Question: Type or paste question here Ken Mack, plant manager for the AOne Company, was having a heated discussion with Jim Gould, the production and inventory

Type or paste question here

Type or paste question here

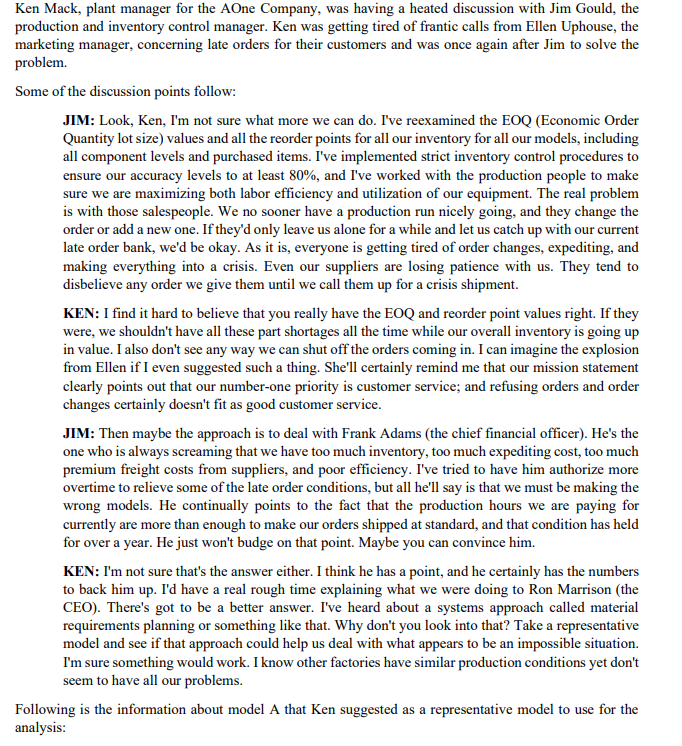

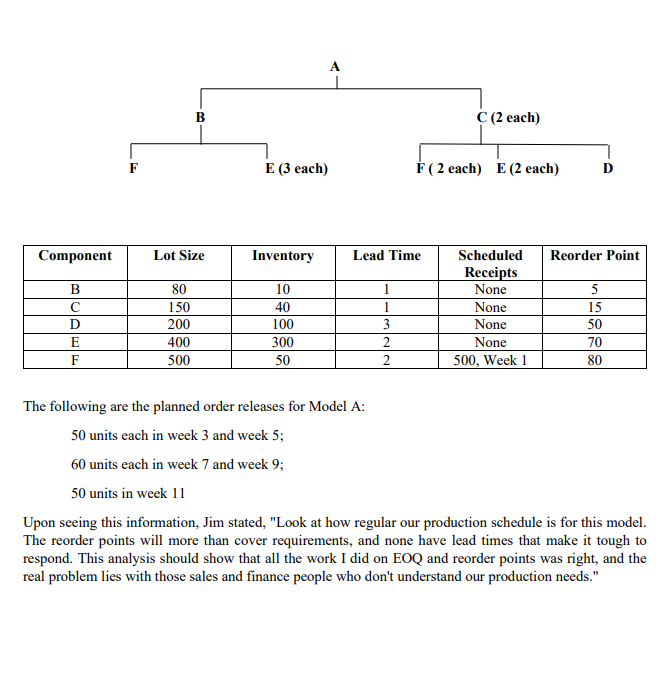

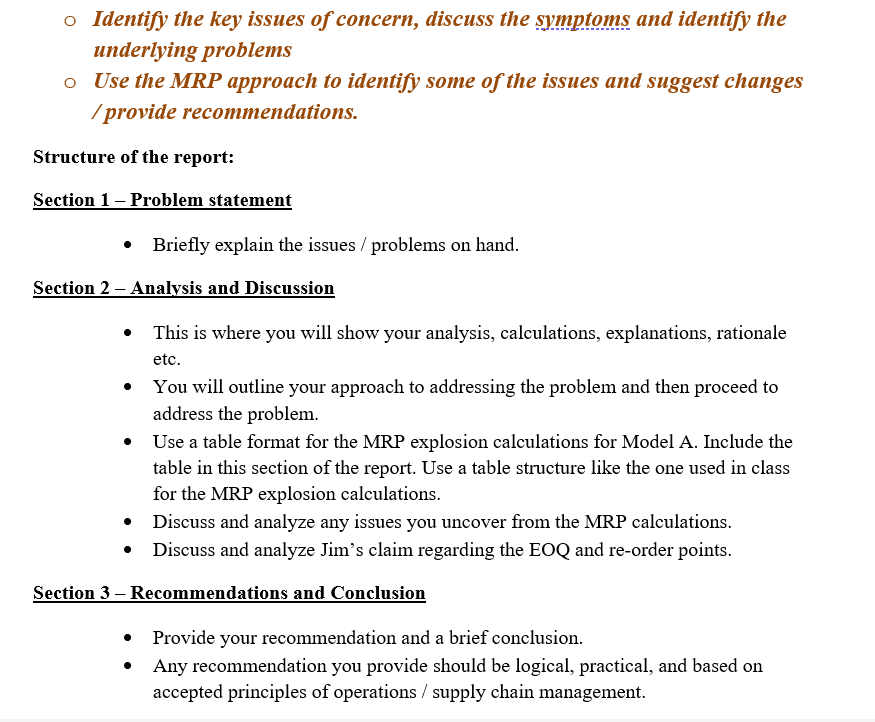

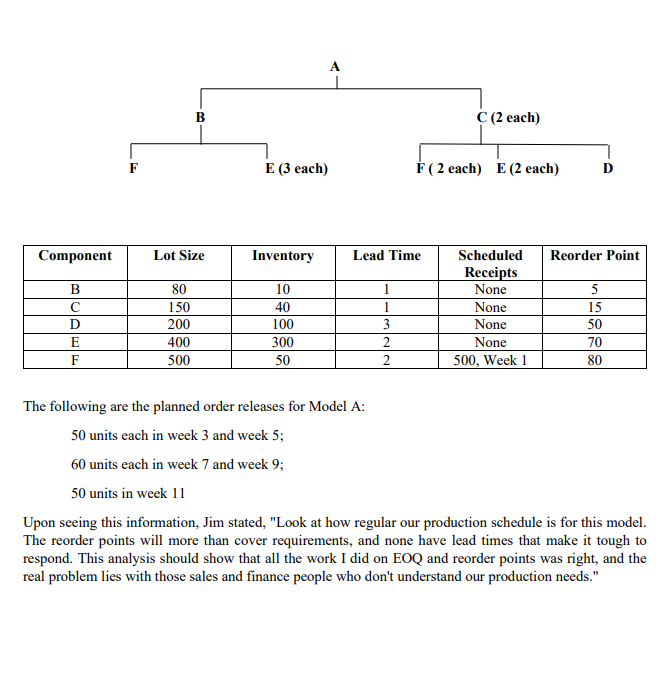

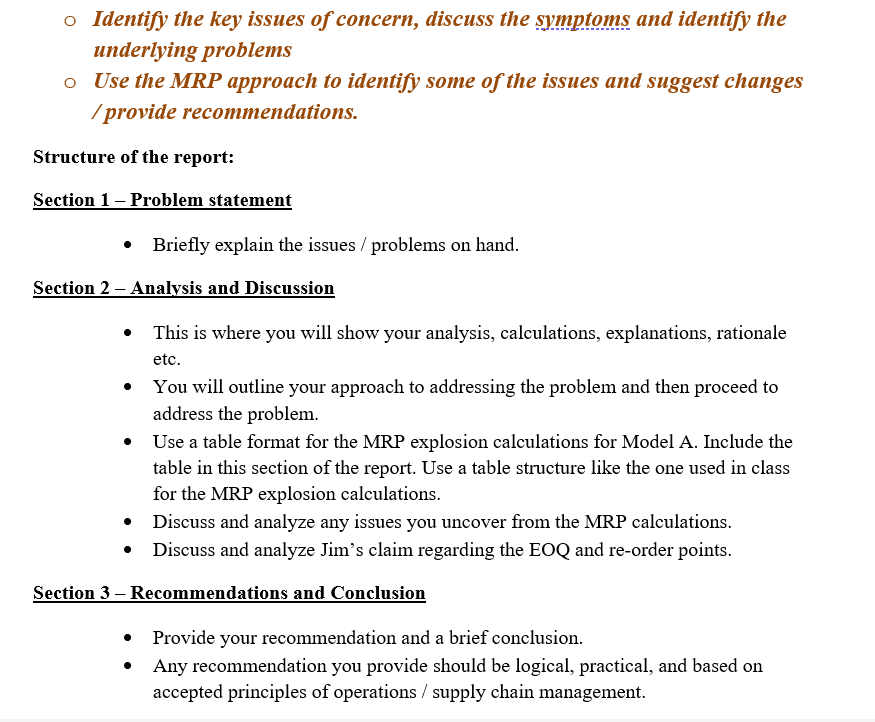

Ken Mack, plant manager for the AOne Company, was having a heated discussion with Jim Gould, the production and inventory control manager. Ken was getting tired of frantic calls from Ellen Uphouse, the marketing manager, concerning late orders for their customers and was once again after Jim to solve the problem. Some of the discussion points follow: JIM: Look, Ken, I'm not sure what more we can do. I've reexamined the EOQ (Economic Order Quantity lot size) values and all the reorder points for all our inventory for all our models, including all component levels and purchased items. I've implemented strict inventory control procedures to ensure our accuracy levels to at least 80%, and I've worked with the production people to make sure we are maximizing both labor efficiency and utilization of our equipment. The real problem is with those salespeople. We no sooner have a production run nicely going, and they change the order or add a new one. If they'd only leave us alone for a while and let us catch up with our current late order bank, we'd be okay. As it is, everyone is getting tired of order changes, expediting, and making everything into a crisis. Even our suppliers are losing patience with us. They tend to disbelieve any order we give them until we call them up for a crisis shipment. KEN: I find it hard to believe that you really have the EOQ and reorder point values right. If they were, we shouldn't have all these part shortages all the time while our overall inventory is going up in value. I also don't see any way we can shut off the orders coming in. I can imagine the explosion from Ellen if I even suggested such a thing. She'll certainly remind me that our mission statement clearly points out that our number-one priority is customer service, and refusing orders and order changes certainly doesn't fit as good customer service. JIM: Then maybe the approach is to deal with Frank Adams (the chief financial officer). He's the one who is always screaming that we have too much inventory, too much expediting cost, too much premium freight costs from suppliers, and poor efficiency. I've tried to have him authorize more overtime to relieve some of the late order conditions, but all he'll say is that we must be making the wrong models. He continually points to the fact that the production hours we are paying for currently are more than enough to make our orders shipped at standard, and that condition has held for over a year. He just won't budge on that point. Maybe you can convince him. KEN: I'm not sure that's the answer either. I think he has a point, and he certainly has the numbers to back him up. I'd have a real rough time explaining what we were doing to Ron Marrison (the CEO). There's got to be a better answer. I've heard about a systems approach called material requirements planning or something like that. Why don't you look into that? Take a representative model and see if that approach could help us deal with what appears to be an impossible situation. I'm sure something would work. I know other factories have similar production conditions yet don't seem to have all our problems. Following is the information about model A that Ken suggested as a representative model to use for the analysis: A B C (2 each) F E (3 each) (2 each) E (2 each) D Component Lot Size Inventory Lead Time Reorder Point 1 B D E F 80 150 200 400 500 10 40 100 300 50 Scheduled Receipts None None None None 500, Week 1 3 2 2 5 15 50 70 80 The following are the planned order releases for Model A: 50 units each in week 3 and week 5; 60 units each in week 7 and week 9; 50 units in week 11 Upon seeing this information, Jim stated, "Look at how regular our production schedule is for this model. The reorder points will more than cover requirements, and none have lead times that make it tough to respond. This analysis should show that all the work I did on EOQ and reorder points was right, and the real problem lies with those sales and finance people who don't understand our production needs." o Identify the key issues of concern, discuss the symptoms and identify the underlying problems o Use the MRP approach to identify some of the issues and suggest changes /provide recommendations. Structure of the report: Section 1 - Problem statement Briefly explain the issues / problems on hand. Section 2 Analysis and Discussion . This is where you will show your analysis, calculations, explanations, rationale etc. You will outline your approach to addressing the problem and then proceed to address the problem. Use a table format for the MRP explosion calculations for Model A. Include the table in this section of the report. Use a table structure like the one used in class for the MRP explosion calculations. Discuss and analyze any issues you uncover from the MRP calculations. Discuss and analyze Jim's claim regarding the EOQ and re-order points. Section 3 Recommendations and Conclusion Provide your recommendation and a brief conclusion. Any recommendation you provide should be logical, practical, and based on accepted principles of operations / supply chain management

Type or paste question here

Type or paste question here