Question: Using Pareto analysis, categorize the products into classes A,B,C based on usage value. Would this approach be useful for categorizing and controlling stock levels of

Using Pareto analysis, categorize the products into classes A,B,C based on usage value. Would this approach be useful for categorizing and controlling stock levels of all the products at TEP?

Using Pareto analysis, categorize the products into classes A,B,C based on usage value. Would this approach be useful for categorizing and controlling stock levels of all the products at TEP?

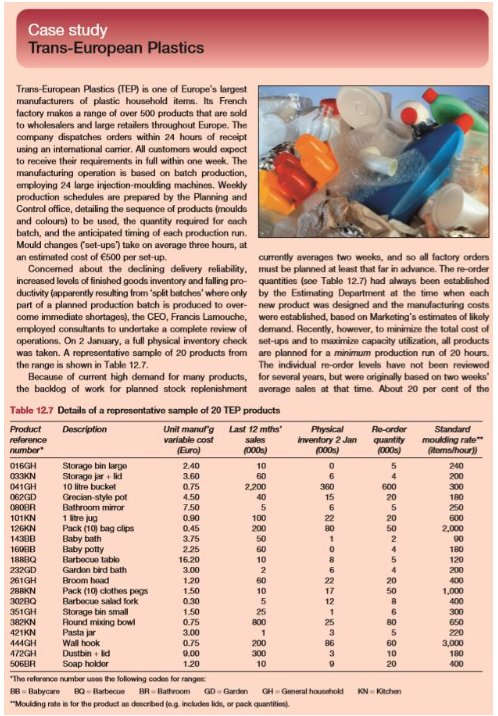

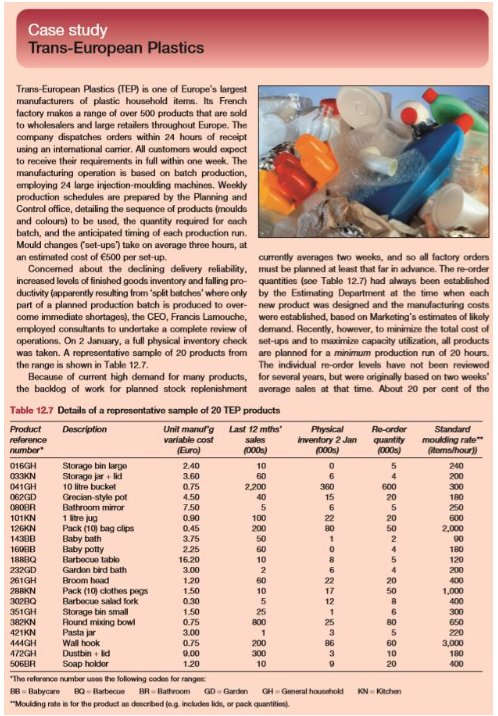

Case study Trans-European Plastics Trans-European Plastics (TEP) is one of Europe's largest manufacturers of plastic household items. Its French factory makes a range of over 500 products that are sold to wholesalers and large retailers throughout Europe. The company dispatches orders within 24 hours of receipt using an international carrier. All customers would expect to receive their requirements in full within one week. The manufacturing operation is based on batch production, employing 24 large injection-moulding machines. Weekly production schedules are prepared by the Planning and Control office, detailing the sequence of products (moulds and colours) to be used, the quantity required for each batch, and the anticipated timing of each production run. Mould changes (set-ups) take on average three hours, at an estimated cost of 500 per set-up. currently averages two weeks, and so all factory orders Concerned about the declining delivery reliability. must be planned at least that far in advance. The re-order increased levels of finished goods inventory and falling pro quantities (see Table 12.7) had always been established ductivity (apparently resulting from split batches where only by the Estimating Department at the time when each part of a planned production batch is produced to over new product was designed and the manufacturing costs come immediate shortages), the CEO, Francis Lamouche, were established, based on Marketing's estimates of likely employed consultants to undertake a complete review of demand. Recently, however, to minimize the total cost of operations. On 2 January, a full physical inventory check set-ups and to maximize capacity utilization, all products was taken. A representative sample of 20 products from are planned for a minimum production run of 20 hours. the range is shown in Table 12.7. The individual re-order levels have not been reviewed Because of current high demand for many products, for several years, but were originally based on two weeks' the backlog of work for planned stock replenishment average sales at that time. About 20 per cent of the Table 127 Details of a representative sample of 20 TEP products Product Description Unit manufg Last 12 mths' Physical Re-order Standard reference variable cost sales inventory 2 Jan quantity moulding rate" number (Euro) (000) 000) (OOO) items/hour)) 016GH Storage bin largo 2.40 10 0 5 240 033KN Storage jarlid 3.60 60 6 200 041GH 10 litre bucket 0.75 2.200 360 600 300 062GD Grecian-style pot 4.50 40 15 20 180 0B0BR Bathroom mirror 7.50 6 5 250 101KN 1 Itre jug 0.90 100 22 20 600 126KN Pack (10) bag clips 0.45 200 80 50 2,000 143BB Baby bath 3.75 50 1 2 90 160BB Baby potty 2.25 60 0 4 180 18880 Barbecue tablo 16.20 8 5 120 232GD Gardon bird bath 3.00 2. 6 200 261GH Broom head 1.20 60 22 20 400 280KN Pack (10) clothes pegs 1.50 10 17 50 1,000 30280 Barbecue salad fork 0.30 12 400 351GH Storage bin small 1.50 25 1 6 300 382KN Round mixing bowl 0.75 800 25 80 650 421KN Pastaja 3.00 1 3 5 220 444GH Wall hook 0.75 86 60 3,000 472GH Dustbin lid 9.00 300 3 180 506BR Soap holder 1.20 10 20 400 'The reference number use the following codes for ranges BBBabycare BO - Barbecue BR-Bathroom GD Garden GH-General household KN Kitchen Moulding rate is for the product as described leg. includes lide, or pack quantities 5 10 5 10 products are very seasonal (e.g. Garden Range), with peak replace contract warehousing and associated transport demand from April to August. Storage bins sell particularly which is costing us about 5 per cent of the manufacturing well from October to December. costs of the stored items. The return on investment for this The European Marketing Manager summarized the project is well above our current 8 per cent cost of capital. current position, 'Our coverage of the market has never There is no viable alternative, because if we run out of been so comprehensive; we are able to offer a full range of space, production will have to stop for a time. Some of our household plastics, which appeals to most European tastes. products occupy very large volumes of rack space. How- But we will not retain our newly developed markets unless ever, in the meantime we have decided to review all the we can give distributors confidence that we will supply all re-order quantities. They seem either to result in excessive their orders within one week. Unfortunately, at the moment, stock or too little stock to provide the service required. many receive several deliveries for each order, spread over Large items such as the Baby Bath (tem 143BB) could many weeks. This certainly increases their administrative be looked at first. This is a good starting point because and handling costs, and our haulage costs. And sometimes the product has stable and non-seasonal demand. We the shortfall is only some small, low-value items like clothes estimate that it costs us around 20 per cent of the manu- pegs.' facturing variable costs to store such items for one year.' The factory operates on three seven-hour shifts, Monday to Friday: 105 hours per week, for 50 weeks per year. Regular Questions overtime, typically 15 hours on a Saturday, has been worked most of the last year. Sunday is never used for production, 1 Why is TEP unable to deliver all its products reliably allowing access to machines for routine and major overhauls. within the target of one week, and what effects might that have on the distributors? Machines are laid out in groups so that each operator can be kept highly utilized, attending to at least four machines. 2 What internal problems result from the current planning Any product can be made on any machine. and control policies? In particular, analyse stock turns Pierre Dumas, the production manager, was concerned and availability (e.g. high and low levels). about storage space: 'At the moment our warehouse is tull, with products stacked on the floor in every available 3 Using Pareto analysis, categorize the products into comer, which makes it vulnerable to damage from passing Classes A,B,C, based on usage value. Would this forklifts and from double-handling. We have finally agreed approach be useful for categorizing and controlling to approve an extension (costing over one million Euros) stock levels of all the products at TEP? to be constructed in June-September this year, which will 4 What overall recommendations would you make to Francis Lamouche about the proposed investment in the warehouse extension? Case study Trans-European Plastics Trans-European Plastics (TEP) is one of Europe's largest manufacturers of plastic household items. Its French factory makes a range of over 500 products that are sold to wholesalers and large retailers throughout Europe. The company dispatches orders within 24 hours of receipt using an international carrier. All customers would expect to receive their requirements in full within one week. The manufacturing operation is based on batch production, employing 24 large injection-moulding machines. Weekly production schedules are prepared by the Planning and Control office, detailing the sequence of products (moulds and colours) to be used, the quantity required for each batch, and the anticipated timing of each production run. Mould changes (set-ups) take on average three hours, at an estimated cost of 500 per set-up. currently averages two weeks, and so all factory orders Concerned about the declining delivery reliability. must be planned at least that far in advance. The re-order increased levels of finished goods inventory and falling pro quantities (see Table 12.7) had always been established ductivity (apparently resulting from split batches where only by the Estimating Department at the time when each part of a planned production batch is produced to over new product was designed and the manufacturing costs come immediate shortages), the CEO, Francis Lamouche, were established, based on Marketing's estimates of likely employed consultants to undertake a complete review of demand. Recently, however, to minimize the total cost of operations. On 2 January, a full physical inventory check set-ups and to maximize capacity utilization, all products was taken. A representative sample of 20 products from are planned for a minimum production run of 20 hours. the range is shown in Table 12.7. The individual re-order levels have not been reviewed Because of current high demand for many products, for several years, but were originally based on two weeks' the backlog of work for planned stock replenishment average sales at that time. About 20 per cent of the Table 127 Details of a representative sample of 20 TEP products Product Description Unit manufg Last 12 mths' Physical Re-order Standard reference variable cost sales inventory 2 Jan quantity moulding rate" number (Euro) (000) 000) (OOO) items/hour)) 016GH Storage bin largo 2.40 10 0 5 240 033KN Storage jarlid 3.60 60 6 200 041GH 10 litre bucket 0.75 2.200 360 600 300 062GD Grecian-style pot 4.50 40 15 20 180 0B0BR Bathroom mirror 7.50 6 5 250 101KN 1 Itre jug 0.90 100 22 20 600 126KN Pack (10) bag clips 0.45 200 80 50 2,000 143BB Baby bath 3.75 50 1 2 90 160BB Baby potty 2.25 60 0 4 180 18880 Barbecue tablo 16.20 8 5 120 232GD Gardon bird bath 3.00 2. 6 200 261GH Broom head 1.20 60 22 20 400 280KN Pack (10) clothes pegs 1.50 10 17 50 1,000 30280 Barbecue salad fork 0.30 12 400 351GH Storage bin small 1.50 25 1 6 300 382KN Round mixing bowl 0.75 800 25 80 650 421KN Pastaja 3.00 1 3 5 220 444GH Wall hook 0.75 86 60 3,000 472GH Dustbin lid 9.00 300 3 180 506BR Soap holder 1.20 10 20 400 'The reference number use the following codes for ranges BBBabycare BO - Barbecue BR-Bathroom GD Garden GH-General household KN Kitchen Moulding rate is for the product as described leg. includes lide, or pack quantities 5 10 5 10 products are very seasonal (e.g. Garden Range), with peak replace contract warehousing and associated transport demand from April to August. Storage bins sell particularly which is costing us about 5 per cent of the manufacturing well from October to December. costs of the stored items. The return on investment for this The European Marketing Manager summarized the project is well above our current 8 per cent cost of capital. current position, 'Our coverage of the market has never There is no viable alternative, because if we run out of been so comprehensive; we are able to offer a full range of space, production will have to stop for a time. Some of our household plastics, which appeals to most European tastes. products occupy very large volumes of rack space. How- But we will not retain our newly developed markets unless ever, in the meantime we have decided to review all the we can give distributors confidence that we will supply all re-order quantities. They seem either to result in excessive their orders within one week. Unfortunately, at the moment, stock or too little stock to provide the service required. many receive several deliveries for each order, spread over Large items such as the Baby Bath (tem 143BB) could many weeks. This certainly increases their administrative be looked at first. This is a good starting point because and handling costs, and our haulage costs. And sometimes the product has stable and non-seasonal demand. We the shortfall is only some small, low-value items like clothes estimate that it costs us around 20 per cent of the manu- pegs.' facturing variable costs to store such items for one year.' The factory operates on three seven-hour shifts, Monday to Friday: 105 hours per week, for 50 weeks per year. Regular Questions overtime, typically 15 hours on a Saturday, has been worked most of the last year. Sunday is never used for production, 1 Why is TEP unable to deliver all its products reliably allowing access to machines for routine and major overhauls. within the target of one week, and what effects might that have on the distributors? Machines are laid out in groups so that each operator can be kept highly utilized, attending to at least four machines. 2 What internal problems result from the current planning Any product can be made on any machine. and control policies? In particular, analyse stock turns Pierre Dumas, the production manager, was concerned and availability (e.g. high and low levels). about storage space: 'At the moment our warehouse is tull, with products stacked on the floor in every available 3 Using Pareto analysis, categorize the products into comer, which makes it vulnerable to damage from passing Classes A,B,C, based on usage value. Would this forklifts and from double-handling. We have finally agreed approach be useful for categorizing and controlling to approve an extension (costing over one million Euros) stock levels of all the products at TEP? to be constructed in June-September this year, which will 4 What overall recommendations would you make to Francis Lamouche about the proposed investment in the warehouse extension

Using Pareto analysis, categorize the products into classes A,B,C based on usage value. Would this approach be useful for categorizing and controlling stock levels of all the products at TEP?

Using Pareto analysis, categorize the products into classes A,B,C based on usage value. Would this approach be useful for categorizing and controlling stock levels of all the products at TEP?