Question: use arena simulation Question 1 14 Points A single machine is designed to produce three parts (A, B, and C). Each part will have its

use arena simulation

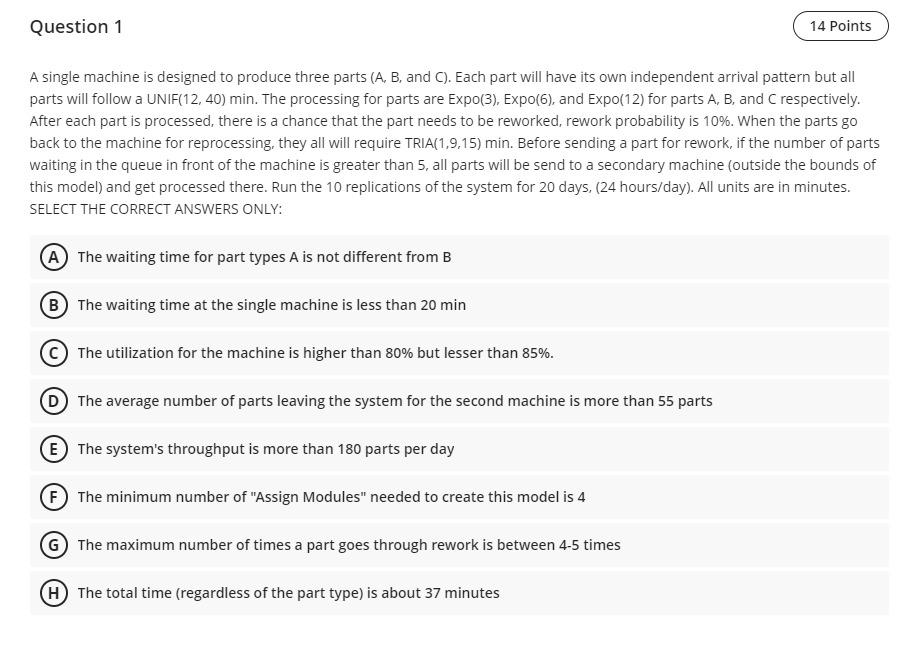

Question 1 14 Points A single machine is designed to produce three parts (A, B, and C). Each part will have its own independent arrival pattern but all parts will follow a UNIF(12, 40) min. The processing for parts are Expo(3), Expo(6), and Expo(12) for parts A, B, and C respectively. After each part is processed, there is a chance that the part needs to be reworked, rework probability is 10%. When the parts go back to the machine for reprocessing, they all will require TRIA(1,9,15) min. Before sending a part for rework, if the number of parts waiting in the queue in front of the machine is greater than 5, all parts will be send to a secondary machine (outside the bounds of this model) and get processed there. Run the 10 replications of the system for 20 days. (24 hours/day). All units are in minutes. SELECT THE CORRECT ANSWERS ONLY: A The waiting time for part types A is not different from B B The waiting time at the single machine is less than 20 min The utilization for the machine is higher than 80% but lesser than 85%. D The average number of parts leaving the system for the second machine is more than 55 parts The system's throughput is more than 180 parts per day The minimum number of "Assign Modules" needed to create this model is 4 G The maximum number of times a part goes through rework is between 4-5 times H The total time (regardless of the part type) is about 37 minutes Question 1 14 Points A single machine is designed to produce three parts (A, B, and C). Each part will have its own independent arrival pattern but all parts will follow a UNIF(12, 40) min. The processing for parts are Expo(3), Expo(6), and Expo(12) for parts A, B, and C respectively. After each part is processed, there is a chance that the part needs to be reworked, rework probability is 10%. When the parts go back to the machine for reprocessing, they all will require TRIA(1,9,15) min. Before sending a part for rework, if the number of parts waiting in the queue in front of the machine is greater than 5, all parts will be send to a secondary machine (outside the bounds of this model) and get processed there. Run the 10 replications of the system for 20 days. (24 hours/day). All units are in minutes. SELECT THE CORRECT ANSWERS ONLY: A The waiting time for part types A is not different from B B The waiting time at the single machine is less than 20 min The utilization for the machine is higher than 80% but lesser than 85%. D The average number of parts leaving the system for the second machine is more than 55 parts The system's throughput is more than 180 parts per day The minimum number of "Assign Modules" needed to create this model is 4 G The maximum number of times a part goes through rework is between 4-5 times H The total time (regardless of the part type) is about 37 minutesStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock