Question: Using the information in the Job Sequencing Exercise, and the sequences assigned below, create two Gantt Charts by loading the work centers with the available

Using the information in the Job Sequencing Exercise, and the sequences assigned below, create two Gantt Charts by loading the work centers with the available jobs. Based on your schedules, show the make spans, average total queue time across all jobs, and the total profit (loss) for your schedules. Briefly comment on your results.

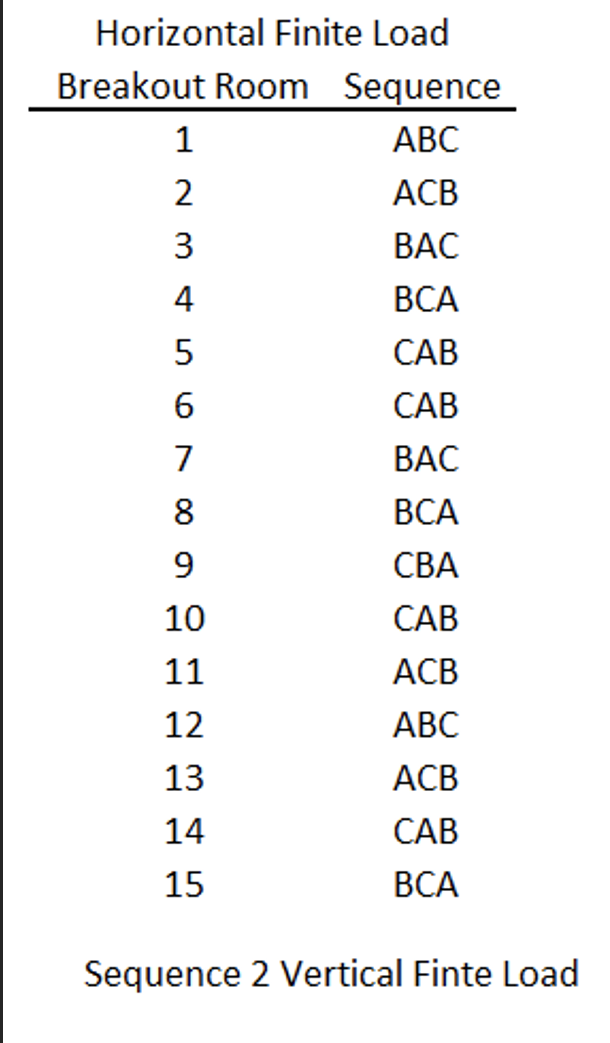

Priority sequence and type of loading to use in developing your schedule:

USE ONLY BREAKOUT ROOM 8 INFORMATION PLEASE.

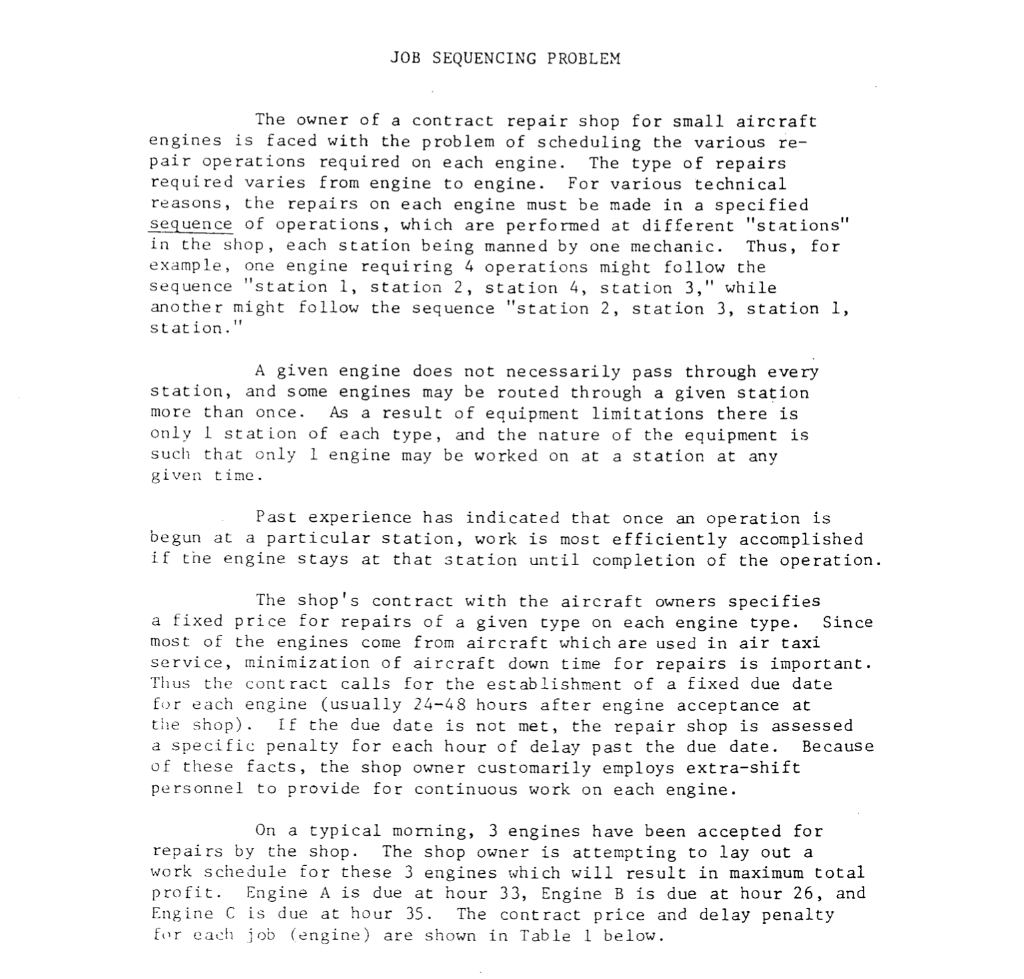

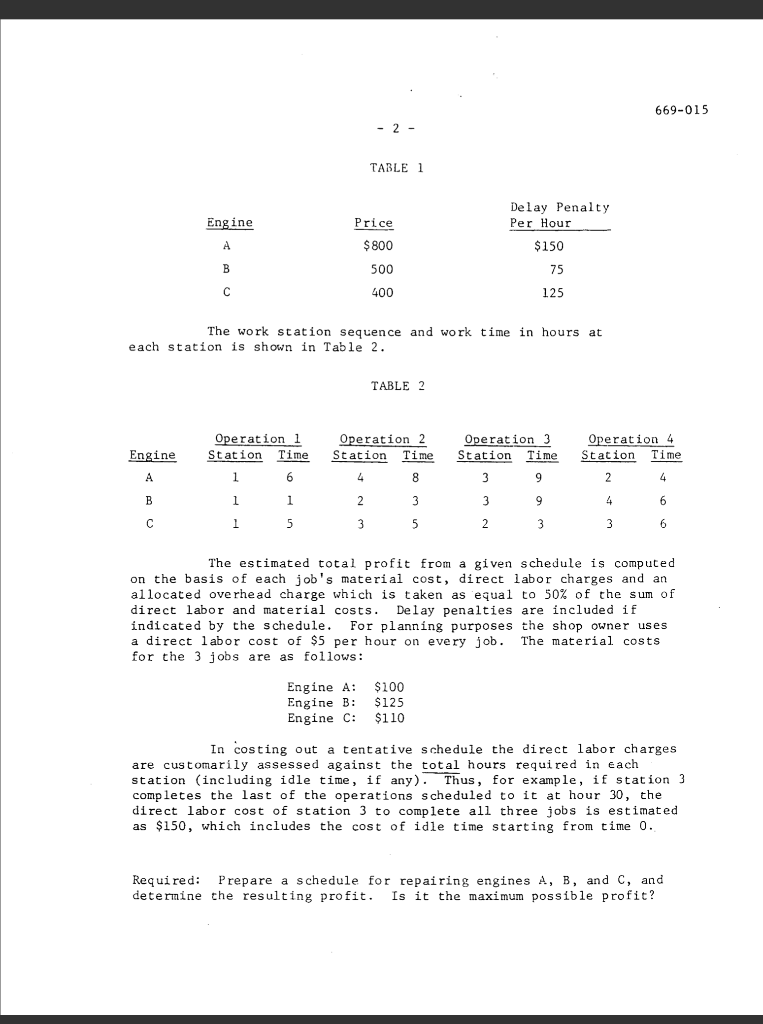

JOB SEQUENCING PROBLEM The owner of a contract repair shop for small aircraft engines is faced with the problem of scheduling the various re- pair operations required on each engine. The type of repairs required varies from engine to engine. For various technical reasons, the repairs on each engine must be made in a specified sequence of operations, which are performed at different "stations" in the shop, each station being manned by one mechanic. Thus, for example, one engine requiring 4 operations might follow the sequence "station 1, station 2, station 4, station 3," while another might follow the sequence "station 2, station 3, station 1, station. 1 A given engine does not necessarily pass through every station, and some engines may be routed through a given station more than once. As a result of equipment limitations there is only I station of each type, and the nature of the equipment is such that only l engine may be worked on at a station at any given time. Past experience has indicated that once an operation is begun at a particular station, work is most efficiently accomplished if the engine stays at that station until completion of the operation. The shop's contract with the aircraft owners specifies a fixed price for repairs of a given type on each engine type. Since most of the engines come from aircraft which are used in air taxi service, minimization of aircraft down time for repairs is important. Thus the contract calls for the establishment of a fixed due date for each engine (usually 24-48 hours after engine acceptance at the shop). If the due date is not met, the repair shop is assessed a specific penalty for each hour of delay past the due date. Because of these facts, the shop owner customarily employs extra-shift personnel to provide for continuous work on each engine. On a typical morning, 3 engines have been accepted for repairs by the shop. The shop owner is attempting to lay out a work schedule for these 3 engines which will result in maximum total profit. Engine A is due at hour 33, Engine B is due at hour 26, and Engine C is due at hour 35. The contract price and delay penalty for each job (engine) are shown in Table I below. 669-015 - 2 - TABLE 1 Engine A Price $800 Delay Penalty Per Hour $150 B 500 75 400 125 The work station sequence and work time in hours at each station is shown in Table 2. TABLE 2 Operation 1 Station Time 1 6 Engine A Operation 4 Station Time Operation 2 Station Time 4 8 2 3 3 3 5 Operation 3 Station Time 3 9 2 4 B 1 1 3 9 4 6 1 5 2 2 3 3 3 6 The estimated total profit from a given schedule is computed on the basis of each job's material cost, direct labor charges and an allocated overhead charge which is taken as equal to 50% of the sum of direct labor and material costs. Delay penalties are included if indicated by the schedule. For planning purposes the shop owner uses a direct labor cost of $5 per hour on every job. The material costs for the 3 jobs are as follows: Engine A: $100 Engine B: $125 Engine C: $110 In costing out a tentative schedule the direct labor charges are customarily assessed against the total hours required in each station (including idle time, if any). Thus, for example, if station 3 completes the last of the operations scheduled to it at hour 30, the direct labor cost of station 3 to complete all three jobs is estimated as $150, which includes the cost of idle time starting from time 0. a Required: Prepare a schedule for repairing engines A, B, and C, and determine the resulting profit. Is it the maximum possible profit? Horizontal Finite Load Breakout Room Sequence 1 2 ACB 3 BAC 4 5 6 7 BAC 8 9 10 11 ACB 12 13 ACB 14 15 Sequence 2 Vertical Finte LoadStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock