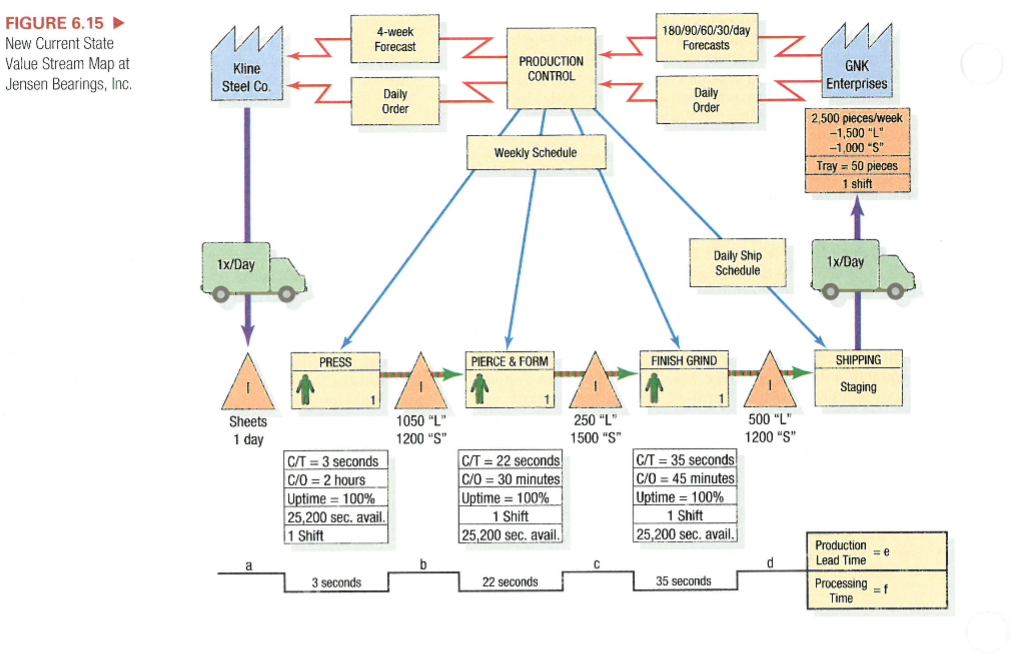

Question: Lean Systems Value Stream Mapping 12. Figure 6.15 provides a new current state value stream map for the family of retainers at the Jensen Bearings,

Lean Systems Value Stream Mapping

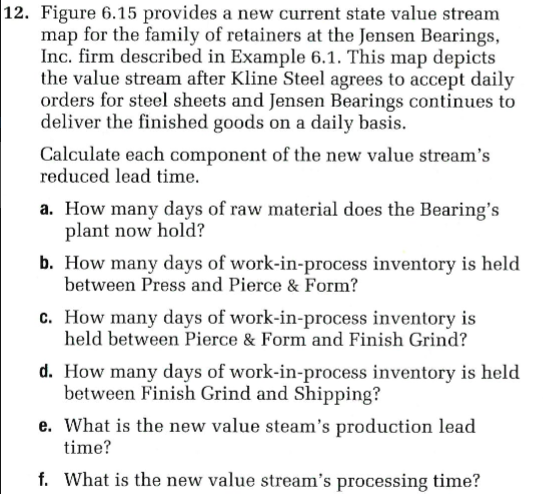

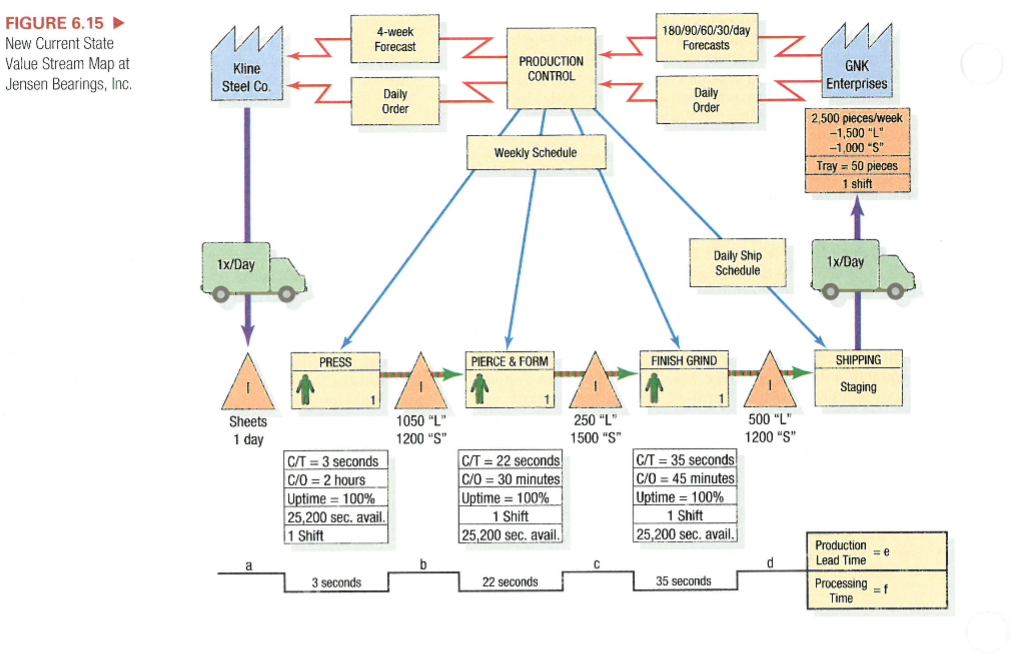

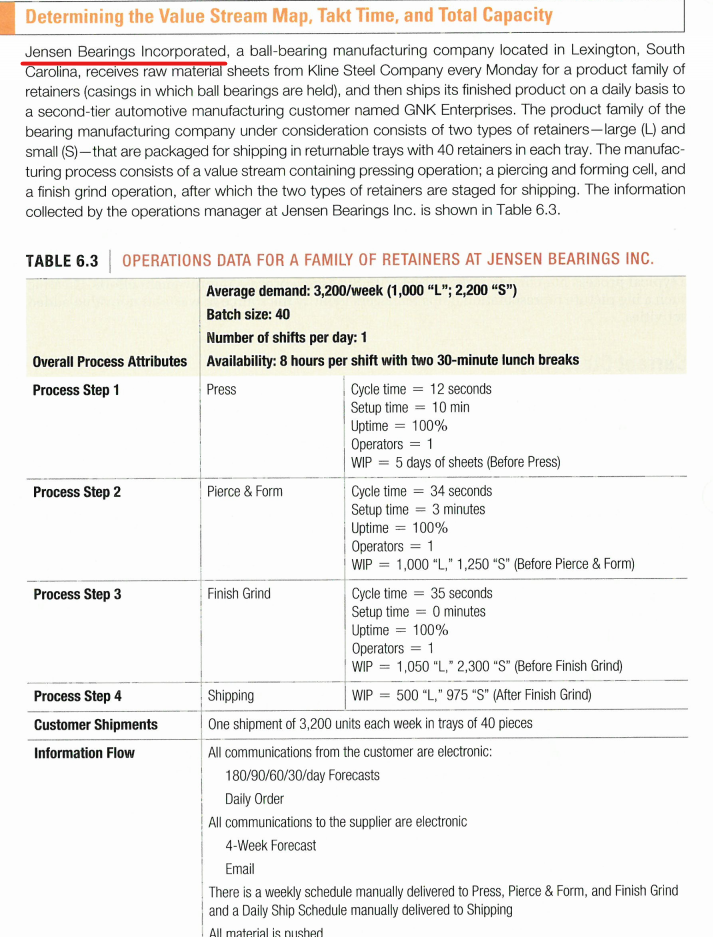

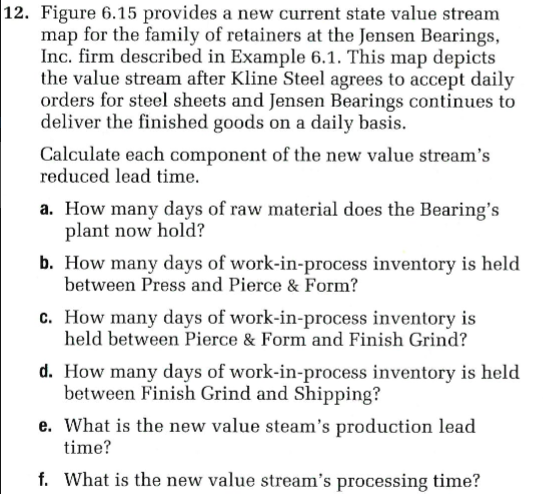

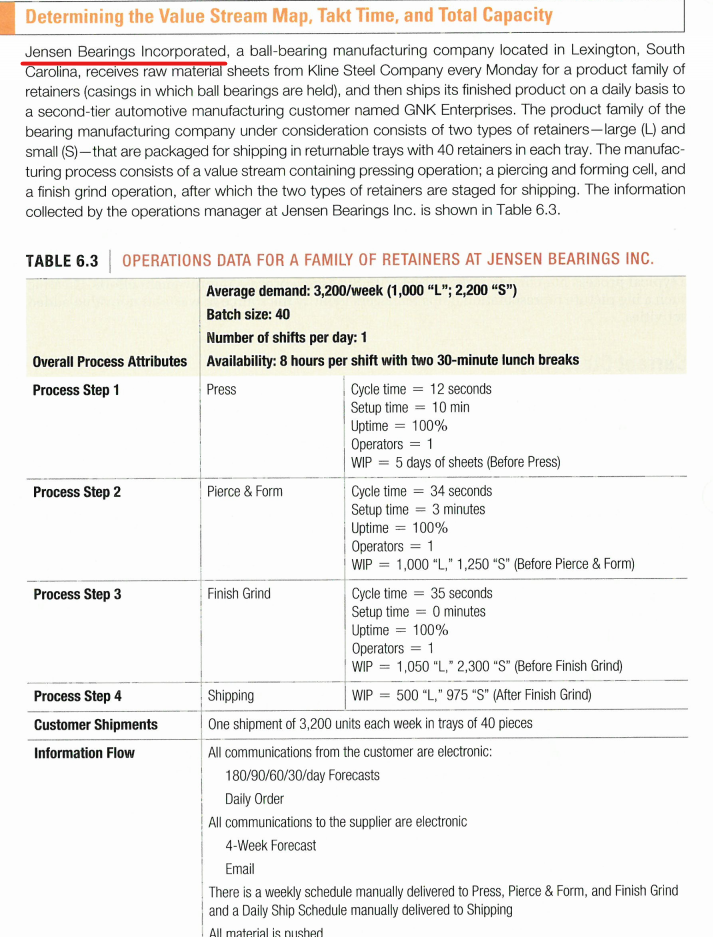

12. Figure 6.15 provides a new current state value stream map for the family of retainers at the Jensen Bearings, Inc. firm described in Example 6.1. This map depicts the value stream after Kline Steel agrees to accept daily orders for steel sheets and Jensen Bearings continues to deliver the finished goods on a daily basis. Calculate each component of the new value stream's reduced lead time. a. How many days of raw material does the Bearing's plant now hold? b. How many days of work-in-process inventory is held between Press and Pierce & Form? C. How many days of work-in-process inventory is held between Pierce & Form and Finish Grind? d. How many days of work-in-process inventory is held between Finish Grind and Shipping? e. What is the new value steam's production lead time? f. What is the new value stream's processing time? 4-week Forecast 180/90/60/30/day Forecasts FIGURE 6.15 New Current State Value Stream Map at Jensen Bearings, Inc. Kline Steel Co PRODUCTION CONTROL GNK Enterprises Daily Order Daily Order Weekly Schedule 2,500 pieces/week -1,500 "L" -1,000 "S" Tray = 50 pieces 1 shift 1x/Day Daily Ship Schedule 1x/Day PRESS PIERCE & FORM FINISH GRIND SHIPPING Staging 1 Sheets 1 day 1050 "L" 1200 "S" 250 "L' 1500 "S" 500 ML 1200 "S" C/T = 3 seconds C/0 = 2 hours Uptime = 100% 25,200 sec. avail 1 Shift C/T = 22 seconds C/O = 30 minutes Uptime = 100% 1 Shift 25,200 sec. avail. C/T = 35 seconds C/O = 45 minutes Uptime = 100% 1 Shift 25,200 sec. avail. =e d Production Lead Time Processing Time 3 seconds 22 seconds 35 seconds =f Determining the Value Stream Map, Takt Time, and Total Capacity Jensen Bearings Incorporated, a ball bearing manufacturing company located in Lexington, South Carolina, receives raw material sheets from Kline Steel Company every Monday for a product family of retainers (casings in which ball bearings are held), and then ships its finished product on a daily basis to a second-tier automotive manufacturing customer named GNK Enterprises. The product family of the bearing manufacturing company under consideration consists of two types of retainers-large (L) and small (S)that are packaged for shipping in returnable trays with 40 retainers in each tray. The manufac- turing process consists of a value stream containing pressing operation; a piercing and forming cell, and a finish grind operation, after which the two types of retainers are staged for shipping. The information collected by the operations manager at Jensen Bearings Inc. is shown in Table 6.3. TABLE 6.3 OPERATIONS DATA FOR A FAMILY OF RETAINERS AT JENSEN BEARINGS INC. Average demand: 3,200/week (1,000 "L"; 2,200 S") Batch size: 40 Number of shifts per day: 1 Overall Process Attributes Availability: 8 hours per shift with two 30-minute lunch breaks Process Step 1 Press Cycle time = 12 seconds Setup time = 10 min Uptime = 100% Operators = 1 WIP = 5 days of sheets (Before Press) Process Step 2 Pierce & Form Cycle time = 34 seconds Setup time = 3 minutes Uptime = 100% Operators = 1 WIP = 1,000 "L," 1,250 "S" (Before Pierce & Form) Process Step 3 Finish Grind Cycle time = 35 seconds Setup time = 0 minutes Uptime = 100% Operators = 1 WIP = 1,050 "L,"2,300 "S" (Before Finish Grind) Process Step 4 Shipping WIP = 500 "L," 975 "S" (After Finish Grind) Customer Shipments One shipment of 3,200 units each week in trays of 40 pieces Information Flow All communications from the customer are electronic: 180/90/60/30/day Forecasts Daily Order All communications to the supplier are electronic 4-Week Forecast Email There is a weekly schedule manually delivered to Press, Pierce & Form, and Finish Grind and a Daily Ship Schedule manually delivered to Shipping All material is pushed