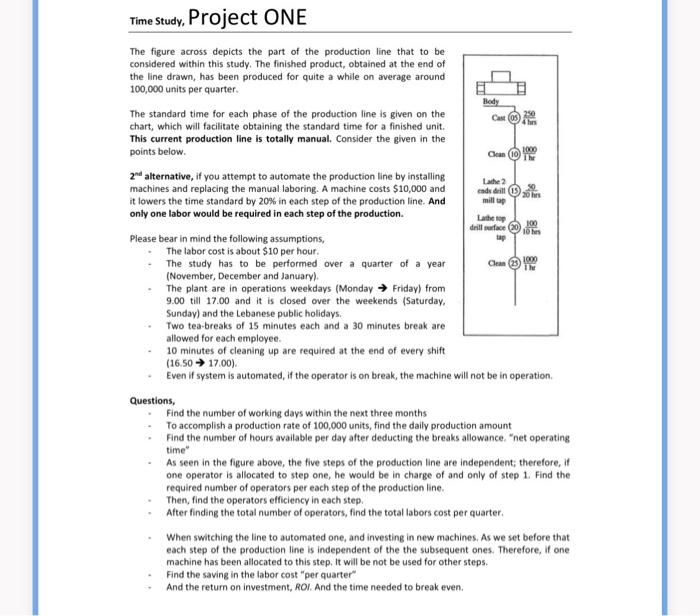

Question: Time Study, Project ONE Body Case 58 Cea 10 1000 will drill face 10 hrs The figure across depicts the part of the production line

Time Study, Project ONE Body Case 58 Cea 10 1000 will drill face 10 hrs The figure across depicts the part of the production line that to be considered within this study. The finished product, obtained at the end of the line drawn, has been produced for quite a while on average around 100,000 units per quarter The standard time for each phase of the production line is given on the chart, which will facilitate obtaining the standard time for a finished unit. This current production line is totally manual. Consider the given in the points below. 2nd alternative, if you attempt to automate the production line by installing Lathe 2 machines and replacing the manual laboring. A machine costs $10,000 and ende drill (15) it lowers the time standard by 20% in each step of the production line. And only one labor would be required in each step of the production 100 Please bear in mind the following assumptions, The labor cost is about $10 per hour. The study has to be performed over a quarter of a year Clean 1000 (November, December and January). The plant are in operations weekdays (Monday Friday) from 9.00 till 17.00 and it is closed over the weekends (Saturday, Sunday) and the Lebanese public holidays. Two tea-breaks of 15 minutes each and a 30 minutes break are allowed for each employee 10 minutes of cleaning up are required at the end of every shift (16.50 17.00) Even if system is automated, if the operator is on break, the machine will not be in operation Questions, Find the number of working days within the next three months To accomplish a production rate of 100,000 units, find the daily production amount Find the number of hours available per day after deducting the breaks allowance. "net operating time" As seen in the figure above, the five steps of the production line are independent; therefore, if one operator is allocated to step one, he would be in charge of and only of step 1. Find the required number of operators per each step of the production line Then, find the operators efficiency in each step. After finding the total number of operators, find the total labors cost per quarter. When switching the line to automated one, and investing in new machines. As we set before that each step of the production line is independent of the the subsequent ones. Therefore, If one machine has been allocated to this step. It will be not be used for other steps. Find the saving in the labor cost "per quarter" And the return on investment, ROI. And the time needed to break even. Time Study, Project ONE Body Case 58 Cea 10 1000 will drill face 10 hrs The figure across depicts the part of the production line that to be considered within this study. The finished product, obtained at the end of the line drawn, has been produced for quite a while on average around 100,000 units per quarter The standard time for each phase of the production line is given on the chart, which will facilitate obtaining the standard time for a finished unit. This current production line is totally manual. Consider the given in the points below. 2nd alternative, if you attempt to automate the production line by installing Lathe 2 machines and replacing the manual laboring. A machine costs $10,000 and ende drill (15) it lowers the time standard by 20% in each step of the production line. And only one labor would be required in each step of the production 100 Please bear in mind the following assumptions, The labor cost is about $10 per hour. The study has to be performed over a quarter of a year Clean 1000 (November, December and January). The plant are in operations weekdays (Monday Friday) from 9.00 till 17.00 and it is closed over the weekends (Saturday, Sunday) and the Lebanese public holidays. Two tea-breaks of 15 minutes each and a 30 minutes break are allowed for each employee 10 minutes of cleaning up are required at the end of every shift (16.50 17.00) Even if system is automated, if the operator is on break, the machine will not be in operation Questions, Find the number of working days within the next three months To accomplish a production rate of 100,000 units, find the daily production amount Find the number of hours available per day after deducting the breaks allowance. "net operating time" As seen in the figure above, the five steps of the production line are independent; therefore, if one operator is allocated to step one, he would be in charge of and only of step 1. Find the required number of operators per each step of the production line Then, find the operators efficiency in each step. After finding the total number of operators, find the total labors cost per quarter. When switching the line to automated one, and investing in new machines. As we set before that each step of the production line is independent of the the subsequent ones. Therefore, If one machine has been allocated to this step. It will be not be used for other steps. Find the saving in the labor cost "per quarter" And the return on investment, ROI. And the time needed to break even