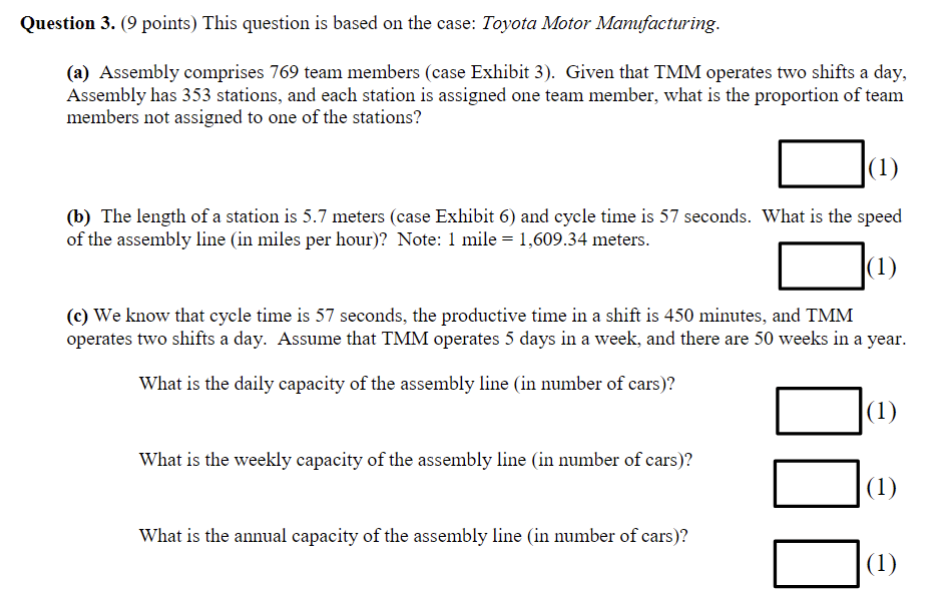

Question: uestion 3. (9 points) This question is based on the case: Toyota Motor Manufacturing. (a) Assembly comprises 769 team members (case Exhibit 3). Given that

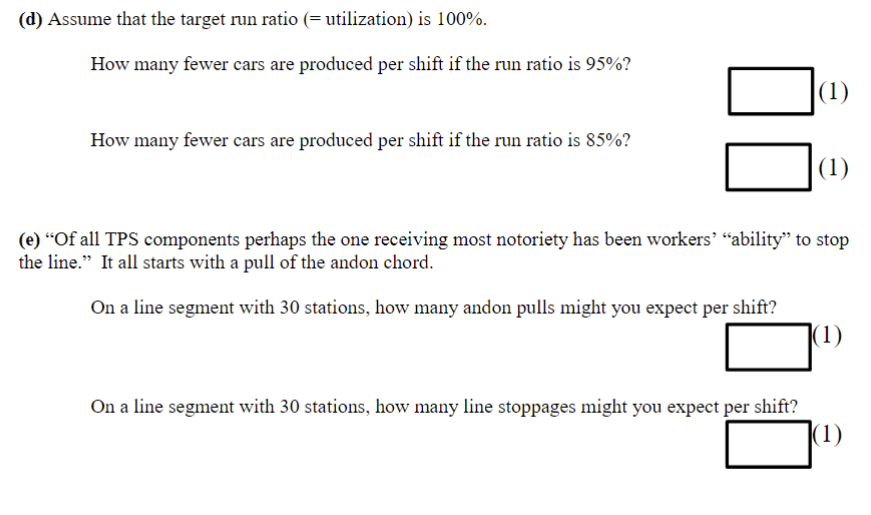

uestion 3. (9 points) This question is based on the case: Toyota Motor Manufacturing. (a) Assembly comprises 769 team members (case Exhibit 3). Given that TMM operates two shifts a day, Assembly has 353 stations, and each station is assigned one team member, what is the proportion of team members not assigned to one of the stations? (b) The length of a station is 5.7 meters (case Exhibit 6) and cycle time is 57 seconds. What is the speed of the assembly line (in miles per hour)? Note: 1 mile =1,609.34 meters. (c) We know that cycle time is 57 seconds, the productive time in a shift is 450 minutes, and TMM operates two shifts a day. Assume that TMM operates 5 days in a week, and there are 50 weeks in a year. What is the daily capacity of the assembly line (in number of cars)? What is the weekly capacity of the assembly line (in number of cars)? What is the annual capacity of the assembly line (in number of cars)? (d) Assume that the target run ratio (= utilization) is 100%. How many fewer cars are produced per shift if the run ratio is 95% ? How many fewer cars are produced per shift if the run ratio is 85% ? (e) "Of all TPS components perhaps the one receiving most notoriety has been workers' "ability" to stop the line." It all starts with a pull of the andon chord. On a line segment with 30 stations, how many andon pulls might you expect per shift? (1) On a line segment with 30 stations, how many line stoppages might you expect per shift

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts