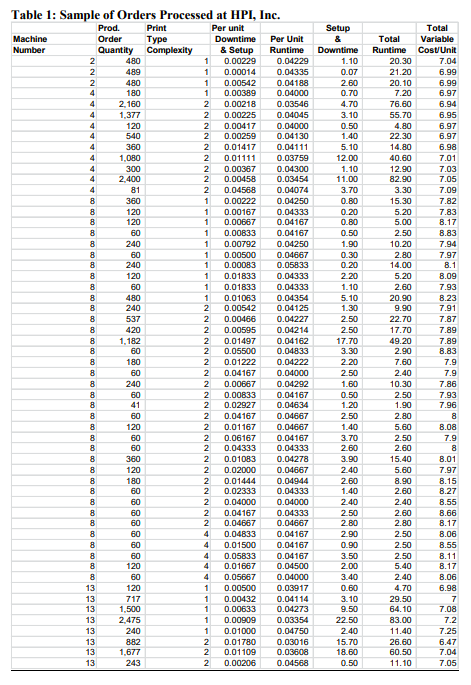

Question: Using the data in Table 1, explain how you would use appropriate methods of analysis such as regression analysis or correlation analysis to analyze the

Using the data in Table 1, explain how you would use appropriate methods of analysis such as regression analysis or correlation analysis to analyze the effect of order size and product variety on the productivity and cost structure of the Lexington plant.

Table 1: Sample of Orders Processed at HPI, Inc. Setup Prod. Print Per unit Total Downtime & Setup Per Unit Machine Order Complexity Total Variable Downtime Runtime Quantity Runtime Cost/Unit Number 1.10 2 480 0.00229 0.04229 20.30 7,04 489 0.00014 0.04335 0.07 21.20 6.99 2 480 1 0.00542 0.04188 2.60 20.10 6.99 4 180 0.00389 0.04000 0.70 7.20 6.97 4 2,160 0.00218 0.03546 4.70 76.60 6,94 4 1.377 0.00225 0.04045 3.10 55.70 6.95 4 120 2 0.00417 0.04000 0.50 4.80 6,97 4 540 0.00259 0.04130 1.40 22.30 6.97 4 360 0.01417 0.04111 5.10 14.80 6.98 0.03759 1.080 0.01111 12.00 40.60 7.01 0.04300 300 0.00367 1.10 12.90 7.03 4 2,400 0.00458 0.03454 11.00 82.90 7.05 4. 0.04074 81 0.04568 3.70 3.30 7.09 0.04250 8 360 1 0.00222 0.80 15.30 7.82 120 1 0.00167 0.04333 020 5.20 7.83 120 0.00667 0.04167 0.80 5.00 8.17 60 1 0.00833 0.04167 0.50 2.50 8.83 240 0.00792 0.04250 1.90 10.20 7,94 8 0.04667 0.05833 60 1 0.00500 0.30 2.80 7.97 8.1 240 1 0.00083 0.20 14.00 0.04333 120 0.01833 2.20 5.20 8.09 0.04333 60 1 0.01833 1.10 2.60 7,93 480 8.23 1 0.01063 0.04354 5.10 20.90 0.04125 240 0.00542 1.30 9.90 7.91 2 537 0.00466 0.04227 250 22.70 7.87 7.89 420 0.00595 0.04214 2.50 17.70 0.04162 17.70 7.89 1,182 0.01497 49.20 60 0.05500 0.04833 3.30 2.90 8.83 180 0.01222 0.04222 0.04000 2.20 7,60 7,9 0.04167 7.9 60 2.50 2,40 0.04292 7.86 240 0.00667 1.60 10.30 0.50 1.20 7.93 60 0.00833 0.04167 2.50 41 0.02927 0.04634 1.90 7.96 0.04667 8 60 0.04167 2.50 2.80 120 0.01167 0.04667 1.40 5,60 8.08 60 0.06167 0.04167 3.70 2.50 7.9 60 0.04333 0.04333 0.04278 260 2.60 8.01 360 0.01083 3.90 15.40 0.04667 120 0.02000 2.40 5.60 7.97 0.01444 8.15 180 0.04944 2.60 8.90 1.40 60 0.02333 0.04333 2.60 8.27 0.04000 60 0.04000 2.40 2,40 8.55 60 0.04167 0.04333 2.50 2.60 8.66 60 2 0.04667 0.04667 2.80 2.80 8.17 4 0.04167 60 0.04833 2.90 2.50 8.06 4 60 0.01500 0.04167 0.90 2.50 8.55 4 0.04167 0.04500 60 0.05833 3.50 2.50 8.11 120 4 0.01667 0.05667 0.00500 2.00 5.40 8.17 4 0.04000 60 3.40 2,40 8.06 120 13 1 0.03917 0.60 4.70 6.98 0.00432 13 717 1 0.04114 3.10 29.50 7.08 13 1,500 1 0.00633 0.04273 9.50 64.10 2,475 83.00 7.2 13 1 0.00909 0.03354 22.50 0.01000 7.25 13 240 1 0.04750 2.40 11.40 6.47 13 882 0.01780 0.03016 0.03608 15.70 26.60 13 1.677 0.01109 18.60 60.50 7.04 13 243 2 0.00206 0.04568. 0.50 11.10 7.05 NNNNNNT Table 1: Sample of Orders Processed at HPI, Inc. Setup Prod. Print Per unit Total Downtime & Setup Per Unit Machine Order Complexity Total Variable Downtime Runtime Quantity Runtime Cost/Unit Number 1.10 2 480 0.00229 0.04229 20.30 7,04 489 0.00014 0.04335 0.07 21.20 6.99 2 480 1 0.00542 0.04188 2.60 20.10 6.99 4 180 0.00389 0.04000 0.70 7.20 6.97 4 2,160 0.00218 0.03546 4.70 76.60 6,94 4 1.377 0.00225 0.04045 3.10 55.70 6.95 4 120 2 0.00417 0.04000 0.50 4.80 6,97 4 540 0.00259 0.04130 1.40 22.30 6.97 4 360 0.01417 0.04111 5.10 14.80 6.98 0.03759 1.080 0.01111 12.00 40.60 7.01 0.04300 300 0.00367 1.10 12.90 7.03 4 2,400 0.00458 0.03454 11.00 82.90 7.05 4. 0.04074 81 0.04568 3.70 3.30 7.09 0.04250 8 360 1 0.00222 0.80 15.30 7.82 120 1 0.00167 0.04333 020 5.20 7.83 120 0.00667 0.04167 0.80 5.00 8.17 60 1 0.00833 0.04167 0.50 2.50 8.83 240 0.00792 0.04250 1.90 10.20 7,94 8 0.04667 0.05833 60 1 0.00500 0.30 2.80 7.97 8.1 240 1 0.00083 0.20 14.00 0.04333 120 0.01833 2.20 5.20 8.09 0.04333 60 1 0.01833 1.10 2.60 7,93 480 8.23 1 0.01063 0.04354 5.10 20.90 0.04125 240 0.00542 1.30 9.90 7.91 2 537 0.00466 0.04227 250 22.70 7.87 7.89 420 0.00595 0.04214 2.50 17.70 0.04162 17.70 7.89 1,182 0.01497 49.20 60 0.05500 0.04833 3.30 2.90 8.83 180 0.01222 0.04222 0.04000 2.20 7,60 7,9 0.04167 7.9 60 2.50 2,40 0.04292 7.86 240 0.00667 1.60 10.30 0.50 1.20 7.93 60 0.00833 0.04167 2.50 41 0.02927 0.04634 1.90 7.96 0.04667 8 60 0.04167 2.50 2.80 120 0.01167 0.04667 1.40 5,60 8.08 60 0.06167 0.04167 3.70 2.50 7.9 60 0.04333 0.04333 0.04278 260 2.60 8.01 360 0.01083 3.90 15.40 0.04667 120 0.02000 2.40 5.60 7.97 0.01444 8.15 180 0.04944 2.60 8.90 1.40 60 0.02333 0.04333 2.60 8.27 0.04000 60 0.04000 2.40 2,40 8.55 60 0.04167 0.04333 2.50 2.60 8.66 60 2 0.04667 0.04667 2.80 2.80 8.17 4 0.04167 60 0.04833 2.90 2.50 8.06 4 60 0.01500 0.04167 0.90 2.50 8.55 4 0.04167 0.04500 60 0.05833 3.50 2.50 8.11 120 4 0.01667 0.05667 0.00500 2.00 5.40 8.17 4 0.04000 60 3.40 2,40 8.06 120 13 1 0.03917 0.60 4.70 6.98 0.00432 13 717 1 0.04114 3.10 29.50 7.08 13 1,500 1 0.00633 0.04273 9.50 64.10 2,475 83.00 7.2 13 1 0.00909 0.03354 22.50 0.01000 7.25 13 240 1 0.04750 2.40 11.40 6.47 13 882 0.01780 0.03016 0.03608 15.70 26.60 13 1.677 0.01109 18.60 60.50 7.04 13 243 2 0.00206 0.04568. 0.50 11.10 7.05 NNNNNNT

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts