Question: This question will have you calculating 2 EOQ and ROP values and interpreting the results. For both EOQ and ROP, give your final answer in

- This question will have you calculating 2 EOQ and ROP values and interpreting the results. For both EOQ and ROP, give your final answer in full sock sets (ROUND UP to the next whole number). The specific questions to answer are based in parts a-c. Tips to solve the EOQ and ROP are given below in bullet points.

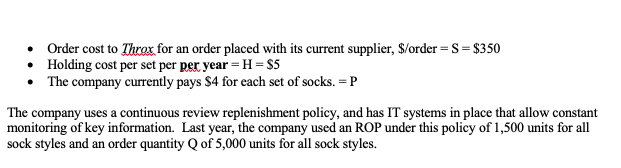

- Calculate EOQ and ROP for FY2017 based on the Exponential Forecast .

- Calculate the EOQ and ROP based upon actual demand for FY2017

- Using the responses from parts a & b, indicate what the implications are for inventory management costs in FY2017. In other words, 1. Compare the total costs for both EOQ values and analyze what it shows you. 2. What if any are the implications of the ROP based on the forecast vs the ROP based on actual demand.

See additional tips below:

- Use a service level of 95% (z=1.65) when calculating the ROP

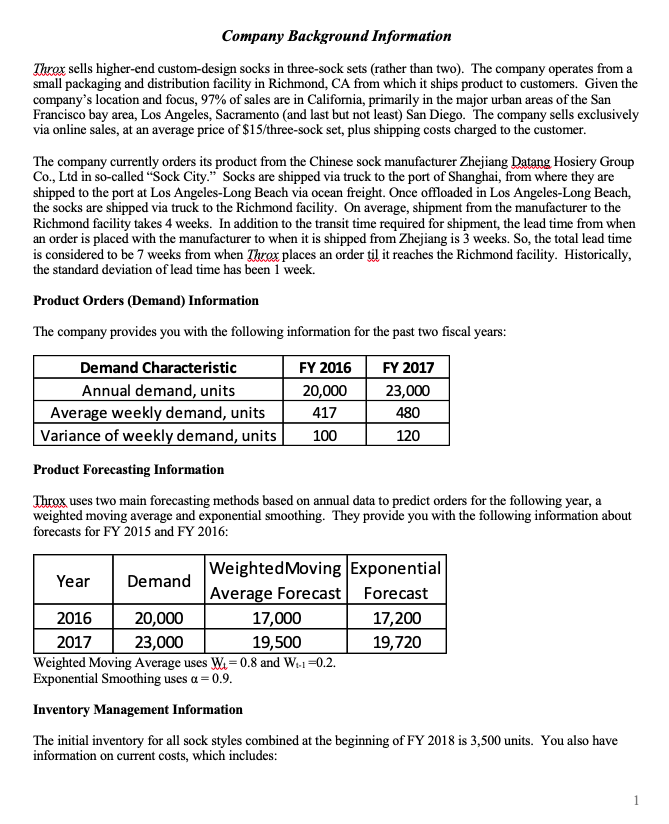

- Calculate average weekly demand (d ) by dividing the forecast by 50 weeks

- For the variance in weekly demand, use the data provided in the table on page 2 of the case with the FY2017 forecast for all approaches.

- Remember that there is a difference between variance and standard deviation and how you apply these values in the ROP formula

- Annual Inventory management costs will include the following: Annual Holding Costs, Annual Ordering Costs, and Purchase Cost.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock