Question: Update the LP in the case study Falcon Die Casting by extending the problem to multi-period problem. a) Write the new LP formulation for the

Update the LP in the case study Falcon Die Casting by extending the problem to multi-period problem.

a) Write the new LP formulation for the multi-period problem.

b) Solve the new LP using CPLEX based on the demand values on Table 1. Upload model and data files as well as the optimal results as a table. For this part, just use the following demand for Week 11: [3500 4000 4000 4000 3800]

c) Solve the new LP using CPLEX for original demand values (Table 1). Observe the problem is infeasible. As the lead person in this project, suggest some recommendations to solve this issue and apply your recommendations.

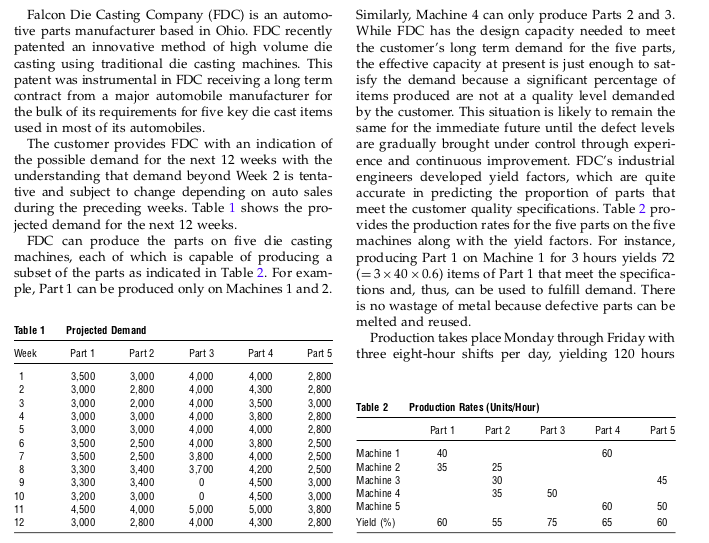

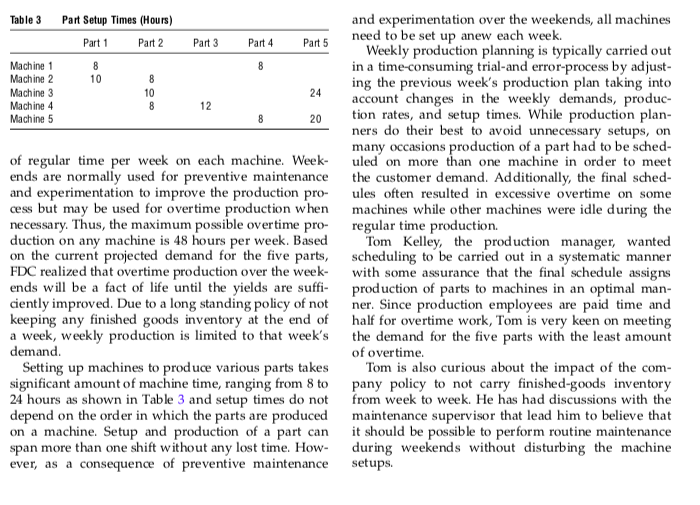

Falcon Die Casting Company (FDC) is an automo- Similarly, Machine 4 can only produce Parts 2 and 3. tive parts manufacturer based in Ohio. FDC recently While FDC has the design capacity needed to meet patented an innovative method of high volume die the customer's long term demand for the five parts, casting using traditional die casting machines. This the effective capacity at present is just enough to sat- patent was instrumental in FDC receiving a long term isfy the demand because a significant percentage of contract from a major automobile manufacturer for items produced are not at a quality level demanded the bulk of its requirements for five key die cast items by the customer. This situation is likely to remain the used in most of its automobiles. same for the immediate future until the defect levels The customer provides FDC with an indication of are gradually brought under control through experi- the possible demand for the next 12 weeks with the ence and continuous improvement. FDC's industrial understanding that demand beyond Week 2 is tenta- engineers developed yield factors, which are quite tive and subject to change depending on auto sales accurate in predicting the proportion of parts that during the preceding weeks. Table 1 shows the pro- meet the customer quality specifications. Table 2 pro- jected demand for the next 12 weeks. vides the production rates for the five parts on the five FDC can produce the parts on five die casting machines along with the yield factors. For instance, machines, each of which is capable of producing a producing Part 1 on Machine 1 for 3 hours yields 72 subset of the parts as indicated in Table 2. For exam- (=3 x 40 x 0.6) items of Part 1 that meet the specifica- ple, Part 1 can be produced only on Machines 1 and 2. tions and, thus, can be used to fulfill demand. There is no wastage of metal because defective parts can be melted and reused. Table 1 Projected Demand Production takes place Monday through Friday with Part 1 Part 2 Part 3 Part 5 three eight-hour shifts per day, yielding 120 hours 3,500 3,000 4,000 4,000 2,800 3,000 2,800 4,000 4,300 2,800 3,000 2,000 4,000 3,500 3,000 Production Rates (Units/Hour) 3,000 3,000 4,000 3,800 2,800 3,000 3,000 4,000 4,000 2,800 Part 1 Part 2 Part 3 Part 4 Part 5 3,500 2,500 4,000 3,800 2,500 7 3,500 2,500 3,800 4,000 2,500 Machine 1 3,300 3,400 3,700 4,200 2,500 Machine 2 3,300 3,400 4,500 3,000 Machine 3 30 3,200 3,000 4,500 3,000 11 4,500 4,000 5,000 5,000 3,800 3,000 2,800 4,000 4,300 2,800 Yield (%) 55 60 Week Part 4 1 Table 2 O VON 6 60 40 35 8 25 45 0 0 10 35 50 Machine 4 Machine 5 50 60 65 12 60 75 Part 3 Part 4 Part 5 8 8 10 8 10 8 24 Machine 4 12 8 20 Table 3 Part Setup Times (Hours) and experimentation over the weekends, all machines Part 1 Part 2 need to be set up anew each week. Weekly production planning is typically carried out Machine 1 in a time-consuming trial and error-process by adjust- Machine 2 ing the previous week's production plan taking into Machine 3 account changes in the weekly demands, produc- Machine 5 tion rates, and setup times. While production plan- ners do their best to avoid unnecessary setups, on many occasions production of a part had to be sched- of regular time per week on each machine. Week- uled on more than one machine in order to meet ends are normally used for preventive maintenance the customer demand. Additionally, the final sched- and experimentation to improve the production pro- ules often resulted in excessive overtime on some cess but may be used for overtime production when machines while other machines were idle during the necessary. Thus, the maximum possible overtime pro- regular time production. duction on any machine is 48 hours per week. Based Tom Kelley, the production manager, wanted on the current projected demand for the five parts, scheduling to be carried out in a systematic manner FDC realized that overtime production over the week- with some assurance that the final schedule assigns ends will be a fact of life until the yields are suffi- production of parts to machines in an optimal man- ciently improved. Due to a long standing policy of not ner. Since production employees are paid time and keeping any finished goods inventory at the end of half for overtime work, Tom is very keen on meeting a week, weekly production is limited to that week's the demand for the five parts with the least amount demand of overtime Setting up machines to produce various parts takes Tom is also curious about the impact of the com- significant amount of machine time, ranging from 8 to pany policy to not carry finished-goods inventory 24 hours as shown in Table 3 and setup times do not from week to week. He has had discussions with the depend on the order in which the parts are produced maintenance supervisor that lead him to believe that on a machine. Setup and production of a part can it should be possible to perform routine maintenance span more than one shift without any lost time. How- during weekends without disturbing the machine ever, as a consequence of preventive maintenance setups

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts