Question: tou dont need to use solver for this problem An equipment manufacturer is developing a production schedule for the next five months (say May -

tou dont need to use solver for this problem

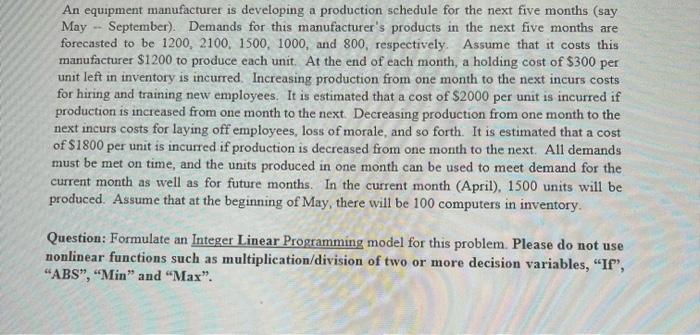

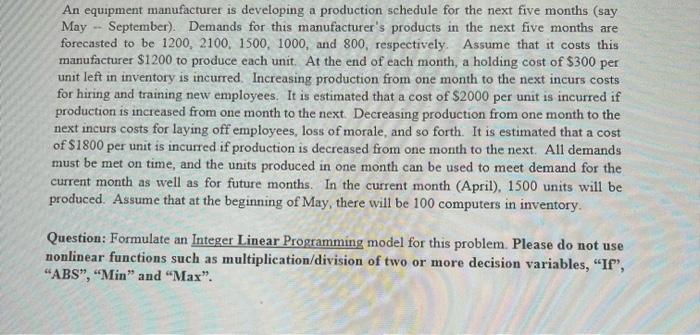

An equipment manufacturer is developing a production schedule for the next five months (say May - September). Demands for this manufacturer's products in the next five months are forecasted to be 1200,2100,1500,1000, and 800 , respectively. Assume that it costs this manufacturer $1200 to produce each unit. At the end of each month, a holding cost of $300 per unit left in inventory is incurred. Increasing production from one month to the next incurs costs for hiring and training new employees. It is estimated that a cost of $2000 per unit is incurred if production is increased from one month to the next. Decreasing production from one month to the next incurs costs for laying off employees, loss of morale, and so forth. It is estimated that a cost of $1800 per unit is incurred if production is decreased from one month to the next. All demands must be met on time, and the units produced in one month can be used to meet demand for the current month as well as for future months. In the current month (April), 1500 units will be produced. Assume that at the beginning of May, there will be 100 computers in inventory. Question: Formulate an Integer Linear Programming model for this problem. Please do not use nonlinear functions such as multiplication/division of two or more decision variables, "If", "ABS", "Min" and "Max

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock