Question: this is the partial map it gives to start solution. . . Pacific Corporation produces plastic molded components for the home appliances Industry. The Information

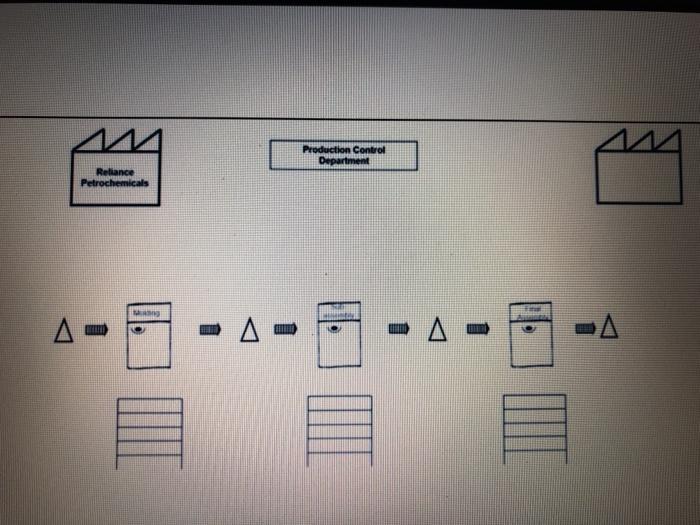

. . Pacific Corporation produces plastic molded components for the home appliances Industry. The Information presented here was collected by a team of students and is related to a value stream for producing a family of plastic moldings at Pacific Corporation. These components are shipped weekly by truck to an assembly plant owned by Jonson's Appliances Jonson's Appliances requires 12,600 pieces of molded components per month. Pacific's production control department receives 6-week sales forecasts by weekly e-mall from Jonson to help with production planning for specific requirements among the product family. Firm orders are received daily through an internet based system. The main raw material is ABS granules is purchased from Union Petrochemicals and delivered to the Pacific manufacturing facility once a week based on weekly orders placed by production control department. The Pacific manufacturing facility runs : 20 days per month, one shift per day. A shift is eight hours with one 30-minute and two-15 minute breaks in which work stops. The manufacturing process at Pacific is divided into three main processes: molding, sub-assembly and Final assembly. The production control department issues work orders every morning specifying the details to be completed in each of these three operations. During their walk through the facility, the lean team observed and computed based on weight that there were enough ABS granules in storage for 1,890 pcs of finished molds. There were two workstations with two employees working in parallel on molding, and molded sub-components required for 50 finished components were produced in one hour. The average set-up time for changing the settings on the molding is 75 min. There were enough sub components in inventory after the molding operation for 945 finished components. The sub-assembly task had one workstation with one employee who produced sub assemblies for 45 finished components in thirty minutes. The average set up time for replacing the fixtures and tools required for different types of mold and components is 25 min. There were 630 sub assemblies in inventory after this operation The final assembly task had 3 employees in three workstations. In 30 minutes, one employee had finished assembling and readying for shipment 4 boxes of 5 components each. There were 300 boxes, each consisting of five components of finished goods inventory, ready to be shipped to Jonson's company . . Prepare a value stream map based on the materials and information provided You can the next partial map to start your Solution M Production Control Department Reliance Petrochemicals LET um . . Pacific Corporation produces plastic molded components for the home appliances Industry. The Information presented here was collected by a team of students and is related to a value stream for producing a family of plastic moldings at Pacific Corporation. These components are shipped weekly by truck to an assembly plant owned by Jonson's Appliances Jonson's Appliances requires 12,600 pieces of molded components per month. Pacific's production control department receives 6-week sales forecasts by weekly e-mall from Jonson to help with production planning for specific requirements among the product family. Firm orders are received daily through an internet based system. The main raw material is ABS granules is purchased from Union Petrochemicals and delivered to the Pacific manufacturing facility once a week based on weekly orders placed by production control department. The Pacific manufacturing facility runs : 20 days per month, one shift per day. A shift is eight hours with one 30-minute and two-15 minute breaks in which work stops. The manufacturing process at Pacific is divided into three main processes: molding, sub-assembly and Final assembly. The production control department issues work orders every morning specifying the details to be completed in each of these three operations. During their walk through the facility, the lean team observed and computed based on weight that there were enough ABS granules in storage for 1,890 pcs of finished molds. There were two workstations with two employees working in parallel on molding, and molded sub-components required for 50 finished components were produced in one hour. The average set-up time for changing the settings on the molding is 75 min. There were enough sub components in inventory after the molding operation for 945 finished components. The sub-assembly task had one workstation with one employee who produced sub assemblies for 45 finished components in thirty minutes. The average set up time for replacing the fixtures and tools required for different types of mold and components is 25 min. There were 630 sub assemblies in inventory after this operation The final assembly task had 3 employees in three workstations. In 30 minutes, one employee had finished assembling and readying for shipment 4 boxes of 5 components each. There were 300 boxes, each consisting of five components of finished goods inventory, ready to be shipped to Jonson's company . . Prepare a value stream map based on the materials and information provided You can the next partial map to start your Solution M Production Control Department Reliance Petrochemicals LET um

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts