Question: Useful formulas Bernoulli equation: p + 1 2 u 2 + g z = constant along a streamline p + u 2 R d n

Useful formulas

Bernoulli equation:

constant along a streamline

constant across a streamline.

Continuity equation mass conservation

A duct connects station to the float chamber such that the freesurface pressure inside the chamber

is also The pressure difference between the float chamber and station drives the fuel to inject

into the throat of the venturi with an elevation gain The injection to the throat can be treated

as a free jet with jet speed Determine the jet speed as a function of

and Not all known parameters may appear in your expression. pt

With the fuel jet speed determined, the mass injection rate of the fuel can be readily obtained by

where is the crosssectional area of the jet. Now, neglect the elevation effect in

the expression of ie set and find an expression of the airtofuel ratio

AFR

as a function of given parameters and Not all known parameters may

appear in your expression. pts

Ideally, the airfuel ratio AFR should be held as a constant the stoichiometric ratio regardless of

the running speed of the engine. The running speed of the engine is controlled by the throttle, and

openingclosing the throttle effectively changes the venturi inlet pressure, Potentially usefuProblem : Fluid mechanics in carburetors

A carburetor is a device that mixes air and fuel and supplies the mixture to sparkignition engines. Before

s it was the most commonly used method for fuel delivery in the automotive industry until replaced

by fuel injectors, that were proven to be cleaner and more efficient. While all production vehicles today

use computerized fuel injection systems to feed fuel directly into the combustion chamber of the engine,

some motor fans are still captivated by carburetors for their pure mechanical delicacy, craftsmanship,

and elegant working principles behind them. Such an allure to their mechanical character is similar

to the emotional preference towards automatic watches over quartz ones, or manual transmissions over

automatic transmissions. Let us take this chance to reminisce about the old days by appreciating the

working principles of carburetors.

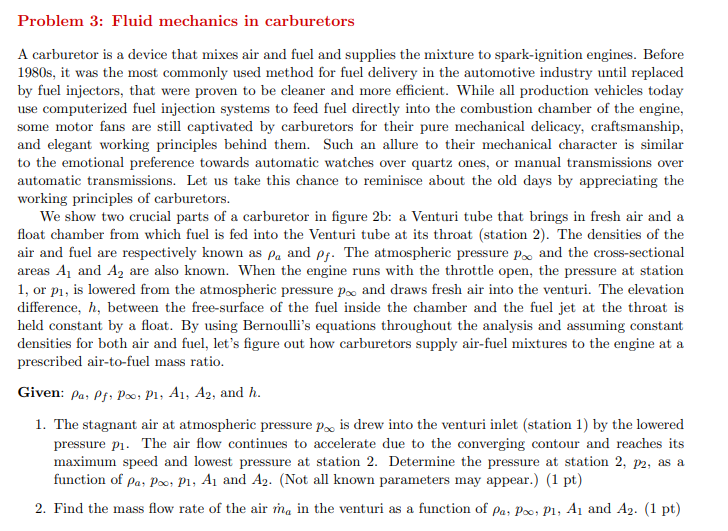

We show two crucial parts of a carburetor in figure b: a Venturi tube that brings in fresh air and a

float chamber from which fuel is fed into the Venturi tube at its throat station The densities of the

air and fuel are respectively known as and The atmospheric pressure and the crosssectional

areas and are also known. When the engine runs with the throttle open, the pressure at station

or is lowered from the atmospheric pressure and draws fresh air into the venturi. The elevation

difference, between the freesurface of the fuel inside the chamber and the fuel jet at the throat is

held constant by a float. By using Bernoulli's equations throughout the analysis and assuming constant

densities for both air and fuel, let's figure out how carburetors supply airfuel mixtures to the engine at a

prescribed airtofuel mass ratio.

Given: and

The stagnant air at atmospheric pressure is drew into the venturi inlet station by the lowered

pressure The air flow continues to accelerate due to the converging contour and reaches its

maximum speed and lowest pressure at station Determine the pressure at station as a

function of and Not all known parameters may appear. pt

Find the mass flow rate of the air in the venturi as a function of and pt

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock