Question: undefined Consider the spreadsheet for Stone Age Surfboards provided below. Use this data to answer the following question(s), using the Standard Solver. Stone Age Surfboards

undefined

undefined

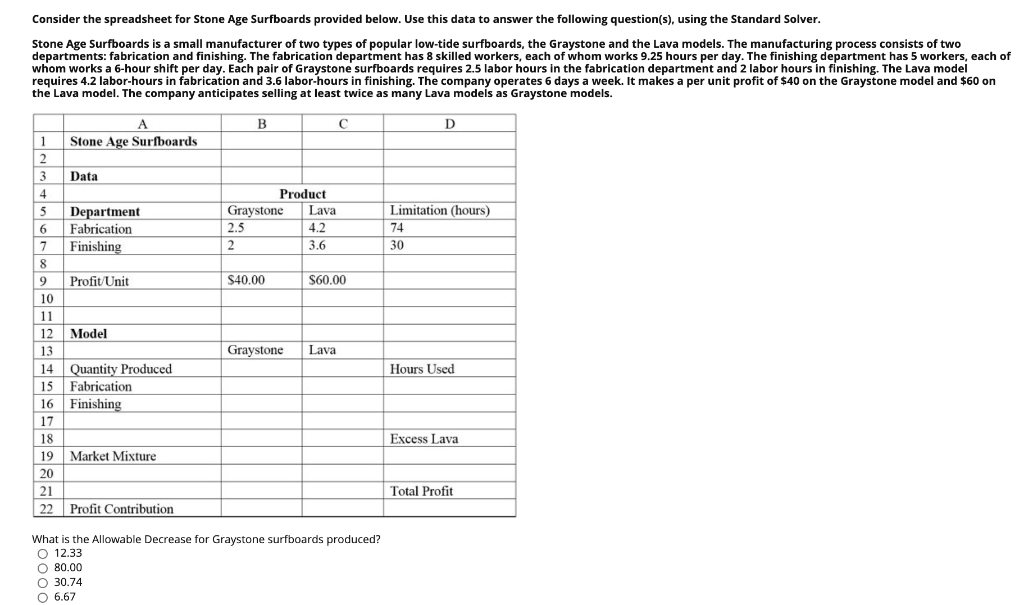

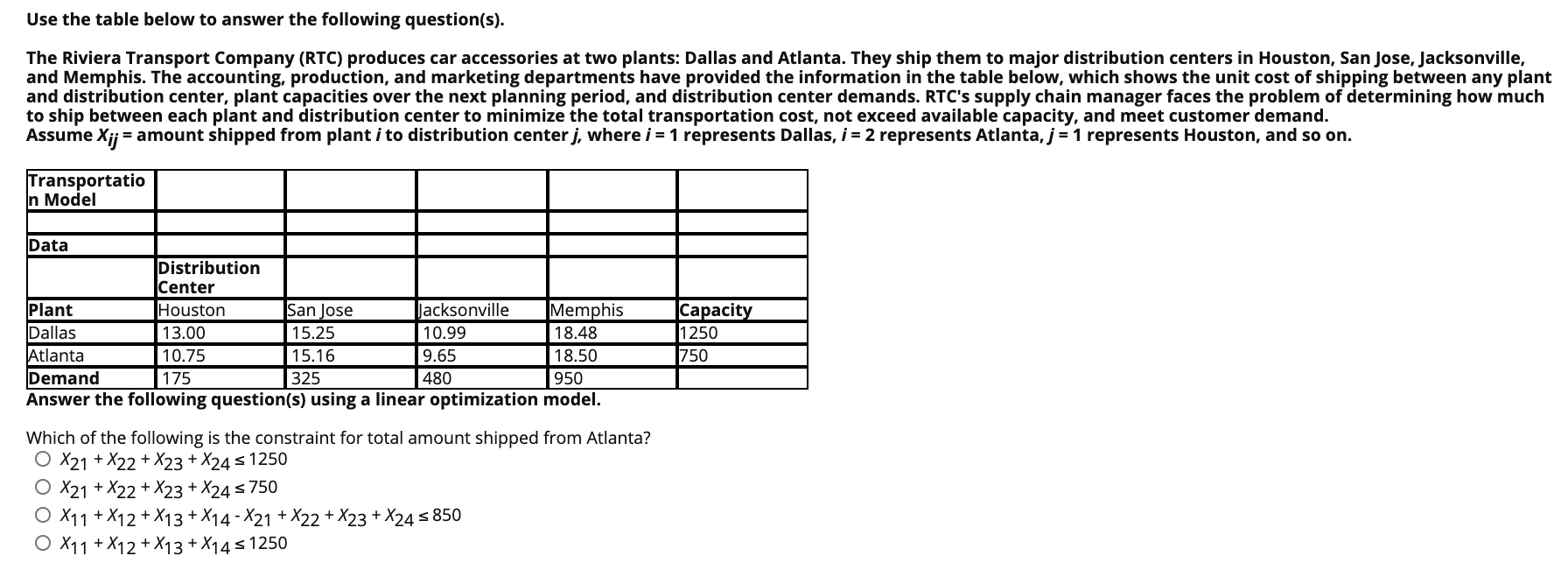

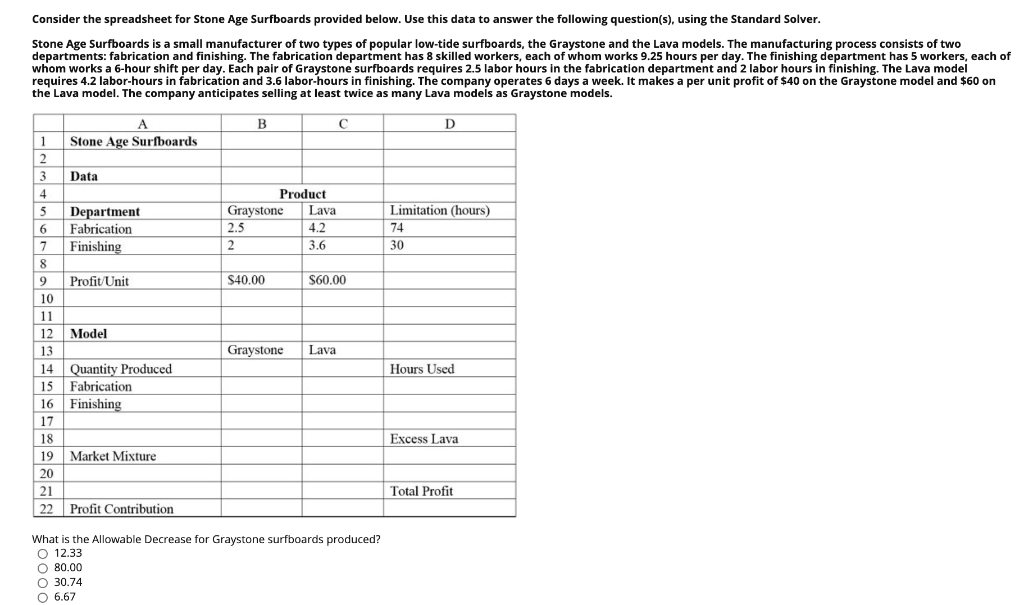

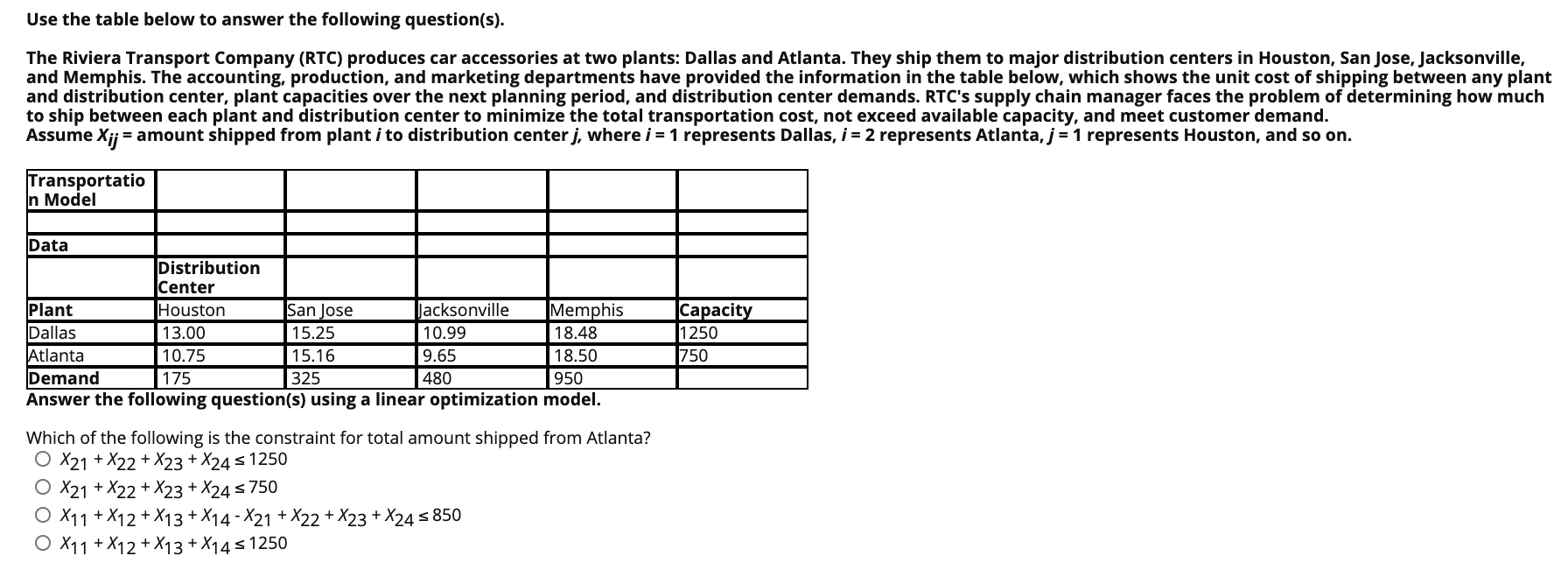

Consider the spreadsheet for Stone Age Surfboards provided below. Use this data to answer the following question(s), using the Standard Solver. Stone Age Surfboards is a small manufacturer of two types of popular low-tide surfboards, the Graystone and the Lava models. The manufacturing process consists of two departments: fabrication and finishing. The fabrication department has 8 skilled workers, each of whom works 9.25 hours per day. The finishing department has 5 workers, each of whom works a 6-hour shift per day. Each pair of Graystone surfboards requires 2.5 labor hours in the fabrication department and 2 labor hours in finishing. The Lava model requires 4.2 labor-hours in fabrication and 3.6 labor-hours in finishing. The company operates 6 days a week. It makes a per unit profit of $40 on the Graystone model and $60 on the Lava model. The company anticipates selling at least twice as many Lava models as Graystone models. B D Product Graystone Lava 2.5 4.2 2 3.6 Limitation (hours) 74 30 $40.00 $60.00 A 1 Stone Age Surfboards 2 3 Data 4 5 Department 6 Fabrication 7 Finishing 8 9 Profit/Unit 10 11 12 Model 13 14 Quantity Produced 15 Fabrication 16 Finishing 17 18 19 Market Mixture 20 21 22 Profit Contribution Graystone Lava Hours Used Excess Lava Total Profit What is the Allowable Decrease for Graystone surfboards produced? O 12.33 O 80.00 O 30.74 O 6.67 Use the table below to answer the following question(s). The Riviera Transport Company (RTC) produces car accessories at two plants: Dallas and Atlanta. They ship them to major distribution centers in Houston, San Jose, Jacksonville, and Memphis. The accounting, production, and marketing departments have provided the information in the table below, which shows the unit cost of shipping between any plant and distribution center, plant capacities over the next planning period, and distribution center demands. RTC's supply chain manager faces the problem of determining how much to ship between each plant and distribution center to minimize the total transportation cost, not exceed available capacity, and meet customer demand. Assume Xij = amount shipped from plant i to distribution center j, where i = 1 represents Dallas, i = 2 represents Atlanta, j= 1 represents Houston, and so on. Transportatio In Model Data Distribution Center Plant Houston San Jose Jacksonville Memphis Dallas 13.00 15.25 10.99 18.48 Atlanta 10.75 15.16 9.65 18.50 Demand 175 325 480 950 Answer the following question(s) using a linear optimization model. Capacity 1250 750 Which of the following is the constraint for total amount shipped from Atlanta? O X21 + X22 + X23 + X24 s 1250 O X21 + X22 + X23 + X24 s 750 O X11 +X12 + X13+X14 - X21 + X22 + X23 + X24 s 850 O X11 + X12 + X13 + X14 s 1250

undefined

undefined