Question: Using the data from the value stream mapping below and the table, calculate the current state performance of the cell and answer the following questions?

Using the data from the value stream mapping below and the table, calculate the current state performance of the cell and answer the following questions?

What is the capacity of this manufacturing cell?

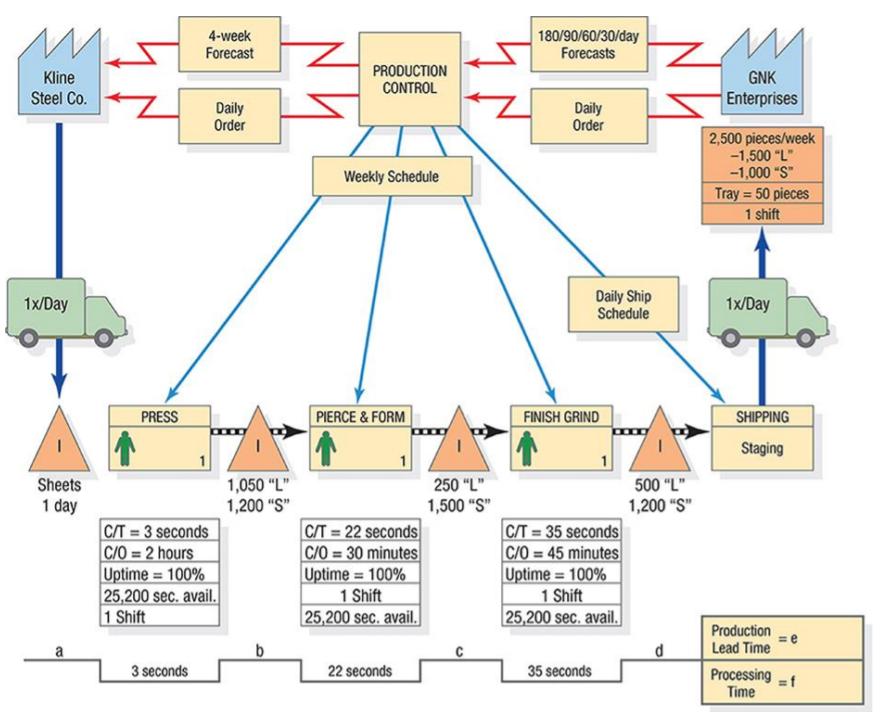

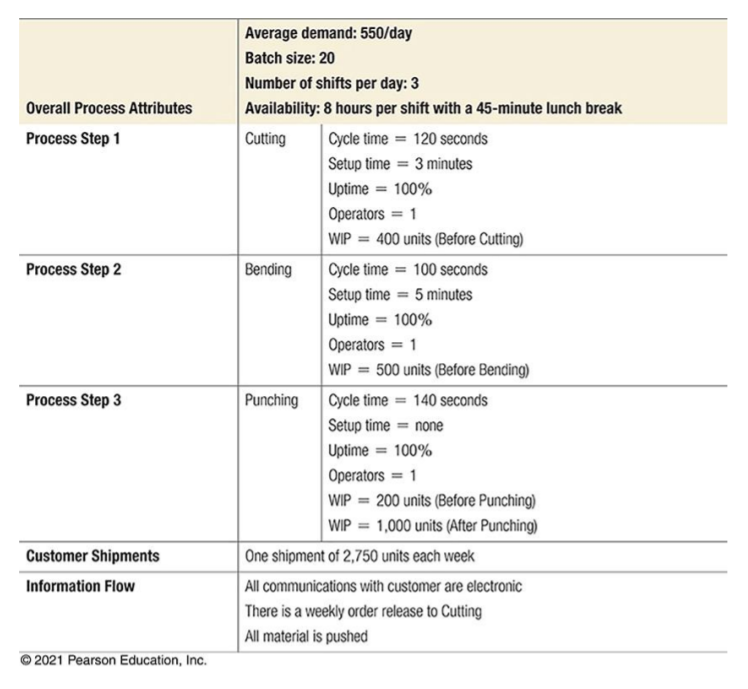

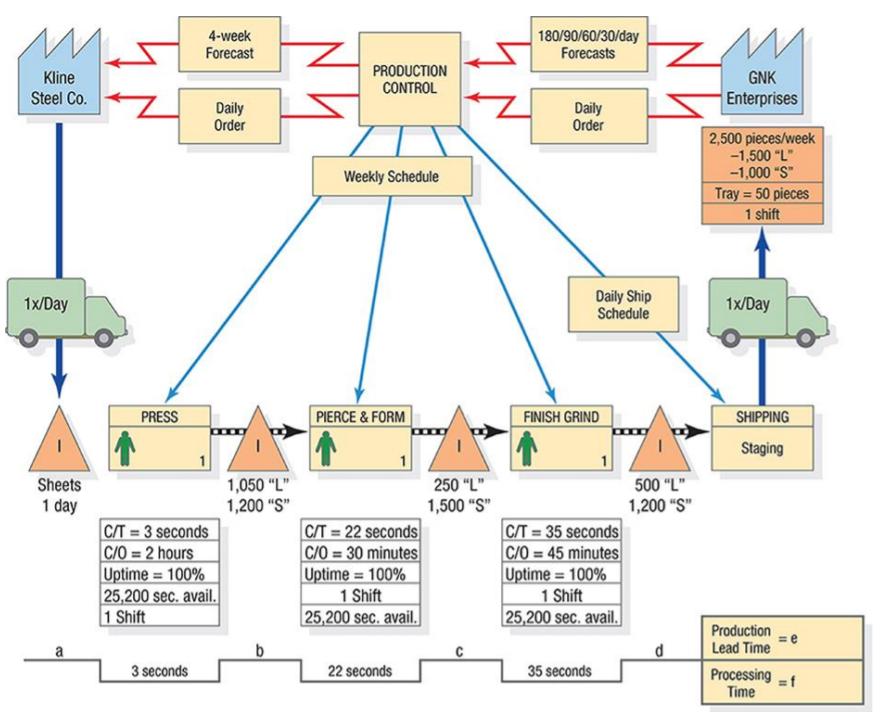

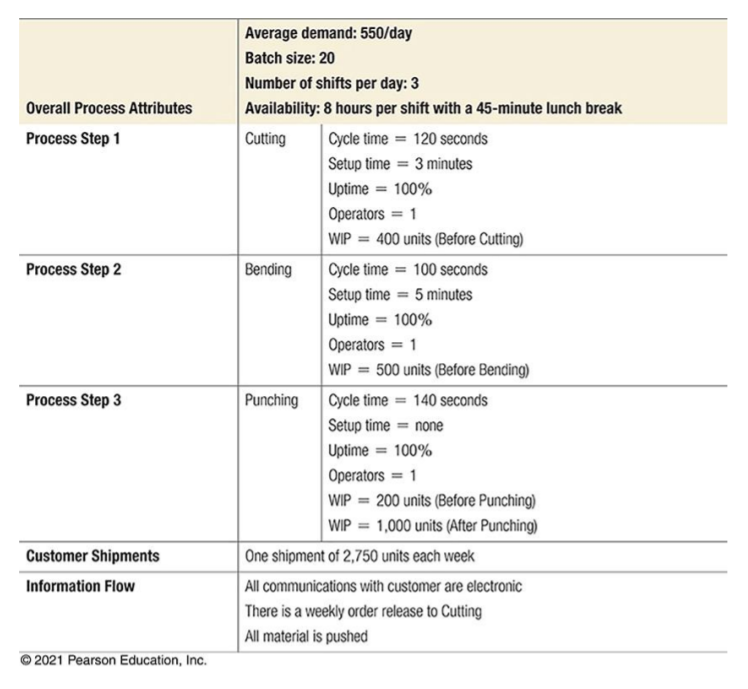

4-week Forecast 180/90/60/30/day Forecasts Kline Steel Co. PRODUCTION CONTROL GNK Enterprises Daily Order Daily Order Weekly Schedule 2,500 pieces/week -1,500 "L" -1,000 "S" Tray = 50 pieces 1 shift 1x/Day Daily Ship Schedule 1x/Day PRESS PIERCE & FORM FINISH GRIND A SHIPPING Staging Sheets 1 day 1,050 "L" 1,200 "S" C/T = 3 seconds C/O = 2 hours Uptime = 100% 25,200 sec. avail. 1 Shift 1 250 "L" 1,500 "S" C/T = 22 seconds C/O = 30 minutes Uptime = 100% 1 Shift 25,200 sec. avail. 500 "L" 1,200 "S" C/T = 35 seconds C/O = 45 minutes Uptime = 100% 1 Shift 25,200 sec. avail. a b d Production Lead Time Processing Time 3 seconds 22 seconds 35 seconds =f Overall Process Attributes Process Step 1 Process Step 2 Average demand: 550/day Batch size: 20 Number of shifts per day: 3 Availability: 8 hours per shift with a 45-minute lunch break Cutting Cycle time = 120 seconds Setup time = 3 minutes Uptime = 100% Operators = 1 WIP = 400 units (Before Cutting) Bending Cycle time = 100 seconds Setup time = 5 minutes Uptime = 100% Operators = 1 WIP = 500 units (Before Bending) Punching Cycle time = 140 seconds Setup time = none Uptime = 100% Operators = 1 WIP = 200 units (Before Punching) WIP = 1,000 units (After Punching) One shipment of 2,750 units each week All communications with customer are electronic There is a weekly order release to Cutting All material is pushed Process Step 3 Customer Shipments Information Flow 2021 Pearson Education, Inc. 4-week Forecast 180/90/60/30/day Forecasts Kline Steel Co. PRODUCTION CONTROL GNK Enterprises Daily Order Daily Order Weekly Schedule 2,500 pieces/week -1,500 "L" -1,000 "S" Tray = 50 pieces 1 shift 1x/Day Daily Ship Schedule 1x/Day PRESS PIERCE & FORM FINISH GRIND A SHIPPING Staging Sheets 1 day 1,050 "L" 1,200 "S" C/T = 3 seconds C/O = 2 hours Uptime = 100% 25,200 sec. avail. 1 Shift 1 250 "L" 1,500 "S" C/T = 22 seconds C/O = 30 minutes Uptime = 100% 1 Shift 25,200 sec. avail. 500 "L" 1,200 "S" C/T = 35 seconds C/O = 45 minutes Uptime = 100% 1 Shift 25,200 sec. avail. a b d Production Lead Time Processing Time 3 seconds 22 seconds 35 seconds =f Overall Process Attributes Process Step 1 Process Step 2 Average demand: 550/day Batch size: 20 Number of shifts per day: 3 Availability: 8 hours per shift with a 45-minute lunch break Cutting Cycle time = 120 seconds Setup time = 3 minutes Uptime = 100% Operators = 1 WIP = 400 units (Before Cutting) Bending Cycle time = 100 seconds Setup time = 5 minutes Uptime = 100% Operators = 1 WIP = 500 units (Before Bending) Punching Cycle time = 140 seconds Setup time = none Uptime = 100% Operators = 1 WIP = 200 units (Before Punching) WIP = 1,000 units (After Punching) One shipment of 2,750 units each week All communications with customer are electronic There is a weekly order release to Cutting All material is pushed Process Step 3 Customer Shipments Information Flow 2021 Pearson Education, Inc