Question: uu Table 6.6 Lead time observations for solved Problem 6.2 Frequency (Number of times this lead time Lead time (days) has been observed) Lead time

uu

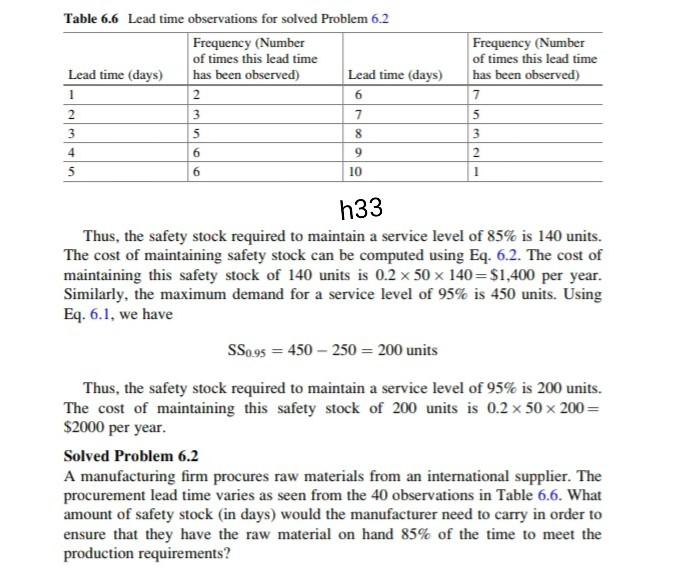

Table 6.6 Lead time observations for solved Problem 6.2 Frequency (Number of times this lead time Lead time (days) has been observed) Lead time (days) 1 2 2 3 7 5 6 9 5 6 Frequency (Number of times this lead time has been observed) 7 5 3 2 1 CI 3 8 4 6 10 h33 Thus, the safety stock required to maintain a service level of 85% is 140 units. The cost of maintaining safety stock can be computed using Eq. 6.2. The cost of maintaining this safety stock of 140 units is 0.2 x 50 x 140 = $1,400 per year. Similarly, the maximum demand for a service level of 95% is 450 units. Using Eq. 6.1, we have SS095 = 450 - 250 = 200 units Thus, the safety stock required to maintain a service level of 95% is 200 units. The cost of maintaining this safety stock of 200 units is 0.2 x 50 x 200 = $2000 per year. Solved Problem 6.2 A manufacturing firm procures raw materials from an international supplier. The procurement lead time varies as seen from the 40 observations in Table 6.6. What amount of safety stock (in days) would the manufacturer need to carry in order to ensure that they have the raw material on hand 85% of the time to meet the production requirementsStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock