Indirect materials cost $6 per system. A supervisor was hired to oversee production, her monthly salary is $3,800 Factory Janitorial costs are $1,600 monthly Advertising costs for the audio system will be $9,200 per month. The factory building depreciation expense is $7,200 per year. Property taxes on the factory building will be $8,400 per year Assuming that Bell manufactures, on average, 1,000 audio systems per month, enter each cost item on your answer sheet, placing the dollar amount per month under the appropriate headings. Total the dollar amounts in each of the columns Product Costs Direct Labor Direct Materials Cost Item Manufacturing Overhead Period Costs Raw materials $ Wages for workers Rent on equipment Indirect materials Factory supervisor's salary Janitorial costs Product Costs Direct Materials Direct Labor Manufacturing Overhead Period Costs Cost Item Raw materials $ Wages for workers Rent on equipment Indirect materials Factory supervisor's salary Janitorial costs Advertising Depreciation on factory building Property taxes on factory building Compute the cost to produce one audio system. (Round answer to 2 decimal places, e.g. 15.25.) Production cost per system Problem 1-2A (Video) Bell Company, a manufacturer of audio systems, started its production in October 2020. For the preceding 3 years, Bell had been a retailer of audio systems. After a thorough survey of audio system markets, Bell decided to turn its retail store into an audio equipment factory Raw material costs for an audio system wil total 577 per unit. Workers on the production lines are on average paid $14 per hour. An audio system usually takes 5 hours to complete. In addition, the rent on the equipment used to assemble audio systems amounts to $5,300 per month. Indirect materials cost $6 per system. A supervisor was hired to oversee production, her monthly salary is $3,800 Factory Janitorial costs are $1,600 monthly Advertising costs for the audio system will be $9,200 per month. The factory building depreciation expense is $7,200 per year. Property taxes on the factory building will be $8,400 per year Assuming that Bell manufactures, on average, 1,000 audio systems per month, enter each cost item on your answer sheet, placing the dollar amount per month under the appropriate headings. Total the dollar amounts in each of the columns Product Costs Direct Labor Direct Materials Cost Item Manufacturing Overhead Period Costs Raw materials $ Wages for workers Rent on equipment Indirect materials Factory supervisor's salary Janitorial costs Product Costs Direct Materials Direct Labor Manufacturing Overhead Period Costs Cost Item Raw materials $ Wages for workers Rent on equipment Indirect materials Factory supervisor's salary Janitorial costs Advertising Depreciation on factory building Property taxes on factory building Compute the cost to produce one audio system. (Round answer to 2 decimal places, e.g. 15.25.) Production cost per system

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts