Question: Using incremental analysis, determine if the table cleaner should be processed further. Don't Process Table Cleaner Further Process Table Cleaner Further Net Income Increase (Decrease)

Using incremental analysis, determine if the table cleaner should be processed further.

Using incremental analysis, determine if the table cleaner should be processed further.

| Don't Process Table Cleaner Further | Process Table Cleaner Further | Net Income Increase (Decrease) | |

| Incremental Revenue | 337122 | 549384 | 212262 |

| Incremental Cost | ? | ? | ? |

| Total | ? | ? | ? |

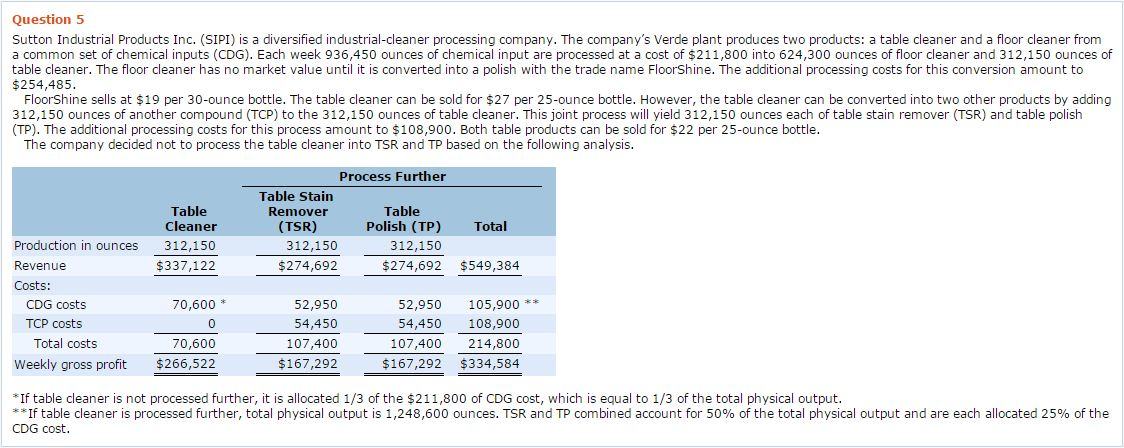

Question 5 Sutton Industrial Products Inc. (SIPI) is a diversified industrial-cleaner processing company. The company's Verde plant produces two products: a table cleaner and a floor cleaner from a common set of chemical inputs (CDG). Each week 936,450 ounces of chemical input are processed at a cost of $211,800 into 624,300 ounces of floor cleaner and 312,150 ounces of table cleaner. The floor cleaner has no market value until it is converted into a polish with the trade name FloorShine. The additional processing costs for this conversion amount to $254,485 FloorShine sells at $19 per 30-ounce bottle. The table cleaner can be sold for $27 per 25-ounce bottle. However, the table cleaner can be converted into two other products by adding 312,150 ounces of another compound (TCP) to the 312,150 ounces of table cleaner. This joint process will yield 312,150 ounces each of table stain remover (TSR) and table polish (TP). The additional processing costs for this process amount to $108,900. Both table products can be sold for $22 per 25-ounce bottle The company decided not to process the table cleaner into TSR and TP based on the following analysis. Process Further Table Stain Table Cleaner 312,150 $337,12:2 Remover (TSR) Table Polish (TP) Total Production in ounces Revenue Costs: 312,150 $274,692 312,150 $274,692 $549,384 52,950 54,450 107,400 $167,29:2 70,600* 52,950 105,900 ** CDG costs TCP costs 0 70,600 $266,522 54,450 108,900 107,400 214,800 $167,292 $334,584 Total costs Weekly gross profit If table cleaner is not processed further, it is allocated 1/3 of the $211,800 of CDG cost, which is equal to 1/3 of the total physical output. *"If table cleaner is processed further, total physical output is 1,248,600 ounces. TSR and TP combined account for 50% of the total physical output and are each allocated 25% of the CDG cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts