Question: Two metal sheets are subjected to cold rolling. Both sheets have identical chemical composition, and started with the same initial thickness prior to cold rolling

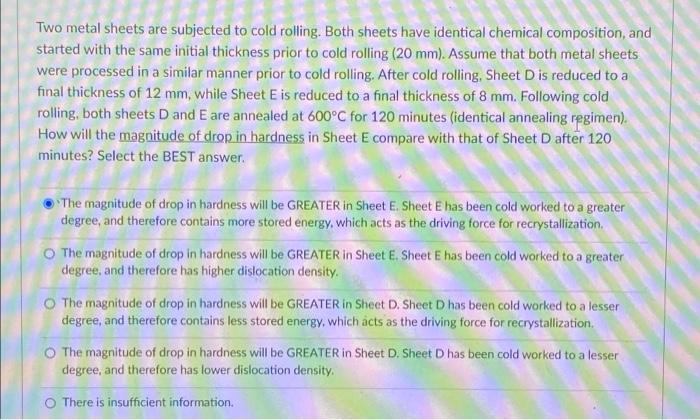

Two metal sheets are subjected to cold rolling. Both sheets have identical chemical composition, and started with the same initial thickness prior to cold rolling (20 mm). Assume that both metal sheets were processed in a similar manner prior to cold rolling, After cold rolling, Sheet D is reduced to a final thickness of 12 mm, while Sheet E is reduced to a final thickness of 8 mm. Following cold rolling, both sheets D and E are annealed at 600C for 120 minutes (identical annealing regimen). How will the magnitude of drop in hardness in Sheet E compare with that of Sheet D after 120 minutes? Select the BEST answer The magnitude of drop in hardness will be GREATER in Sheet E. Sheet E has been cold worked to a greater degree, and therefore contains more stored energy, which acts as the driving force for recrystallization, The magnitude of drop in hardness will be GREATER in Sheet E. Sheet E has been cold worked to a greater degree, and therefore has higher dislocation density. The magnitude of drop in hardness will be GREATER in Sheet D. Sheet D has been cold worked to a lesser degree, and therefore contains less stored energy, which acts as the driving force for recrystallization The magnitude of drop in hardness will be GREATER in Sheet D. Sheet D has been cold worked to a lesser degree, and therefore has lower dislocation density There is insufficient information

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts