Question: use level strategy utilize full working hours of the current number ofworkers with overtime for fullfiling each month demand make with strategy aggregate planning Month

use level strategy utilize full working hours of the current number ofworkers with overtime for fullfiling each month demand

make with strategy aggregate planning

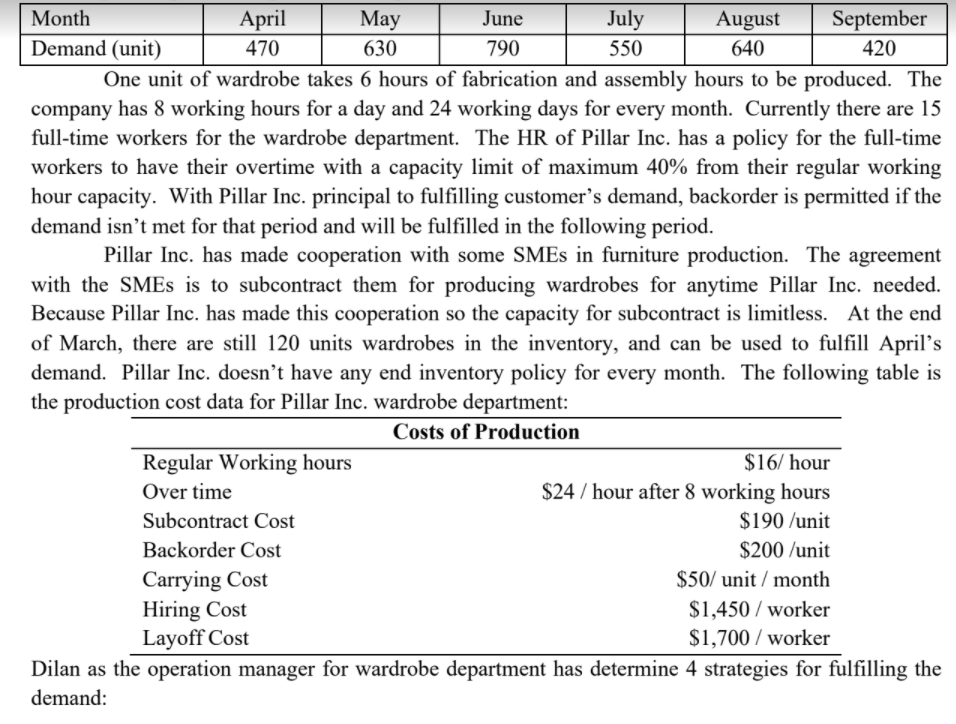

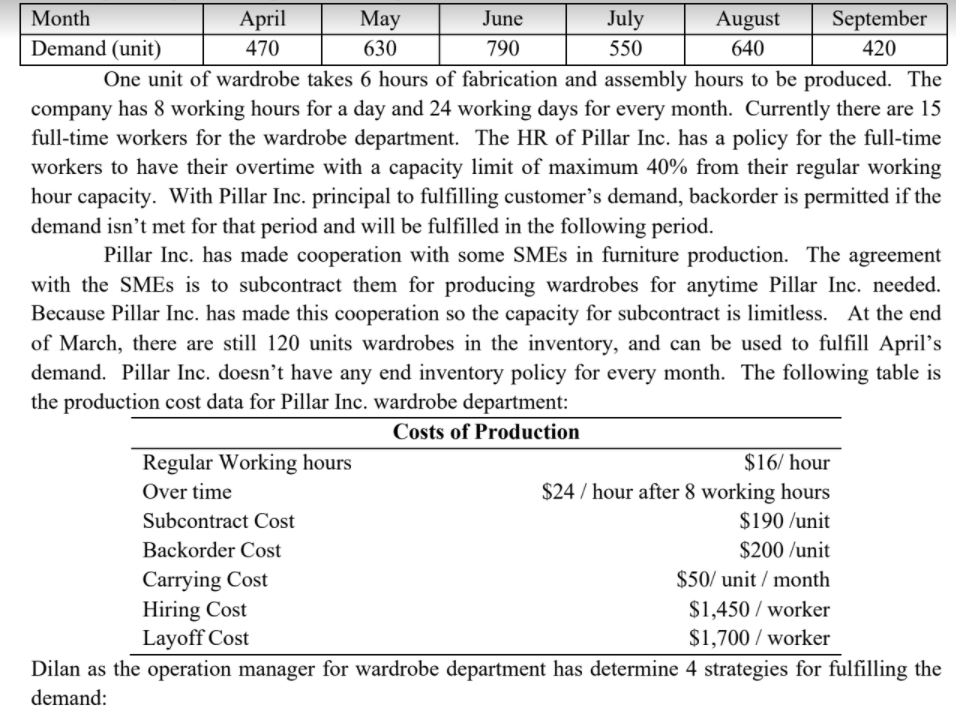

Month April May June July August September Demand (unit) 470 630 790 550 640 420 One unit of wardrobe takes 6 hours of fabrication and assembly hours to be produced. The company has 8 working hours for a day and 24 working days for every month. Currently there are 15 full-time workers for the wardrobe department. The HR of Pillar Inc. has a policy for the full-time workers to have their overtime with a capacity limit of maximum 40% from their regular working hour capacity. With Pillar Inc. principal to fulfilling customer's demand, backorder is permitted if the demand isn't met for that period and will be fulfilled in the following period. Pillar Inc. has made cooperation with some SMEs in furniture production. The agreement with the SMEs is to subcontract them for producing wardrobes for anytime Pillar Inc. needed. Because Pillar Inc. has made this cooperation so the capacity for subcontract is limitless. At the end of March, there are still 120 units wardrobes in the inventory, and can be used to fulfill April's demand. Pillar Inc. doesn't have any end inventory policy for every month. The following table is the production cost data for Pillar Inc. wardrobe department: Costs of Production Regular Working hours $16/ hour Over time $24 / hour after 8 working hours Subcontract Cost $190 /unit Backorder Cost $200/unit Carrying Cost $50/unit/month Hiring Cost $1,450 / worker Layoff Cost $1,700 / worker Dilan as the operation manager for wardrobe department has determine 4 strategies for fulfilling the demand: Month April May June July August September Demand (unit) 470 630 790 550 640 420 One unit of wardrobe takes 6 hours of fabrication and assembly hours to be produced. The company has 8 working hours for a day and 24 working days for every month. Currently there are 15 full-time workers for the wardrobe department. The HR of Pillar Inc. has a policy for the full-time workers to have their overtime with a capacity limit of maximum 40% from their regular working hour capacity. With Pillar Inc. principal to fulfilling customer's demand, backorder is permitted if the demand isn't met for that period and will be fulfilled in the following period. Pillar Inc. has made cooperation with some SMEs in furniture production. The agreement with the SMEs is to subcontract them for producing wardrobes for anytime Pillar Inc. needed. Because Pillar Inc. has made this cooperation so the capacity for subcontract is limitless. At the end of March, there are still 120 units wardrobes in the inventory, and can be used to fulfill April's demand. Pillar Inc. doesn't have any end inventory policy for every month. The following table is the production cost data for Pillar Inc. wardrobe department: Costs of Production Regular Working hours $16/ hour Over time $24 / hour after 8 working hours Subcontract Cost $190 /unit Backorder Cost $200/unit Carrying Cost $50/unit/month Hiring Cost $1,450 / worker Layoff Cost $1,700 / worker Dilan as the operation manager for wardrobe department has determine 4 strategies for fulfilling the demand: Month April May June July August September Demand (unit) 470 630 790 550 640 420 One unit of wardrobe takes 6 hours of fabrication and assembly hours to be produced. The company has 8 working hours for a day and 24 working days for every month. Currently there are 15 full-time workers for the wardrobe department. The HR of Pillar Inc. has a policy for the full-time workers to have their overtime with a capacity limit of maximum 40% from their regular working hour capacity. With Pillar Inc. principal to fulfilling customer's demand, backorder is permitted if the demand isn't met for that period and will be fulfilled in the following period. Pillar Inc. has made cooperation with some SMEs in furniture production. The agreement with the SMEs is to subcontract them for producing wardrobes for anytime Pillar Inc. needed. Because Pillar Inc. has made this cooperation so the capacity for subcontract is limitless. At the end of March, there are still 120 units wardrobes in the inventory, and can be used to fulfill April's demand. Pillar Inc. doesn't have any end inventory policy for every month. The following table is the production cost data for Pillar Inc. wardrobe department: Costs of Production Regular Working hours $16/ hour Over time $24 / hour after 8 working hours Subcontract Cost $190 /unit Backorder Cost $200/unit Carrying Cost $50/unit/month Hiring Cost $1,450 / worker Layoff Cost $1,700 / worker Dilan as the operation manager for wardrobe department has determine 4 strategies for fulfilling the demand: Month April May June July August September Demand (unit) 470 630 790 550 640 420 One unit of wardrobe takes 6 hours of fabrication and assembly hours to be produced. The company has 8 working hours for a day and 24 working days for every month. Currently there are 15 full-time workers for the wardrobe department. The HR of Pillar Inc. has a policy for the full-time workers to have their overtime with a capacity limit of maximum 40% from their regular working hour capacity. With Pillar Inc. principal to fulfilling customer's demand, backorder is permitted if the demand isn't met for that period and will be fulfilled in the following period. Pillar Inc. has made cooperation with some SMEs in furniture production. The agreement with the SMEs is to subcontract them for producing wardrobes for anytime Pillar Inc. needed. Because Pillar Inc. has made this cooperation so the capacity for subcontract is limitless. At the end of March, there are still 120 units wardrobes in the inventory, and can be used to fulfill April's demand. Pillar Inc. doesn't have any end inventory policy for every month. The following table is the production cost data for Pillar Inc. wardrobe department: Costs of Production Regular Working hours $16/ hour Over time $24 / hour after 8 working hours Subcontract Cost $190 /unit Backorder Cost $200/unit Carrying Cost $50/unit/month Hiring Cost $1,450 / worker Layoff Cost $1,700 / worker Dilan as the operation manager for wardrobe department has determine 4 strategies for fulfilling the demand

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts